Porcelain insulators glued dry ash glue and its preparation method and application

A pillar porcelain insulator and adhesive technology, applied in the field of pillar porcelain insulators, can solve the problems of no delamination, high early strength and low strength of the test strip section, and achieve the effects of high glue installation efficiency, high early strength and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

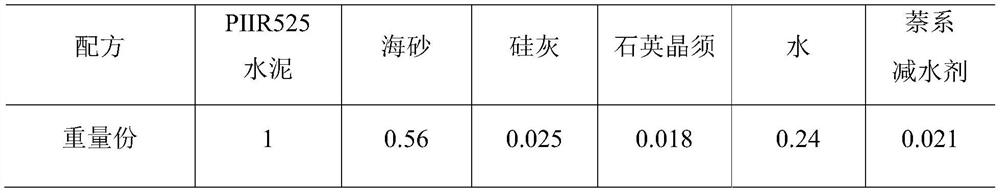

[0033] Table 1 The formula for preparing dry ash cement

[0034]

[0035] (1) Preparation of dry ash binder

[0036] First, prepare the water-reducing agent solution 48 hours in advance according to the proportion of 23.1wt%; then weigh the cement, sea sand, silica fume, water, quartz whiskers and water-reducing agent solution in proportion; pour the sea sand and quartz whiskers into the hourglass ;Pour the water into the mixing bucket, then pour the cement and silica fume, turn on the stirring button, and stir at a speed of 300rpm, after 120s of mixing time; the sea sand automatically flows into the rotating mixing bucket at a constant speed, and stirs at a speed of 300rpm 120s; stop the mixer, pour in the water-reducing agent solution, and use a scraper to scrape off the cement or sea sand that has not been stirred by the mixing blades and the barrel wall; restart the mixer after 60s, and quickly stir at a speed of 1300rpm for 120s, then at a speed of 100rpm Stir slowly ...

Embodiment 2

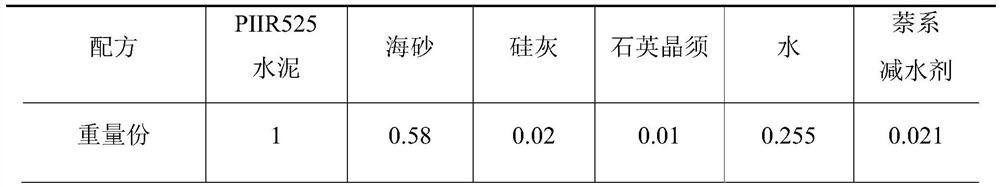

[0042] Table 2 The formula for preparing dry ash cement

[0043]

[0044] (1) Preparation of dry ash binder

[0045] First, prepare the water reducing agent solution 48 hours in advance according to the proportion of 23.1wt%; then weigh the cement, sea sand, silica fume, quartz whiskers, water and water reducing agent in proportion; mix the sea sand and quartz whiskers and pour them into the Hourglass; pour the water into the mixing bucket, then pour the cement and silica fume, turn on the mixing button, and stir at a speed of 350 rpm, and stop after the mixing time is 180 s; after restarting, the sea sand and quartz fibers flow into the rotating mixing bucket at a constant speed, Stir at 350rpm for 150s; stop the mixer, pour in the water-reducing agent solution, and use a scraper to scrape off the cement or sea sand that has not been stirred by the stirring blades and the barrel wall; restart the mixer after 75s, and firstly stir at 1400rpm for 130s, Stir at a slow speed ...

Embodiment 3

[0051] Table 3 The formula for preparing dry ash cement

[0052]

[0053] (1) Preparation of dry ash binder

[0054] First, prepare the water reducing agent solution 48 hours in advance according to the proportion of 23.1wt%; then weigh the cement, artificial sand, silica fume, water, mullite whiskers and water reducing agent solution in proportion; mix the artificial sand and mullite crystal After mixing, pour it into the hourglass; pour the water into the mixing bucket, then pour the cement and silica fume, turn on the stirring button, stir at 280rpm, and stop after the stirring time is 220s; artificial sand and aluminum silicate fiber after restarting Pour it into the rotating mixing bucket at a constant speed, and stir at 300rpm for 100s; stop the mixer, pour in the water reducing agent solution, and use a scraper to scrape off the cement or artificial sand that has not been stirred by the mixing blades and the bucket wall; restart the mixer after 70s, first Stir quickly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com