Spot welding quality monitoring device and method based on dynamic machine vision

A machine vision and quality monitoring technology, applied in welding monitoring devices, welding power sources, welding equipment, etc., can solve problems such as the inability to guarantee 100% solder joint inspection, the inability to meet the needs of fast-paced production, and the poor timeliness of quality feedback. Rich and perfect welding process and low hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0039] see Figure 1-10 .

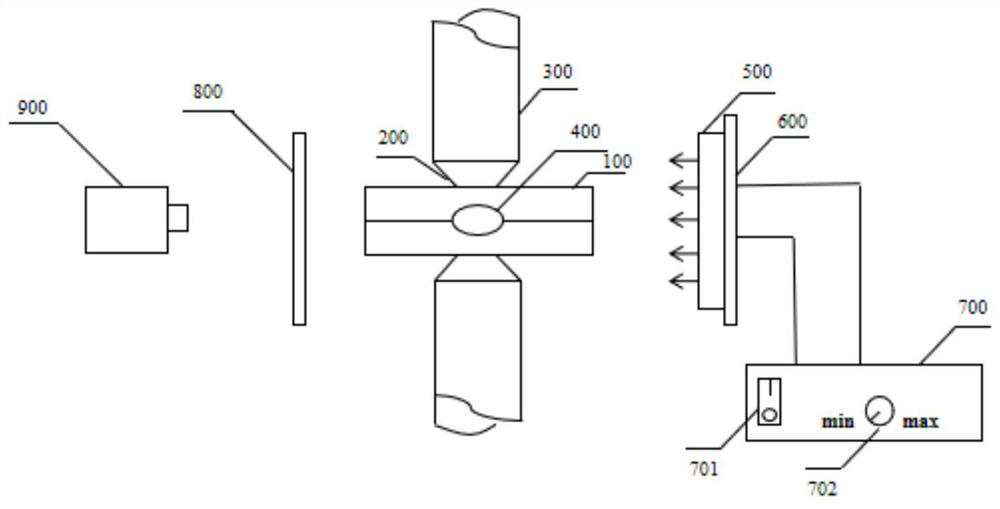

[0040] The invention discloses a spot welding quality monitoring device based on dynamic machine vision, such as figure 1 As shown, the workpiece 100 to be welded is placed between two identical spot welding electrodes 200, and the verticality between the electrode rod 300 and the workpiece 100 to be welded is 90°, which ensures the best spot welding angle and nugget position 400 is located at the center of the workpiece, so as to ensure that the pressure applied to the workpiece 100 to be welded is uniform during the spot welding process. The industrial square light source 500 is parallel to the right side of the workpiece 100 to be welded. The industrial square light source 500 can provide bright and uniform irradiation light and is fixed by the light source fixing frame 600 to keep it stable. The light source trigger simulator 700...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com