A die-casting device and method for aluminum alloy die-casting parts

A die-casting and aluminum alloy technology, which is applied in the field of die-casting, can solve the problems of formability (poor casting performance, difficulty in obtaining high-density castings, mixed gas, etc.), and achieve the effects of improving compactness, improving porosity, and air elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

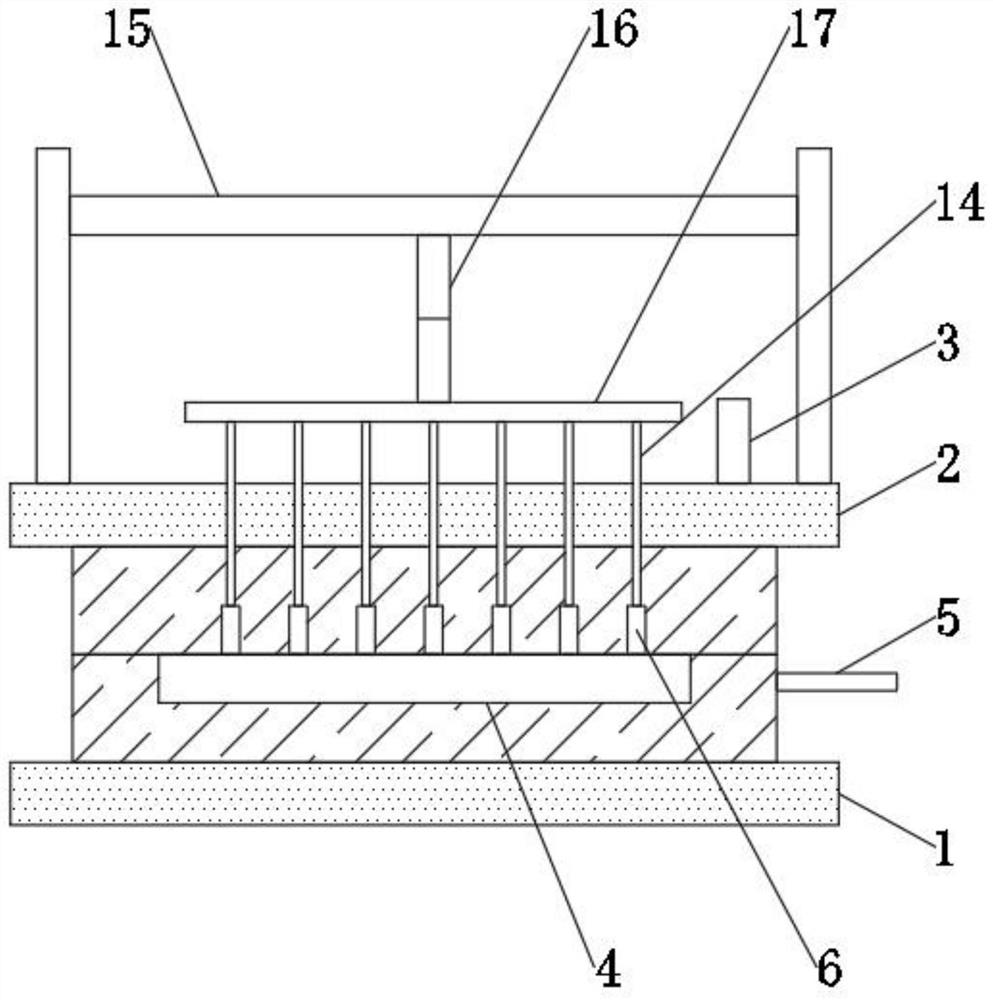

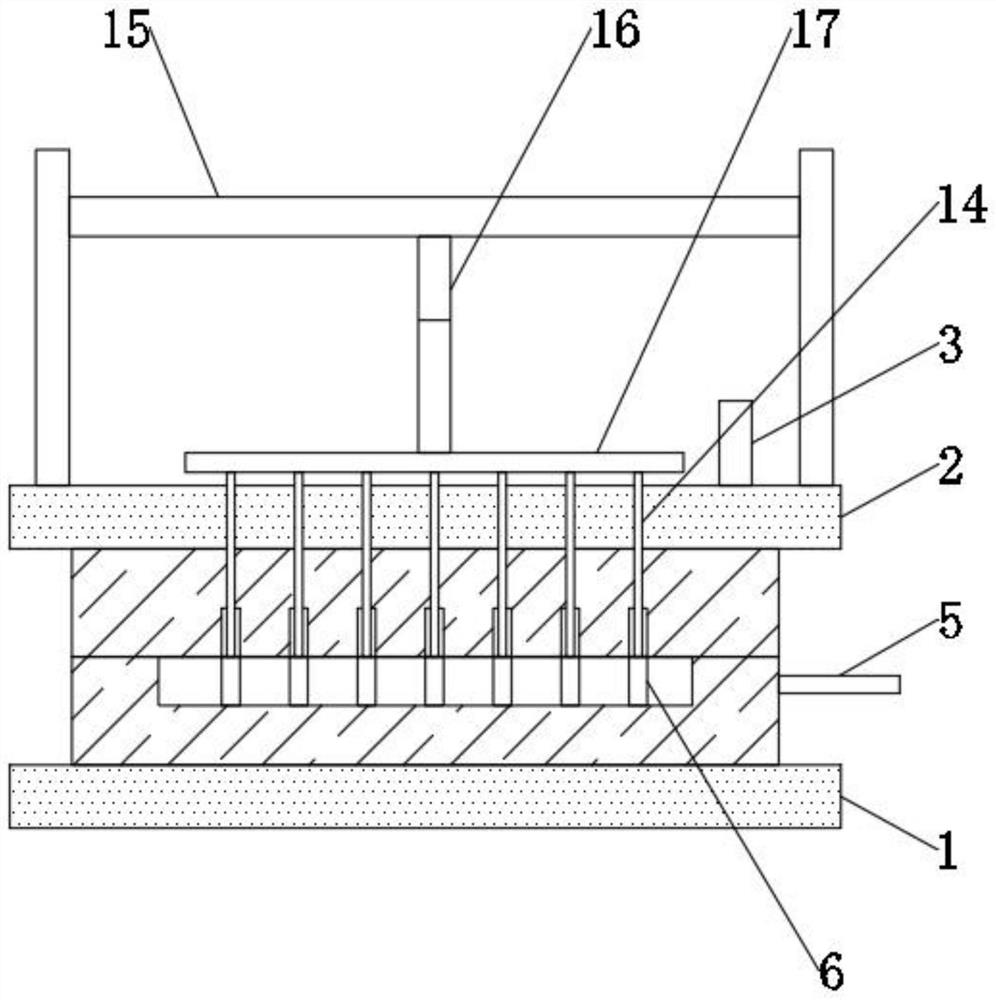

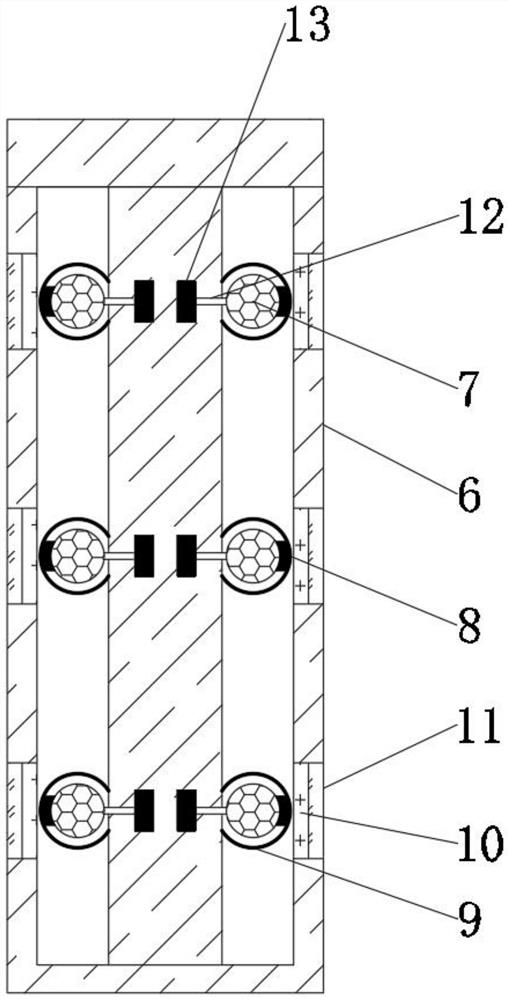

[0048] see Figure 1-4 , a die casting device for aluminum alloy die castings, comprising a fixed mold 1 and a movable mold 2, a cavity 4 is formed between the fixed mold 1 and the movable mold 2, a gate 3 is installed on the upper end of the movable mold 2, and a gate 3 is installed on the upper end of the fixed mold 1 There is an exhaust pipe 5, and a plurality of uniformly distributed migration holes are opened on the movable mold 2, and a matching air getter 6 is slidably connected in the migration hole. Mounting frame 15, the lower end of the mounting frame 15 is equipped with a hydraulic rod 16, the lower end of the hydraulic rod 16 is connected with a synchronous plate 17, and the synchronous plate 17 is connected with a plurality of transmission rods 14, the air getter 6 is connected with a central column, and the central column is inlaid and connected There are a plurality of evenly distributed static repulsion magnets 13, the outer end of the static repulsion magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com