Harmless treatment method of arsenic-containing waste reagent

A technology of harmless treatment and reagents, which is applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of low arsenic content and inability to dispose of arsenic trioxide, etc., achieve simple steps, reduce toxicity and migration, and reduce pollution and harm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

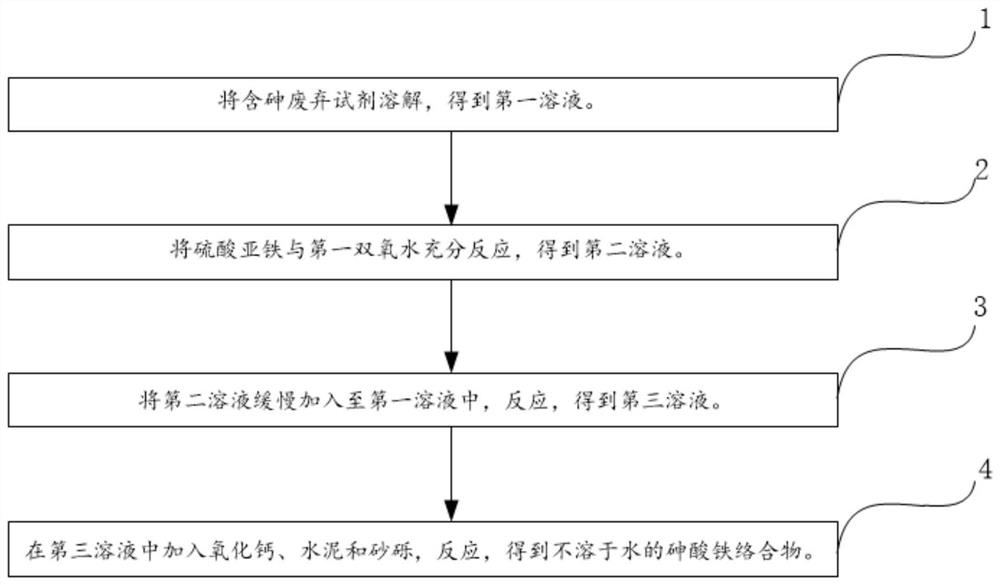

[0030] A kind of harmless treatment method of waste reagent containing arsenic, see figure 1 , the method includes the following steps:

[0031] Step (1): dissolving the waste reagent containing arsenic to obtain a first solution.

[0032] Step (2): fully reacting ferrous sulfate with the first hydrogen peroxide to obtain a second solution.

[0033] Step (3): Slowly add the second solution to the first solution and react to obtain the third solution;

[0034] Step (4): Calcium oxide, cement and gravel are added to the third solution for reaction to obtain a water-insoluble iron arsenate complex.

Embodiment 2

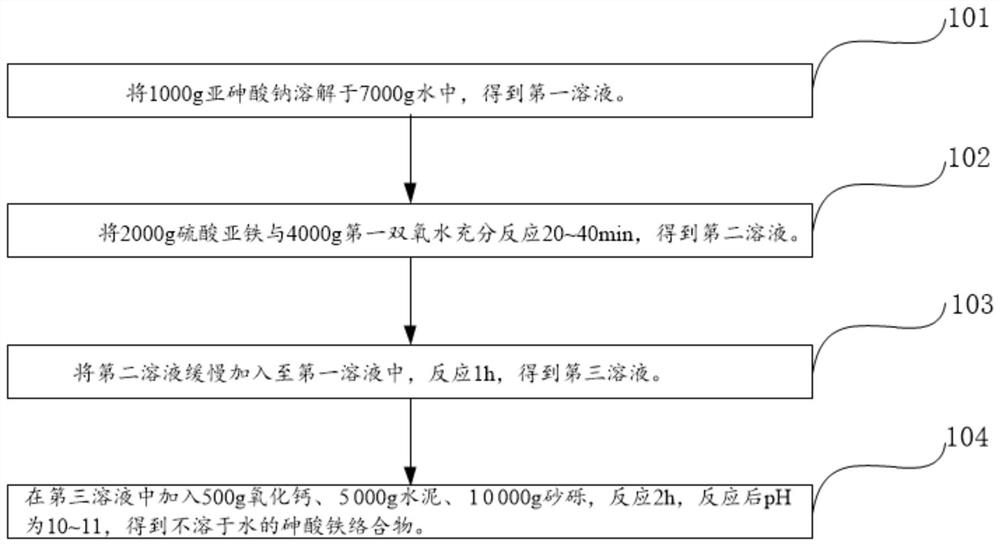

[0036] combine figure 2 to the above figure 1 A harmless treatment method for arsenic-containing waste reagents shown in the article is discussed in detail, see figure 2 , the method includes the following steps:

[0037] Step (101): dissolving 1000 g of sodium arsenite in 7000 g of water to obtain a first solution.

[0038] Step (102): Fully react 2000g of ferrous sulfate with 4000g of first hydrogen peroxide for 20-40min to obtain a second solution.

[0039] Step (103): Slowly add the second solution to the first solution, and react for 1 hour to obtain a third solution.

[0040] Step (104): Add 500g of calcium oxide, 5000g of cement, and 10000g of gravel into the third solution, and react for 2 hours. After the reaction, the pH is 10-11 to obtain a water-insoluble iron arsenate complex.

[0041] It should be noted that according to the above method, the staff conducted three sets of tests, obtained three sets of sodium arsenite-treated samples, and tested the three se...

Embodiment 3

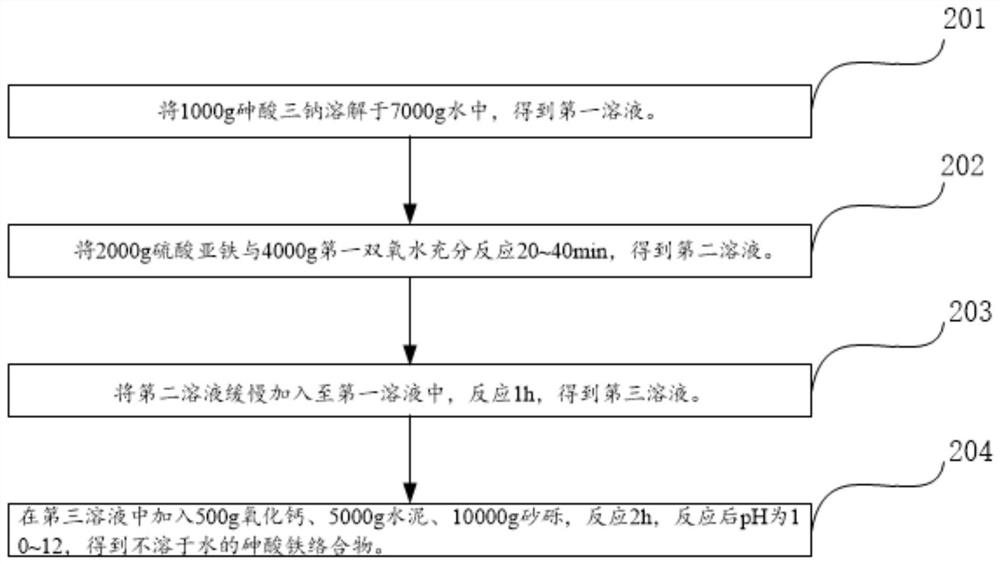

[0046] combine image 3 to the above figure 1 A harmless treatment method for arsenic-containing waste reagents shown in the article is discussed in detail, see image 3 , the method includes the following steps:

[0047] Step (201): dissolving 1000 g of trisodium arsenate in 7000 g of water to obtain a first solution.

[0048] Step (202): Fully react 2000g ferrous sulfate with 4000g first hydrogen peroxide for 20-40min to obtain a second solution.

[0049] Step (203): Slowly add the second solution to the first solution, and react for 1 hour to obtain a third solution.

[0050] Step (204): Add 500g of calcium oxide, 5000g of cement, and 10000g of gravel into the third solution, and react for 2 hours. After the reaction, the pH is 10-12 to obtain a water-insoluble iron arsenate complex.

[0051] It should be noted that according to the above method, the staff conducted three sets of tests, obtained three sets of trisodium arsenate treated samples, and tested the three sets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com