Fuel cell cold start system based on liquid magnetic heat flow and control method

A technology of fuel cells and fuel cell stacks, which is applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., and can solve the problem of reduction of electrochemically active surface area, loss of electrochemically active area, and damage to fuel cell power generation performance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

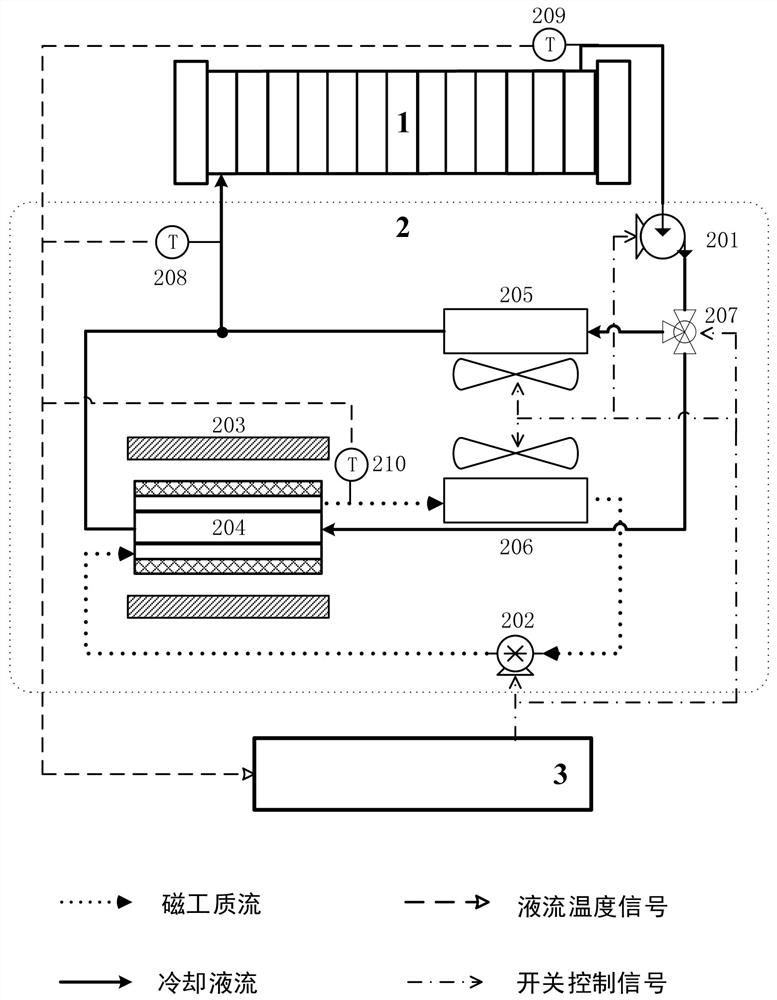

[0073] Example 1, in cold start mode,

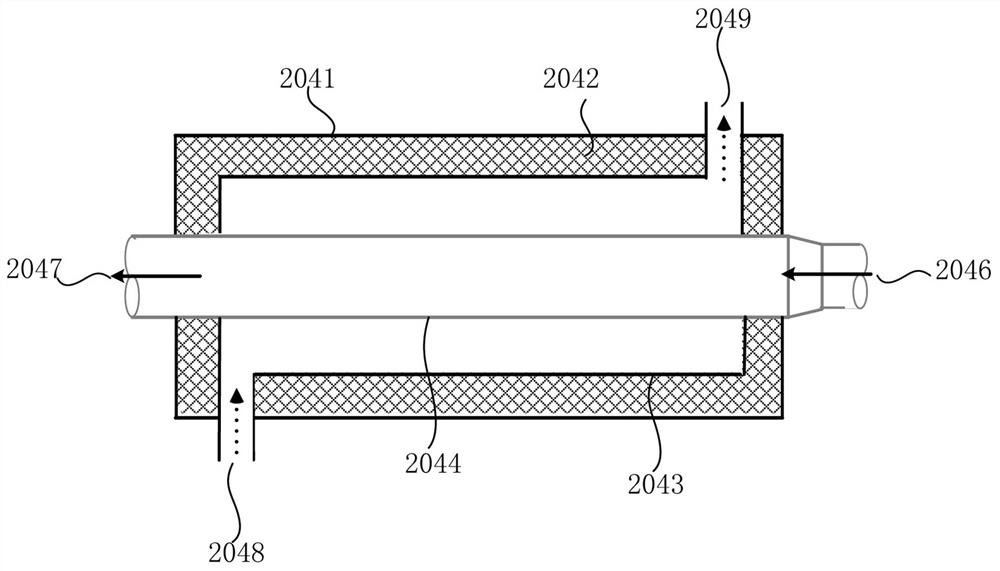

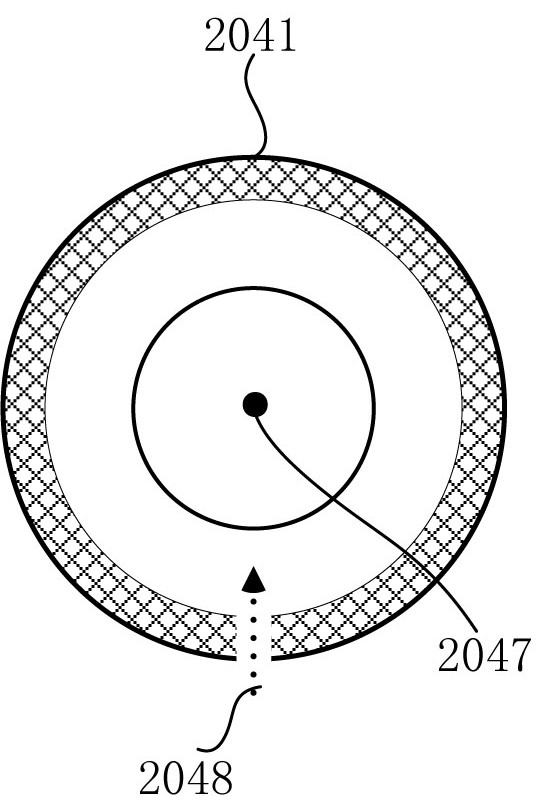

[0074] The thermal management controller 3 opens the second valve of the three-way solenoid valve 207 in the fuel cell thermal management unit 2, and then starts the first circulation pump 201 and the second circulation pump 202 respectively, so that the cooling liquid circuit of the fuel cell stack 1 The running trajectory is: first circulation pump 201 → three-way solenoid valve 207 → magnetic heat flow heat exchanger 204 → coolant temperature sensor 208 before the fuel cell stack inlet → fuel cell stack 1 → coolant temperature after the fuel cell stack outlet The sensor 209→the first circulation pump 201, thus forming the heat transfer fluid transfer circuit of the fuel cell stack;

[0075]The running track of the liquid magnetic substance is: second circulation pump 202→magnetic heat flow heat exchanger 204→third temperature sensor 210→second radiator 206→second circulation pump 202; during this process, the thermal management unit o...

Embodiment 2

[0076] Embodiment 2, in the normal thermal management mode, there are two different circulation paths for the coolant of the fuel cell stack 1, wherein,

[0077] When the fuel cell stack 1 has just completed low-temperature startup and has not yet reached the optimum operating temperature, the thermal management controller 3 turns off the second circulation pump 202 and the second radiator fan in the fuel cell thermal management unit 2, and maintains the first circulation The pump 201 and the second valve of the three-way solenoid valve 207 are still in an open state, so that the cooling fluid circulates according to the heat-carrying fluid transfer circuit of the aforementioned material-battery stack.

[0078] When the fuel cell stack 1 has entered the optimum operating temperature range, the thermal management controller 3 opens the first valve of the three-way solenoid valve 207 in the fuel cell thermal management unit 2, so that the cooling liquid circuit of the fuel cell s...

Embodiment 3

[0084] The above embodiments of the present invention also provide a control method for a fuel cell cold start system based on liquid magnetic heat flow, such as Figure 7 As shown, the method is implemented through the following steps:

[0085] In step 500, the thermal management controller 3 monitors the temperature T of the coolant passing through the fuel cell stack 1 F Value; in embodiment 1, thermal management controller 3 adopts T Fi and T Fo The average value of the fuel cell stack 1 coolant temperature T F value. Then, compare the fuel cell stack coolant temperature T F and the first threshold temperature T 1 and go to step 510.

[0086] In step 510, thermal management controller 3 monitors whether there is T F 1 If yes, go to step 511, otherwise go to step 520.

[0087] In step 511, the thermal management controller 3 turns on the second valve of the three-way solenoid valve 207 of the fuel cell thermal management unit 2, the first circulation pump 201, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com