Thermoelectric coupling modeling method of power semiconductor chip cell

A power semiconductor and thermoelectric coupling technology, applied in CAD numerical modeling, electrical digital data processing, instruments, etc., can solve the problem of accurate characterization of chip electrical characteristics, prediction of chip electrical temperature field accuracy disadvantages, and complex application environment of power semiconductor chips And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to explain the present invention in more detail, the present invention will be further described in detail below in conjunction with the accompanying drawings, taking the SEMiKron power semiconductor module SEMiX603GB12E4p as an example.

[0057] The thermoelectric coupling modeling method of the power semiconductor chip cell proposed by the present invention, the specific steps include:

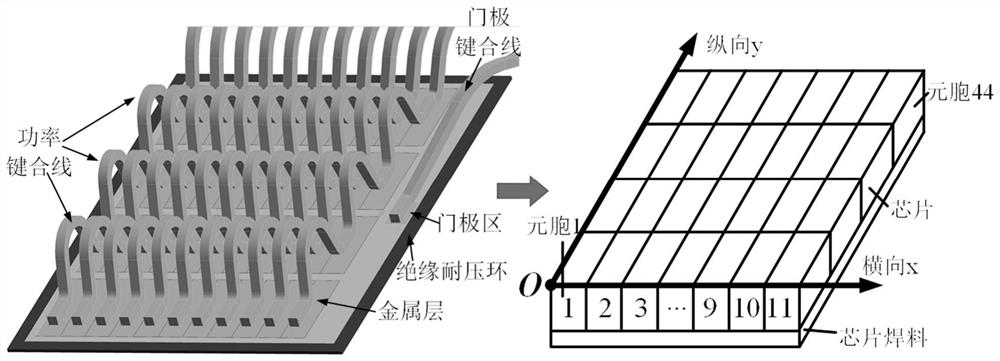

[0058] S1. Based on the chip metal layer and bonding wire layout characteristics, the power semiconductor chip is divided into a multi-cell structure;

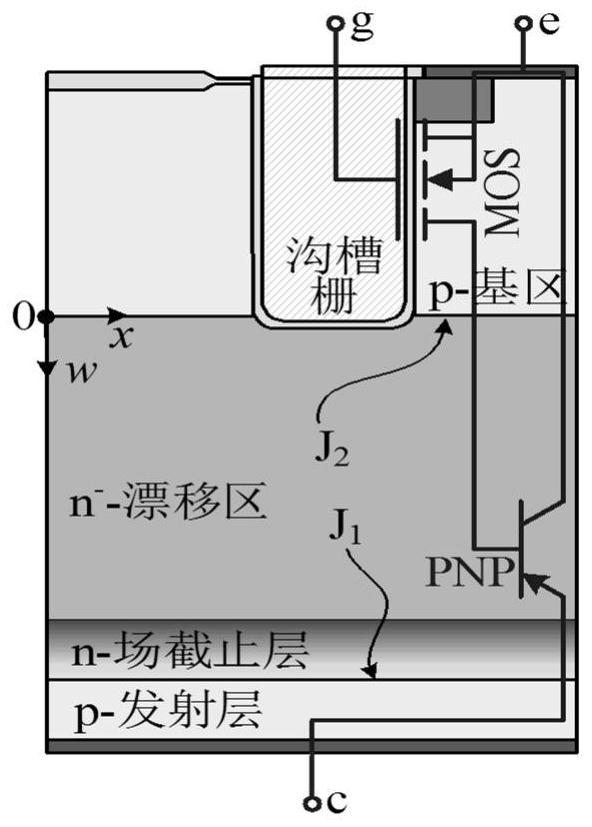

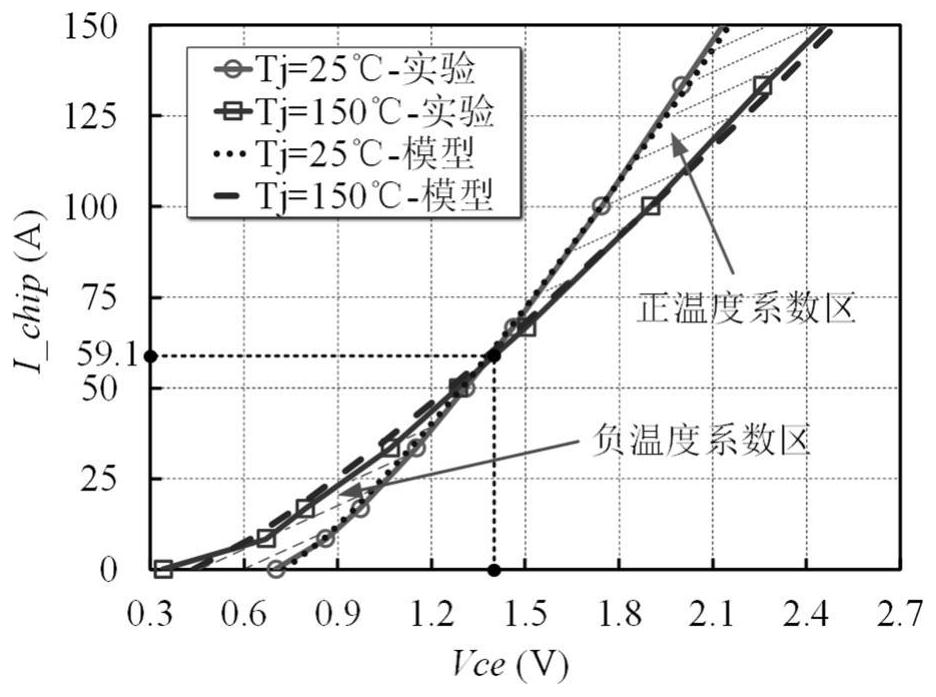

[0059] S2. Extract chip lumped parameters, and use the least squares algorithm to establish a voltage-current-temperature three-dimensional model of the power semiconductor chip;

[0060] S3. According to the characteristics of the multi-cell parallel circuit, the chip lumped parameters are converted into cell distribution parameters, and the voltage-current-temperature three-dimensional model of the power semiconductor cell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com