Synthesis process and synthesis equipment for mixture of buprofezin intermediate tert-butyl thiocyanate and tert-butyl isocyanate

A technology of bulk thiocyanate and synthesis process, which can be used in the preparation of isocyanic acid derivatives, the preparation of organic compounds, chemical instruments and methods, etc. Carbon disulfide, the effect of improving stability and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

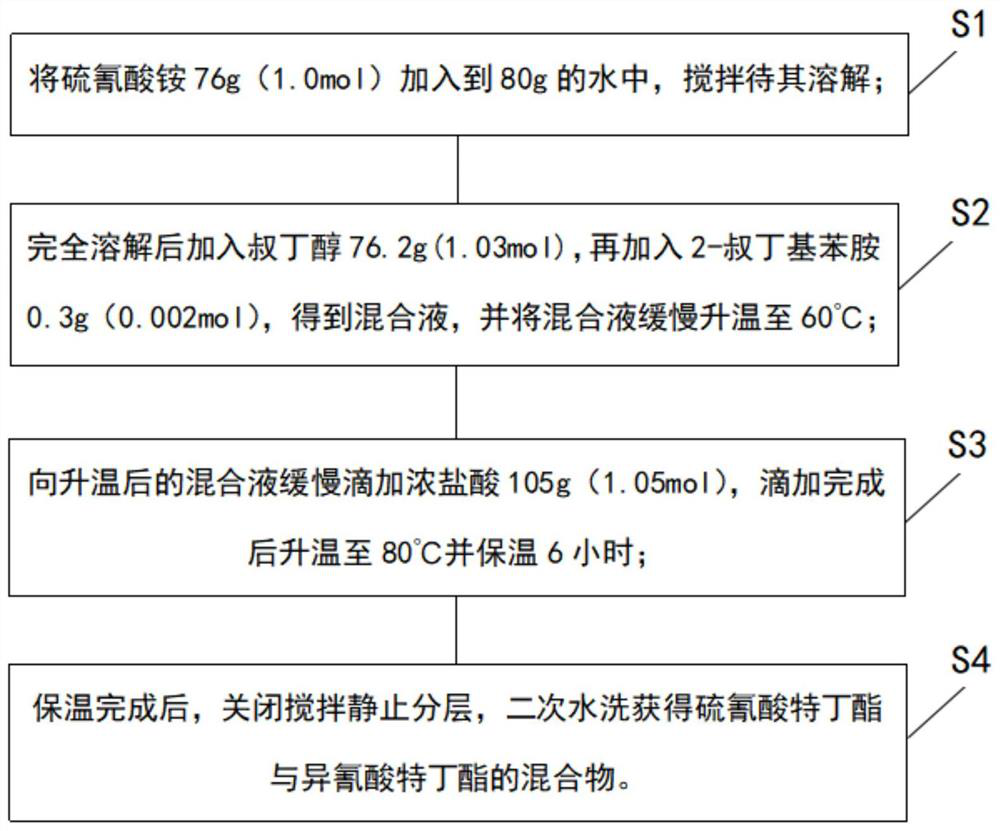

[0026] Example 1, see figure 1 , the present invention provides a technical solution: a synthesis process of a mixture of buprofezin intermediate tert-butyl thiocyanate and tert-butyl isocyanate, comprising the following steps:

[0027] S1: Ammonium thiocyanate 76g (1.0mol) is joined in the water of 80g, stir until it dissolves;

[0028] S2: After completely dissolving, add 76.2g (1.03mol) of tert-butanol, then add 0.3g (0.002mol) of 2-tert-butylaniline to obtain a mixed solution, and slowly raise the temperature of the mixed solution to 60°C;

[0029] S3: Slowly add 105 g (1.05 mol) of concentrated hydrochloric acid dropwise to the heated mixed solution, and after the dropwise addition is completed, the temperature is raised to 80° C. and kept for 6 hours;

[0030] S4: After the heat preservation is completed, the stirring is turned off and the stratification is static, and the mixture of tert-butyl thiocyanate and tert-butyl isocyanate is obtained by washing twice.

[0031...

Embodiment 2

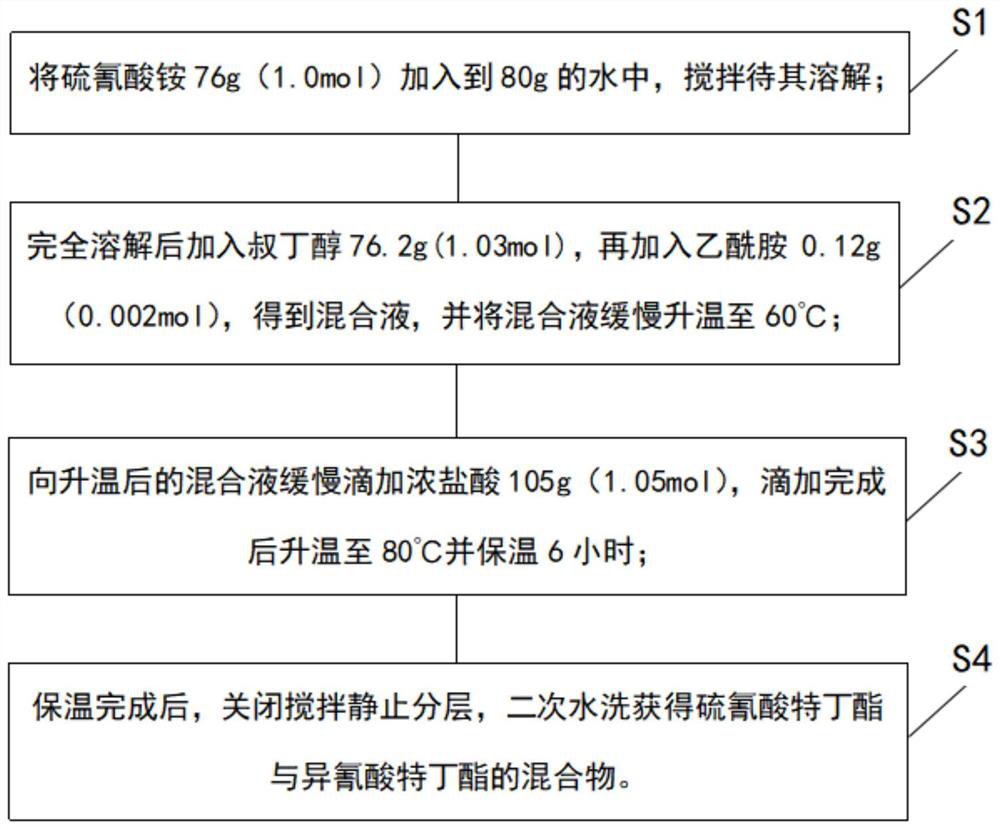

[0035] Example 2, see figure 2 , the present invention provides a technical solution: a synthesis process of a mixture of buprofezin intermediate tert-butyl thiocyanate and tert-butyl isocyanate, comprising the following steps:

[0036] S1: Ammonium thiocyanate 76g (1.0mol) is joined in the water of 80g, stir until it dissolves;

[0037] S2: After complete dissolution, add 76.2g (1.03mol) of tert-butanol, then add 0.12g (0.002mol) of acetamide to obtain a mixed solution, and slowly raise the temperature of the mixed solution to 60°C;

[0038] S3: Slowly add 105 g (1.05 mol) of concentrated hydrochloric acid dropwise to the heated mixed solution, and after the dropwise addition is completed, the temperature is raised to 80° C. and kept for 6 hours;

[0039] S4: After the heat preservation is completed, the stirring is turned off and the stratification is static, and the mixture of tert-butyl thiocyanate and tert-butyl isocyanate is obtained by washing twice.

[0040] Wherein...

Embodiment 3

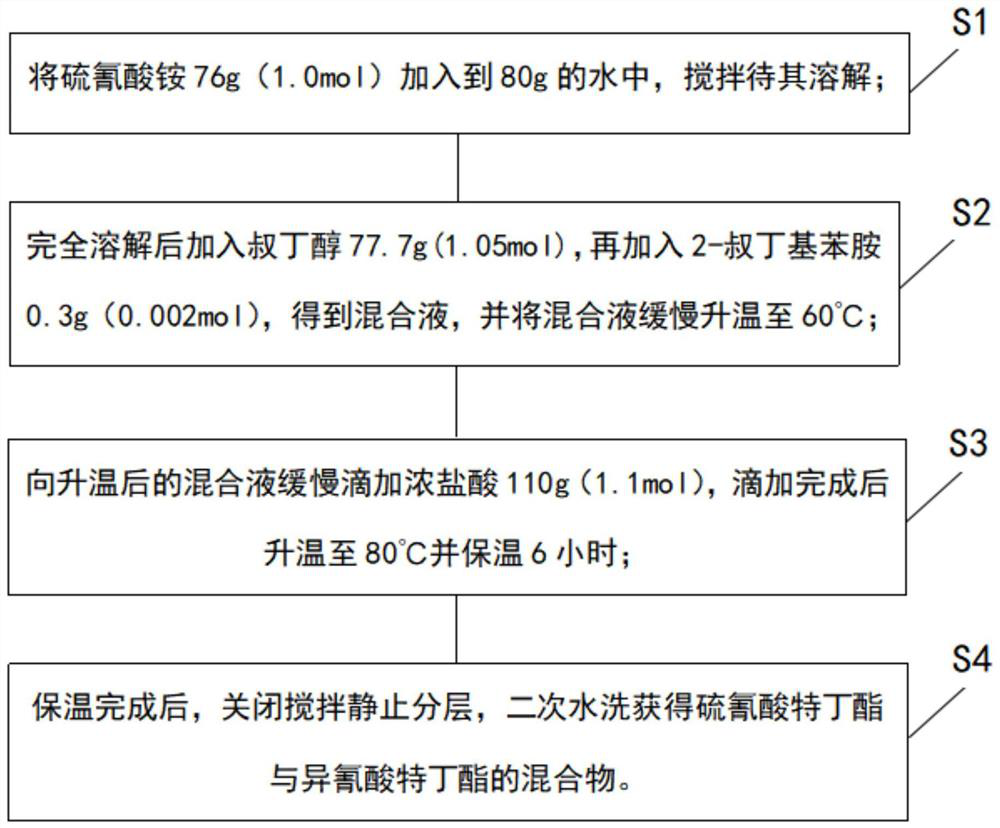

[0044] Example 3, see image 3 , the present invention provides a technical solution: a synthesis process of a mixture of buprofezin intermediate tert-butyl thiocyanate and tert-butyl isocyanate, comprising the following steps:

[0045] S1: Ammonium thiocyanate 76g (1.0mol) is joined in the water of 80g, stir until it dissolves;

[0046] S2: After completely dissolving, add 77.7g (1.05mol) of tert-butanol, then add 0.3g (0.002mol) of 2-tert-butylaniline to obtain a mixed solution, and slowly raise the temperature of the mixed solution to 60°C;

[0047] S3: Slowly add 110 g (1.1 mol) of concentrated hydrochloric acid dropwise to the heated mixed solution, and after the dropwise addition is completed, the temperature is raised to 80° C. and kept for 6 hours;

[0048] S4: After the heat preservation is completed, the stirring is turned off and the stratification is static, and the mixture of tert-butyl thiocyanate and tert-butyl isocyanate is obtained by washing twice.

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com