Self-adaptive rigid-flexible dual-state fireproof cable

A fireproof cable, self-adaptive technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of internal insulation cracking, inconvenient construction of steel fireproof cables, long fire resistance time of cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

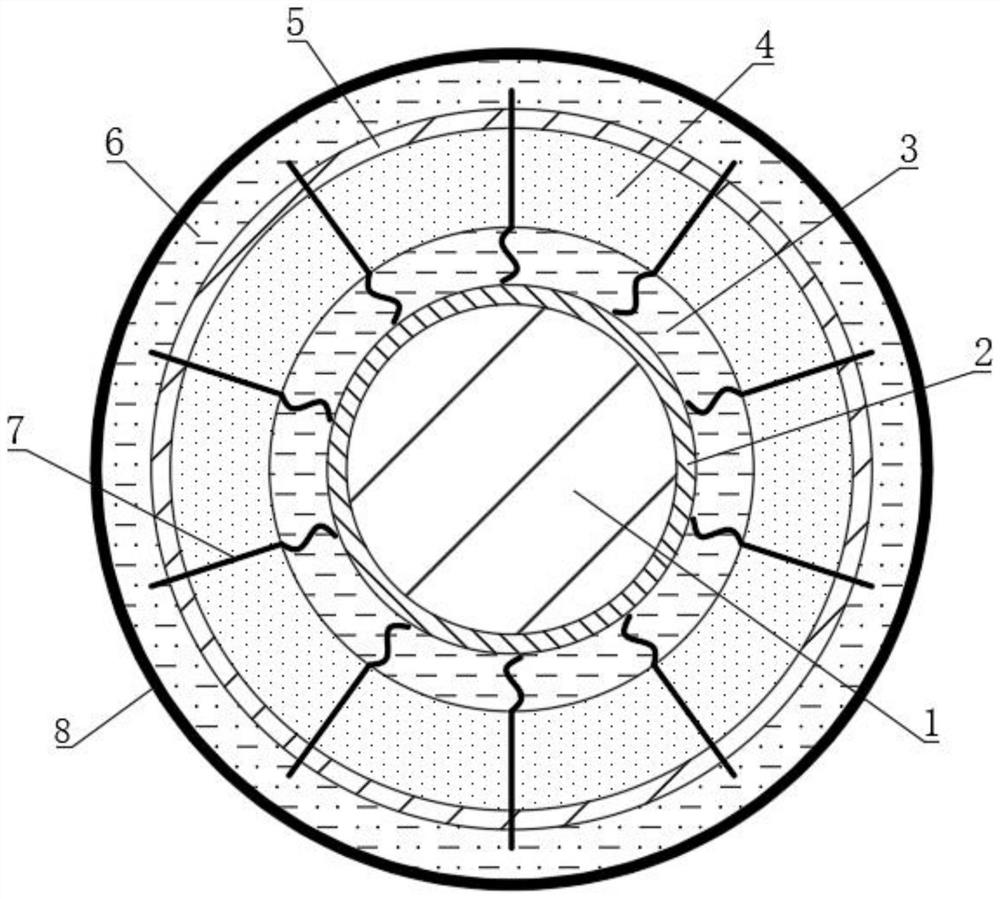

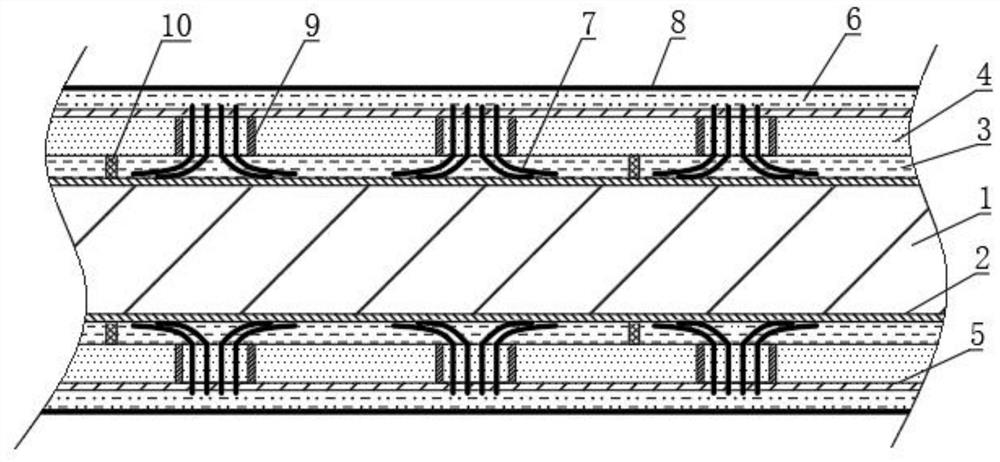

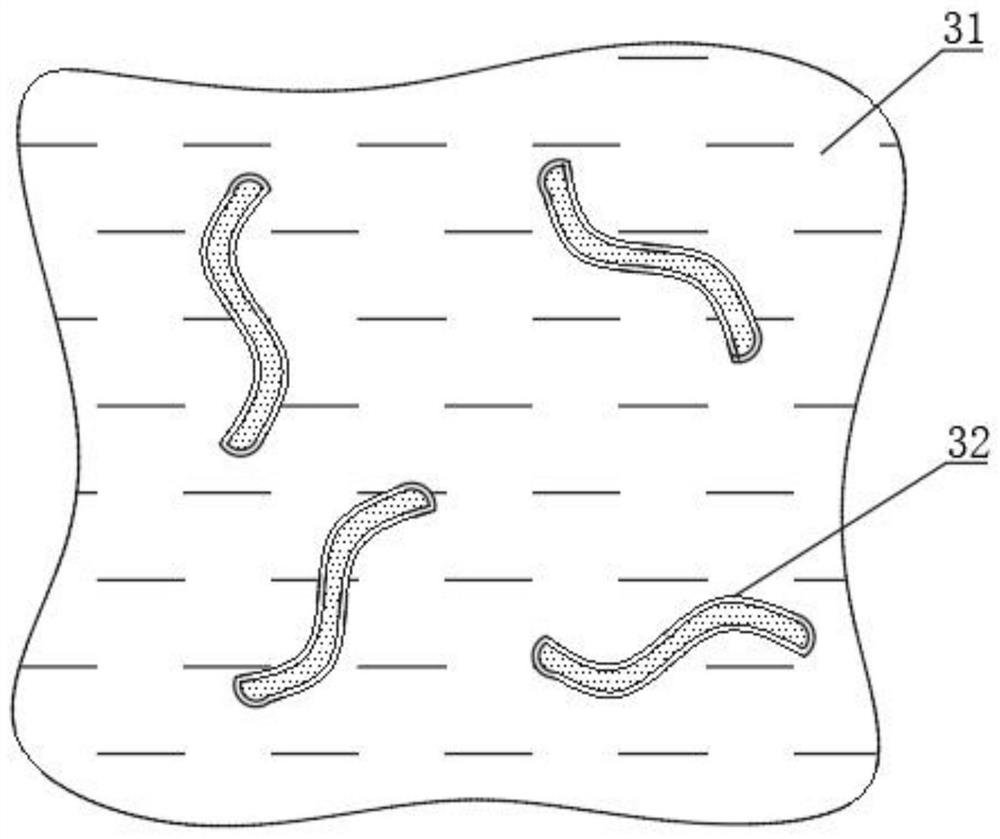

[0039] see figure 1 and figure 2 , an adaptive rigid-flexible dual-state fireproof cable, including a cable core 1, a flexible insulating sheath 6 is sheathed on the outer side of the cable core 1, and internal liquid barriers are sequentially arranged between the cable core 1 and the flexible insulating sheath 6 from inside to outside Sleeve 2, outer liquid isolation sleeve 4 and heat insulation protection layer 5, the inner surface of the inner liquid isolation sleeve 2 is fixedly connected with the outer surface of the cable core 1, and the heat insulation protection layer 5 is fixedly connected with the flexible insulating sheath 6 and the outer liquid isolation layer Between the sleeves 4, a thermosetting filling liquid 3 is filled between the inner liquid-separating sleeve 2 and the outer liquid-separating sleeve 4, and the inside of the outer liquid-separating sleeve 4 is fixedly connected with a plurality of evenly distributed heat-conducting and air-filtering soft wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com