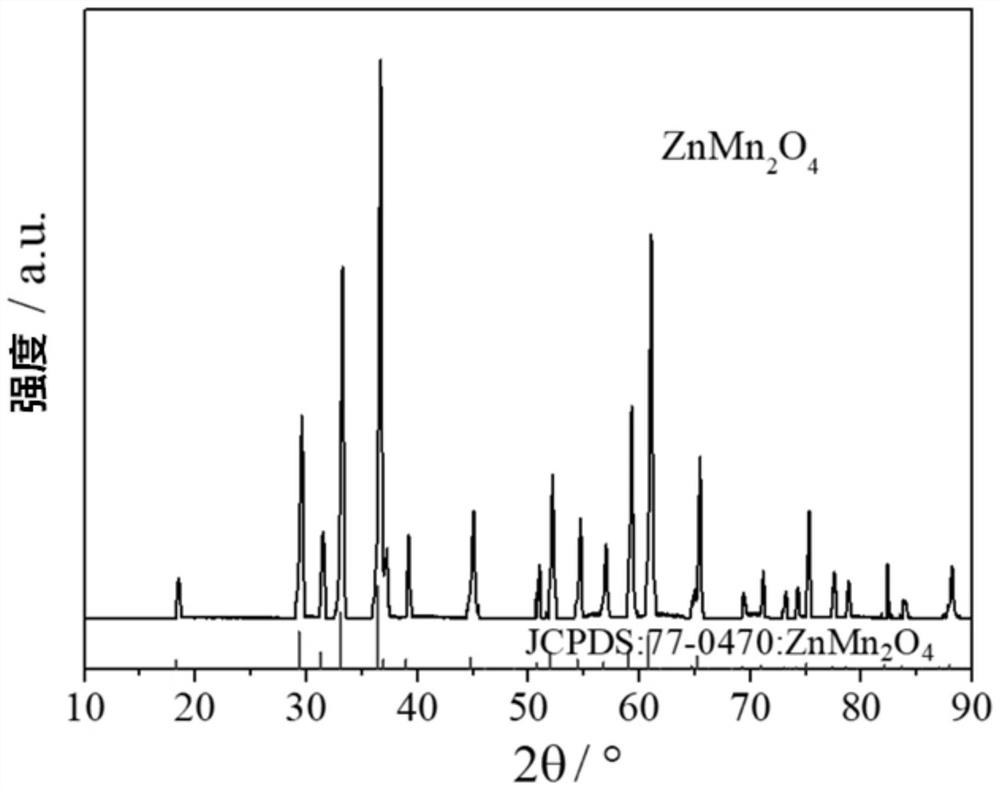

Zinc manganate negative electrode material, method for preparing zinc manganate negative electrode material by adopting coprecipitation method and application of zinc manganate negative electrode material

A negative electrode material, co-precipitation technology, applied in manganate/permanganate, battery electrodes, structural parts, etc., can solve the problems of high cost and complicated preparation process, achieve high reversible capacity, promote rapid diffusion, The effect of low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

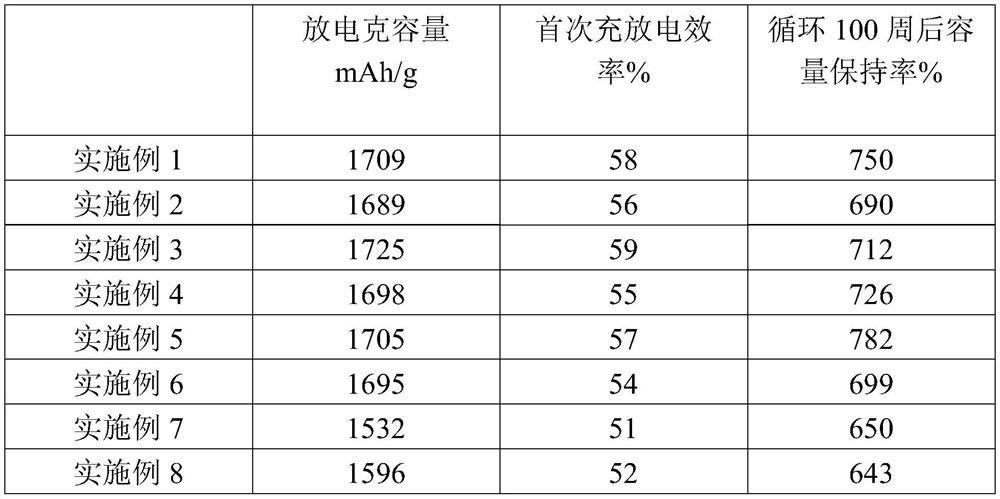

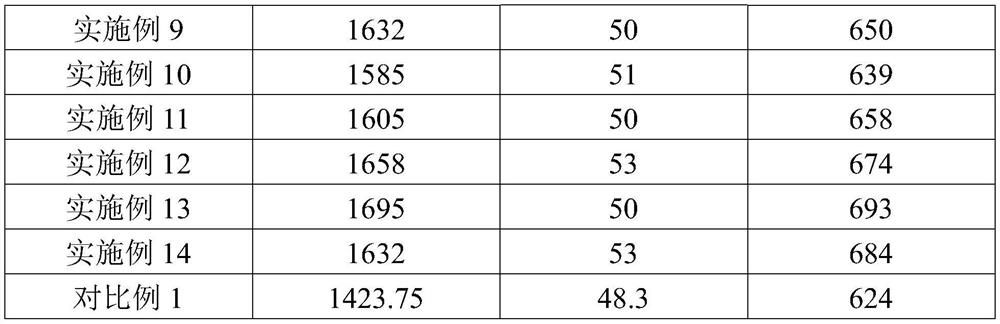

Examples

Embodiment 1

[0048] This embodiment provides a co-precipitation method to prepare ZnMn 2 o 4 The method of negative electrode material, described method specifically comprises:

[0049] (1) Zinc sulfate and manganese sulfate according to ZnMn 2 o 4 The stoichiometric ratio is weighed and dissolved in deionized water to form a mixed salt solution. The molar ratio of zinc in the zinc source and manganese in the manganese source is 1:2; add 0.3mol / L coprecipitant ammonia water In the constant pressure burette, add ammoniacal liquor dropwise to the mixed salt solution, the rate of addition of ammoniacal liquor is controlled by the constant pressure burette to be 2s / drop, in the process of dripping ammoniacal liquor, the mixed salt solution is continuously stirred to obtain the precipitate, the stirring speed 300r / min, the total dripping amount of ammonia is 15wt% of the total mass of the mixed salt solution;

[0050] (2) The precipitate was aged for 10 hours, then filtered, washed once wit...

Embodiment 2

[0052] This embodiment provides a co-precipitation method to prepare ZnMn 2 o 4 The method of negative electrode material, described method specifically comprises:

[0053] (1) Zinc chloride and manganese chloride according to ZnMn 2 o 4 The stoichiometric ratio was weighed and dissolved in deionized water to form a mixed salt solution. The molar ratio of the zinc element in the zinc source and the manganese element in the manganese source was 1:2; add 0.32mol / L coprecipitant ammonia water In the constant pressure burette, add ammoniacal liquor dropwise to the mixed salt solution, the rate of addition of ammoniacal liquor is controlled by the constant pressure burette to be 2s / drop, in the process of dripping ammoniacal liquor, the mixed salt solution is continuously stirred to obtain the precipitate, the stirring speed It is 320r / min, and the total dripping amount of ammoniacal liquor is 16wt% of the total mass of mixed salt solution;

[0054] (2) The precipitate was aged...

Embodiment 3

[0056] This embodiment provides a co-precipitation method to prepare ZnMn 2 o 4 The method of negative electrode material, described method specifically comprises:

[0057] (1) Zinc nitrate and manganese nitrate according to ZnMn 2 o 4 The stoichiometric ratio was weighed and dissolved in deionized water to form a mixed salt solution. The molar ratio of the zinc element in the zinc source and the manganese element in the manganese source was 1:2; add 0.34mol / L coprecipitant ammonia water In the constant pressure burette, dropwise add ammoniacal liquor to the mixed salt solution, control the drip rate of ammoniacal liquor to be 3s / drop through the constant pressure burette, in the process of dripping ammoniacal liquor, carry out continuous stirring to the mixed salt solution to obtain the precipitate, the stirring speed 340r / min, the total dripping amount of ammonia is 20wt% of the total mass of the mixed salt solution;

[0058] (2) The precipitate was aged for 12 hours, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com