Underwater soft medium-oriented optical fiber topography change sensor

A sensor and terrain deformation technology, which is applied in the direction of instruments, water resources assessment, and optical devices, etc., can solve the problems of small measurement range, interference of sensor measurement results, and inability to measure local deformation in a distributed manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

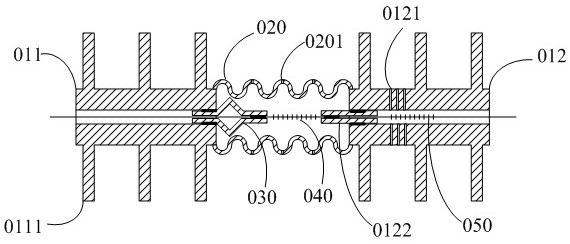

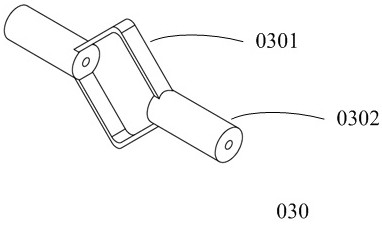

[0034] figure 1 A structural diagram of an optical fiber deformation sensor facing underwater soft media provided by the present invention, wherein, the first coupling structure 011, the coupling plate 0111, the second coupling structure 012, the static pressure hole 0121, the protrusion 0122, and the bellows 020 , static pressure microhole 0201, elastic connection structure 030, fiber Bragg grating 040, compensation fiber Bragg grating 050.

[0035] Both the first coupling structure 011 and the second coupling structure 012 are metal cylindrical structures, which are processed by metal, and contain multiple coupling pieces 0111 on the side wall, which can effectively improve the coupling strength with the soft medium; the first coupling structure 011 is in the A through hole is opened on the axis to allow the optical fiber to pass through and protect the internal optical fiber; the second coupling structure 012 is further processed with a protrusion 0122 on the central axis, ...

Embodiment 2

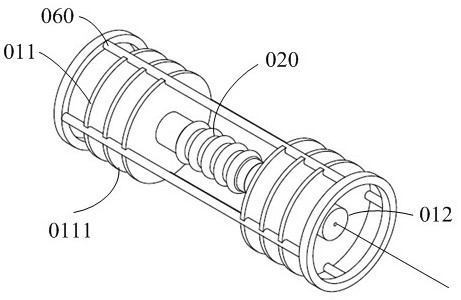

[0043] see image 3 , On the coupling sheet 0111 of the first coupling structure 011 and the second coupling structure 012, a support rod 060 is further pierced, wherein the support rod 060 is a metal structure, and a frame is formed by welding or screwing, and the support rod 060 and the first Both the coupling piece 0111 of the coupling structure 011 and the second coupling structure 012 are slidingly connected. When the lateral force is applied, under the protection of the support rod 060, the sensor is not easily deformed, so that the bending resistance performance is improved. When the axial force is received When functioning, the support rod 060 slides with the sensor, and the sensor is prone to deformation, thereby ensuring the measurement sensitivity without affecting the measurement accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com