Method for producing NFC juice through combination of ultrahigh pressure and tea polyphenols

An ultra-high pressure, tea polyphenol technology, applied in the field of food safety, can solve the problems of reducing the pressure required for sterilization, prolonging the shelf life of juice, and high production costs, reducing energy consumption, improving the sterilization effect, and reducing the temperature variation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

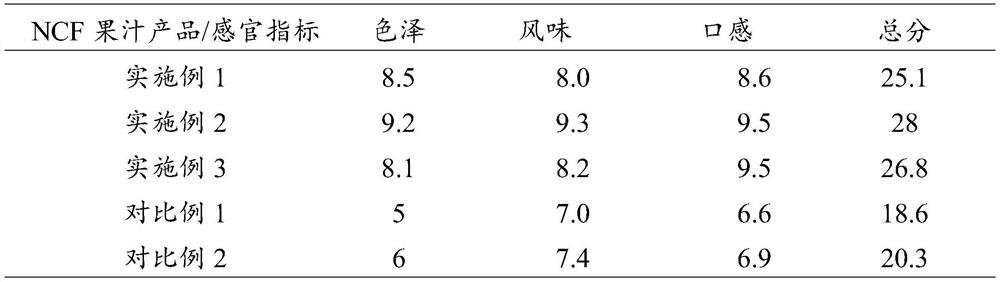

Embodiment 1

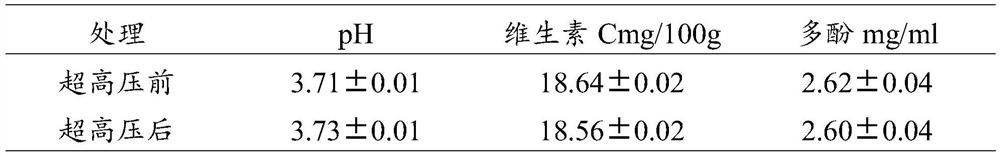

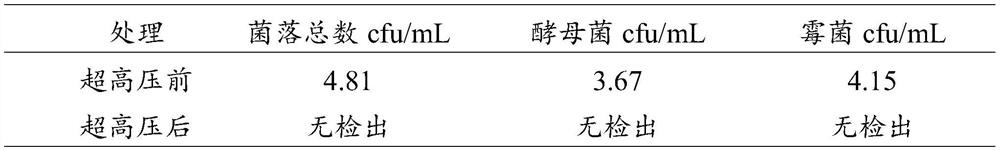

[0033] A method for producing NFC fruit juice in combination with tea polyphenols under high pressure, comprising the steps of:

[0034] 1) Select pineapple fruits that are seven or eight mature, free from diseases and insect pests, and of good quality, peeled, cut into small pieces of 2cm×2cm, soak in water containing 0.5% citric acid for 5min, remove and quickly put them in a draining device for 3min Then put it into a fresh-keeping bag, place it at 6°C for 6 hours, take it out and thaw it at room temperature;

[0035] 2) Put the thawed pulp in a juice extractor to squeeze the juice, add 100mg of pectinase and cellulase mixed enzyme preparation for enzymolysis of the obtained juice for 3 hours, filter through a 200 mesh screen, add 0.2% (in volume percentage of pineapple juice) Glucose or citric acid), the sugar content is adjusted to be 12 ° Bx, and the acidity is 0.8% (in citric acid) to stand still, and the centrifugal 10min is obtained at 5000rpm / min to obtain clear pine...

Embodiment 2

[0045]1) Select pineapple fruits that are seven or eight mature, free from diseases and insect pests, and of good quality, peeled, cut into small pieces of 2cm×2cm, soak in water containing 1% citric acid for 10min, remove and quickly put them in a draining device and let them stand Put it in a fresh-keeping bag after 5 minutes, refrigerate it at 8°C for 8 hours, take it out and thaw it at room temperature;

[0046] 2) Put the thawed pulp in a juice extractor to squeeze the juice, add 300 mg of pectinase and cellulase mixed enzyme preparation to the obtained juice, enzymolyze it for 5 hours, filter it through a 200-mesh sieve, add 0.6% (in the volume of pineapple juice) Percentage) glucose or citric acid, adjust sugar content to be 12 ° Bx, acidity is 0.8% (in citric acid, in volume percent of pineapple juice), 6000rpm / min centrifugal 10min, obtain pineapple clear juice;

[0047] 3) Put the clear pineapple juice in a vacuum degasser for degassing treatment, the juice will be s...

Embodiment 3

[0054] 1) Select pineapple fruits that are seven or eight mature, free from diseases and insect pests, and of good quality, peeled, cut into small pieces of 2cm×2cm, soak in water containing 1% citric acid for 6 minutes, remove and quickly put them in a draining device and let them stand After 4 minutes, put it in a fresh-keeping bag, refrigerate it at 7°C for 7 hours, take it out and thaw it at room temperature;

[0055] 2) Put the thawed pulp in a juice extractor to squeeze the juice, add 500 mg of pectinase and cellulase mixed enzyme preparation to the obtained juice, enzymolyze it for 4 hours, filter it through a 200-mesh sieve, add 1% (in the volume of pineapple juice) Percentage) glucose or citric acid, adjust the sugar content to be 12 ° Bx, and the acidity is 0.8% (acidity is 0.8% (in citric acid, in the volume percentage of pineapple juice), stand still, centrifuge at 5000rpm / min for 10min , to obtain clear pineapple juice;

[0056] 3) Put the clear pineapple juice i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com