A kind of melamine resin and its preparation method and application

A melamine and resin technology, applied in the field of melamine resin and its preparation, can solve the problems of reducing formaldehyde content, high cost, and reduced application performance, and achieve the effects of reducing formaldehyde consumption, increasing molecular weight, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

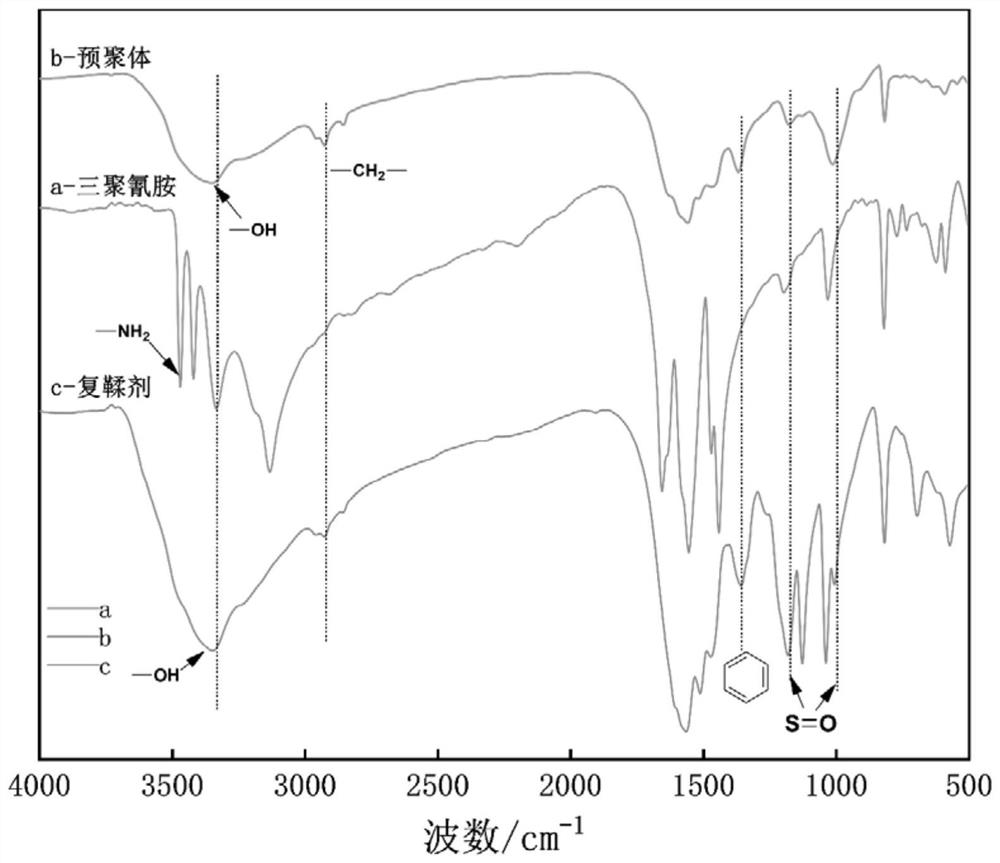

Method used

Image

Examples

Embodiment 1

[0056] The preparation method of the melamine resin provided by the present embodiment may further comprise the steps:

[0057] (1) Weigh 50g of melamine and 20g of paraformaldehyde in a three-necked flask, add 100g of water, stir evenly, then raise the temperature to 60°C, and continue stirring for 40min, during which the pH of the system is constantly adjusted to 8 to obtain a methylol monomer solution;

[0058] (2) Take 81g p-aminobenzenesulfonic acid and dissolve it in 120g water, adjust its pH to 6 to obtain a sulfonic acid compound solution, then add the methylol monomer solution dropwise in the sulfonic acid compound solution, and continue stirring 60min, obtain prepolymer solution;

[0059] (3) Weighing 15 g of glycerol triglycidyl ether was added into the prepolymer solution, and the stirring was continued for 120 min to obtain a melamine resin.

Embodiment 2

[0061] The preparation method of the melamine resin provided by the present embodiment may further comprise the steps:

[0062] (1) Weigh 80g of melamine and 55g of formaldehyde solution into a three-necked flask, add 100g of water, stir evenly, then raise the temperature to 65°C, and continue stirring for 60min, during which the pH of the system is constantly adjusted to 8.3 to obtain a methylol monomer solution ;

[0063] (2) Take by weighing 220g sodium p-aminobenzenesulfonate and dissolve it in 230g water, adjust its pH to 5.7 to obtain a sulfonic acid compound solution, then add the methylol monomer solution dropwise in the sulfonic acid compound solution, continue Stir for 45min to obtain a prepolymer solution;

[0064] (3) Weigh 14g of 4-(2,3-epoxypropyloxy)-N,N-bis(2,3-epoxypropyl)aniline into the prepolymer solution, and continue stirring for 160min to obtain Melamine resin.

Embodiment 3

[0066] The preparation method of the melamine resin provided by the present embodiment may further comprise the steps:

[0067] (1) Weigh 120g of melamine and 100g of paraformaldehyde in a three-necked flask, add 100g of water, stir evenly, then raise the temperature to 76°C, and continue stirring for 100min, during which the pH of the system is constantly adjusted to 8.8 to obtain a methylol monomer solution;

[0068] (2) Take 400g sodium p-aminobenzenesulfonate and dissolve it in 450g water, adjust its pH to 5.0 to obtain a sulfonic acid compound solution, then add the methylol monomer solution dropwise in the sulfonic acid compound solution, continue Stir for 30min to obtain a prepolymer solution;

[0069] (3) Take 62g of epoxidized soybean oil and add it into the prepolymer solution, and continue stirring for 180min to obtain a melamine resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com