Modification method of wheat aleurone layer powder and product thereof

A technology of wheat aleurone layer and modification, which is applied in the direction of food ingredients as pH modifiers, baked foods, food ingredients, etc., and can solve the problem of increasing the hardness and tensile resistance of noodles, deepening the color, and the hardness of pasta and bread increase and other problems, to achieve the effect of increasing content and strong processing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment relates to a preparation method of modified aleurone layer powder, comprising the following steps:

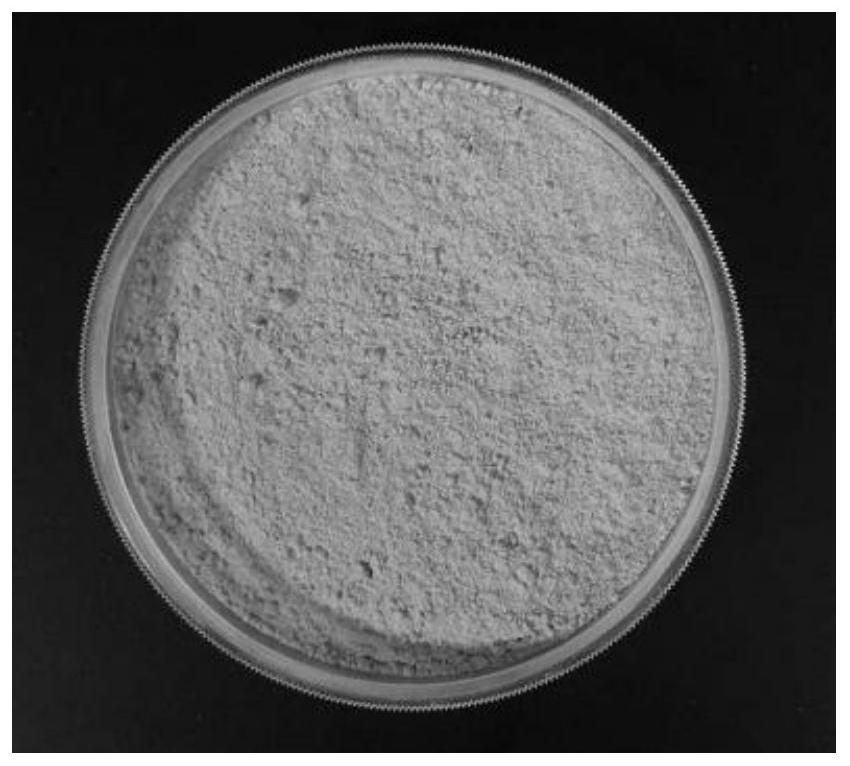

[0038] 1) preparation concentration is the citric acid aqueous solution of 2% (w / w), with 400g aleurone (its state is as figure 1 ) into 1200g of drinking water, then stirred at a constant speed of 180rpm for 1h. Then, 10000rpm high-speed homogenization treatment for 0.3h;

[0039] 2) Add an appropriate amount of calcium hydroxide in the solution, and stir at a constant speed so that the pH value of the solution is 6.5 (such as figure 2 ).

[0040] This embodiment also relates to a method for preparing dough, comprising the steps of:

[0041] 1600g flour and 40g dry yeast are added in the above-mentioned prepared aleurone solution, rub repeatedly to form aleurone dough (such as image 3 ). Finally, the dough was fermented at a temperature of 30°C and a humidity of 80% for 60 minutes to obtain a fermented aleurone dough. The bread that obtains after...

Embodiment 2

[0043] This embodiment relates to a preparation method of modified aleurone layer powder, comprising the following steps:

[0044]1) Prepare an aqueous citric acid solution with a concentration of 2% (w / w), add 400g of aleurone powder into 1200g of drinking water, heat to 70°C, and then stir at a constant speed of 180rpm for 1h. Then, 10000rpm high-speed homogenization treatment for 0.3h.

[0045] 2) Add transglutaminase (activity: 80 U / g) which is 1% of the aleurone mass into the aleurone solution, stir at a constant speed, and heat at 35° C. for 3 hours.

[0046] This embodiment also relates to a method for preparing dough, comprising the steps of:

[0047] Add 1600g of flour and 40g of dry yeast into the aleurone solution prepared above, and knead repeatedly to form aleurone dough. Finally, the dough was fermented at a temperature of 30°C and a humidity of 80% for 60 minutes to obtain a fermented aleurone dough.

Embodiment 3

[0049] This embodiment relates to a preparation method of modified aleurone layer powder, comprising the following steps:

[0050] 1) Prepare an aqueous citric acid solution with a concentration of 2% (w / w), add 400g of aleurone powder into 1200g of drinking water, heat to 70°C, and then stir at a constant speed of 180rpm for 1h. Then, 10000rpm high-speed homogenization treatment for 0.3h;

[0051] 2) An appropriate amount of calcium hydroxide is added to the solution, and stirred at a constant speed so that the pH of the solution is 6.5.

[0052] 3) Add transglutaminase (with an activity of 80 U / g) of 1% by mass of the aleurone powder into the aleurone solution, stir at a constant speed, and heat at 35° C. for 3 hours.

[0053] This embodiment also relates to a method for preparing dough, comprising the steps of:

[0054] Add 1600g of flour and 40g of dry yeast into the aleurone solution prepared above, and knead repeatedly to form aleurone dough. Finally, the dough was fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com