Antiskid powder coating material, preparation method and spraying process thereof

A powder coating, anti-skid technology, applied in powder coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of coating anti-skid performance failure, reduce friction coefficient and other problems, achieve excellent anti-skid performance, increase roughness, The effect of excellent anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

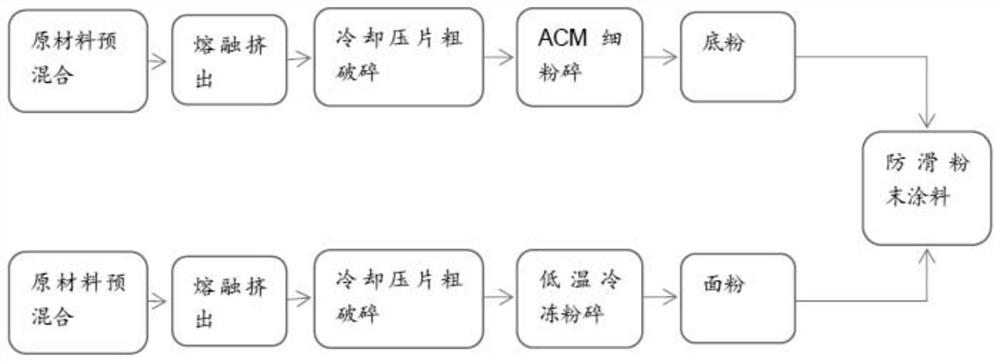

[0038] Such as figure 1 Shown, be the preparation process route of anti-skid powder coating of the present invention; Among the present invention, the preparation method of anti-skid powder coating comprises the steps:

[0039] (1) Weigh the base powder according to the formula percentage to take the raw materials; wait until the temperature of the twin-screw extruder reaches the preset first temperature value, carry out melt extrusion, cooling and pressing, coarse crushing, ACM milling, and classification to obtain an average particle size of 25 - 45μm primer powder;

[0040] (2) Weigh the flour according to the formula percentage and take the raw materials, wait for the single-screw extruder to heat up to the preset second temperature value, perform melt extrusion, cooling and pressing, and water-cooled coarse crushing; perform ACM at the preset third temperature value Grinding and classifying to obtain flour powder with an average particle size of 15-20 μm.

[0041] As a ...

specific Embodiment 1

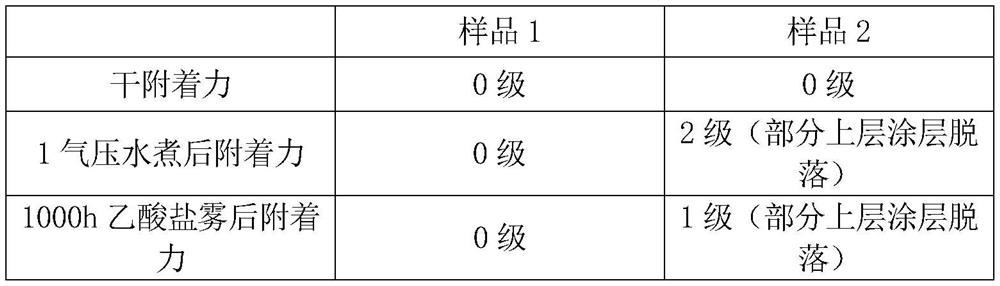

[0048] In the present embodiment, prepare the sample powder of two kinds of antiskid powder coatings, wherein:

[0049] Sample powder 1: The base powder is composed of the following raw materials by weight percentage:

[0050] Epoxy resin: 55%

[0051] Curing agent: 5%

[0052] Modified TPU resin: 15%

[0053] Sanding agent: 0.7%

[0054] Benzoin: 0.2%

[0055] Pigment: 10%

[0056] Filler 14.1%;

[0057] Flour is composed of the following raw materials by weight percentage:

[0058] TPU resin: 75%;

[0059] Nano silica: 0.75%;

[0060] Water: 3.0%;

[0061] Pigment: 12%;

[0062] Filler: 9.25%.

[0063] Sample powder 2: The base powder is composed of the following raw materials by weight percentage:

[0064] Epoxy resin: 55%

[0065] Curing agent: 5%

[0066] Modified TPU resin: 15%

[0067] Sanding agent: 0.7%

[0068] Benzoin: 0.2%

[0069] Pigment: 10%

[0070] Filler 29.1%;

[0071] Flour is composed of the following raw materials by weight percentage:

...

specific Embodiment 2

[0094] In the present embodiment, prepare a kind of sample powder of antiskid powder coating,

[0095] Sample powder 3: The base powder is composed of the following raw materials by weight percentage:

[0096] Epoxy resin: 55%

[0097] Curing agent: 5%

[0098] Modified TPU resin: 15%

[0099] Sanding agent: 0.7%

[0100] Benzoin: 0.2%

[0101] Pigment: 10%

[0102] Filler: 14.1%;

[0103] Flour is composed of the following raw materials by weight percentage:

[0104] TPU resin: 75%;

[0105] Nano silica: 0.75%;

[0106] Pigment: 12%;

[0107] Filler: 12.25%.

[0108] In the present embodiment, the preparation process of antiskid powder coating is as follows:

[0109] 1) The base powder of sample powder 3 was weighed according to the formula percentage, and the raw materials were weighed. After the temperature of the twin-screw extruder was raised to 108°C, melt extrusion, cooling and pressing, coarse crushing, ACM grinding and classification were carried out to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com