Vehicle fuel cell air system with cold start function and control method of vehicle fuel cell air system

A fuel cell and air system technology, applied in power system fuel cells, fuel cells, fuel cell additives, etc., can solve problems such as reduced discharge capacity, cold start failure, and reduced electrochemically active surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

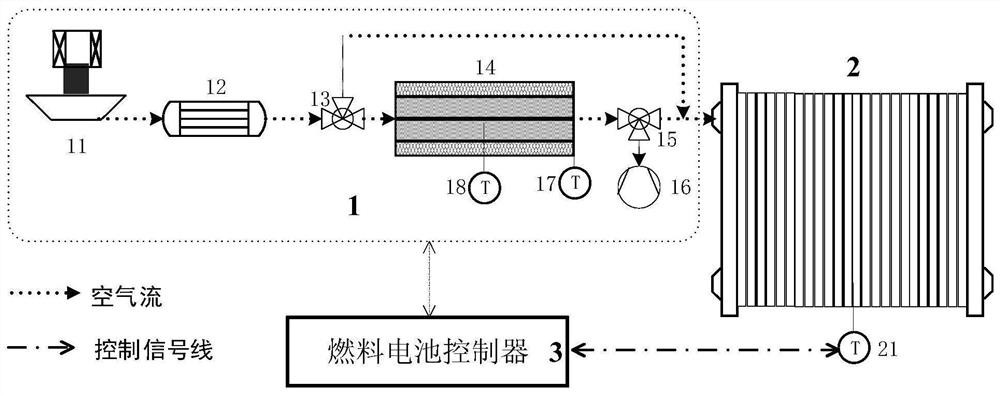

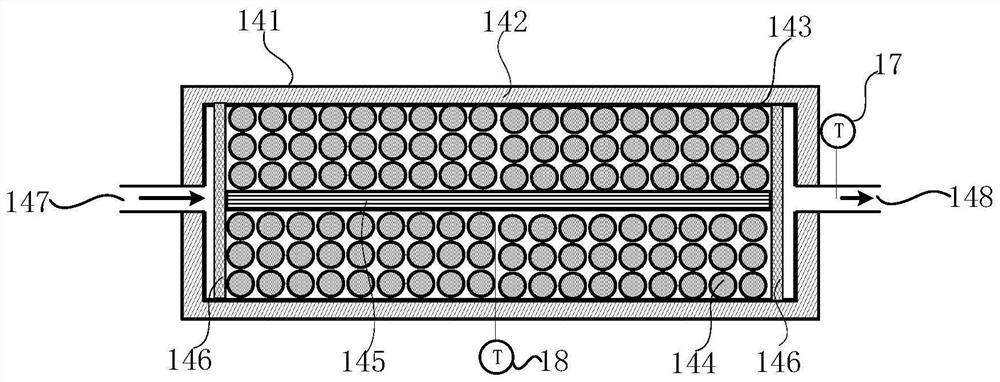

[0034] Embodiment 1 of the present invention provides a vehicle fuel cell air system with cold start function, such as figure 1 As shown, it includes an air supply unit 1, a fuel cell stack 2 and a fuel cell controller 3, the air supply unit 1 is connected to the fuel cell stack 2, and the fuel cell controller 3 is respectively connected to the air supply unit 1, The fuel cell stack 2 is connected in communication; the air supply unit 1 includes a solid adsorption heat storage device 14;

[0035] In this way, the solid adsorption heat accumulator 14 is used for preheating the fuel cell stack 2 through the heat of adsorption released by the adsorbent adsorbing the adsorbate during the cold start of the vehicle fuel cell, so as to help it quickly realize the cold start.

[0036] The air supply unit 1 further includes an air compressor 11, a humidifier 12, a first three-way solenoid valve 13, a second three-way solenoid valve 15, a vacuum pump 16, a first temperature sensor 17, a...

Embodiment 2

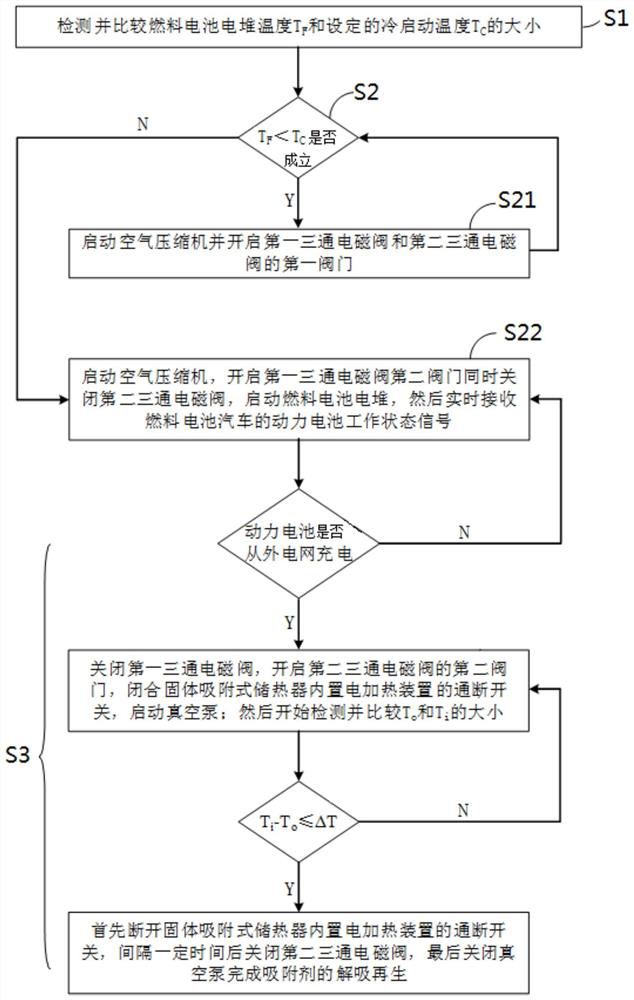

[0057] Embodiment 2 of the present invention provides a control method for a vehicle fuel cell air system with a cold start function, such as image 3 As shown, the method specifically includes the following steps:

[0058] S1, detecting the temperature T of the fuel cell stack 2 F , the temperature T of the fuel cell stack 2 F with the set cold start temperature T C Compare;

[0059] Specifically, the temperature inside the fuel cell is detected by the stack temperature sensor 21;

[0060] S2, according to the temperature T of the fuel cell stack 2 F with the set cold start temperature T C The size relationship of controls the working state of the air supply unit 1, specifically:

[0061] When the temperature T of the fuel cell stack 2 F Below the cold start temperature T C When starting at low temperature is required, enter S21, otherwise enter S22;

[0062] S21, respectively open the air compressor 11 and the first three-way solenoid valve 13 connected to the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com