A Composite Curved Bevel Gear Scraping Tool

A composite material and arc-shaped tooth technology, which is applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve the problems of high cost and poor heat dissipation, and achieve easy disassembly and improved heat dissipation effect, closely connected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

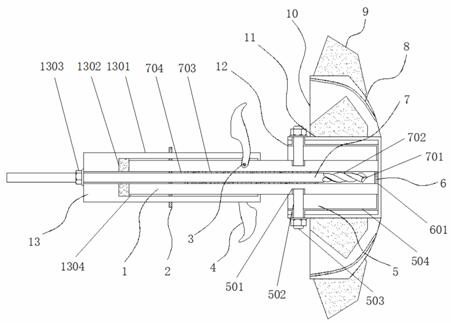

[0035] Example 1: See Figure 1-6 , a composite material arc-shaped bevel gear scraping tool, including a hollow handle 1 and a push rod 2, the top and bottom ends of the hollow handle 1 are respectively provided with a push rod 2, the top end of the hollow handle 1 and the bottom end The other ends are respectively provided with heat dissipation blades 4, and fixed screws 3 are fixedly connected between the hollow handle 1 and the heat dissipation blades 4, and the inside of the hollow handle 1 is provided with a grinding structure 7, and the outside of one side of the hollow handle 1 is provided with an anti-shock structure 13. A cutter body 10 is provided on the outside of the other side of the hollow handle 1, and a disassembly structure 5 is provided between the cutter body 10 and the other side of the hollow handle 1, and an anti-dust chip is provided on the other side of the hollow handle 1. Structure 6, the interior of the cutter body 10 is provided with a heat dissipa...

Embodiment 2

[0040] Embodiment 2: The assembly and disassembly structure 5 is composed of a slot 501, an insertion rod 502, a mounting nut 503 and a bump 504. The slot 501 is arranged inside the hollow handle 1, and the insertion rod 502 vertically penetrates the installation groove 12 and is plugged in Inside the slot 501, a mounting nut 503 is fixedly connected between the insert rod 502 and the cutter body 10, and the bump 504 is welded and fixed around the other side of the hollow handle 1;

[0041] The section of the bump 504 is in the shape of a "cross", and the insertion rod 502 is embedded in the installation groove 12;

[0042] Specifically, such as figure 1 and Figure 5 As shown, when changing the cutter body 10 regularly or scraping gears of different specifications, it is necessary to remove the cutter body 10 from the hollow handle 1, remove the mounting nut 503, pull out the insert rod 502 from the slot 501, and then insert the The cutter body 10 can be disassembled by tak...

Embodiment 3

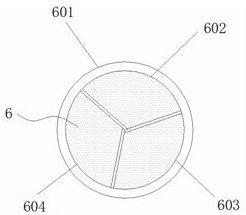

[0043] Embodiment 3: The anti-chip structure 6 is composed of a gasket 601, a first rubber sheet 602, a second rubber sheet 603 and a third rubber sheet 604. The gasket 601 is fixedly connected to the other side inside the hollow cavity 11, and the inner ring of the gasket 601 A first rubber sheet 602, a second rubber sheet 603 and a third rubber sheet 604 are distributed, and the first rubber sheet 602, the second rubber sheet 603 and the third rubber sheet 604 have the same size;

[0044] The first rubber sheet 602, the second rubber sheet 603 and the third rubber sheet 604 are fan-shaped;

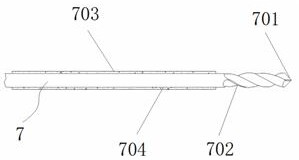

[0045] Specifically, such as figure 1 , figure 2 and Figure 4 As shown, the first rubber sheet 602, the second rubber sheet 603 and the third rubber sheet 604 form a shield for the inner notch of the hollow tool handle 1. When the drill rod 704 is stretched out, the drill bit 702 grinds the blind hole of the gear and other parts At the same time, as the drill rod 704 is pushed out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com