Preparation device and method of PCL material for 3D printing

A 3D printing and preparation device technology, which is applied in the direction of manufacturing auxiliary devices, separation methods, chemical instruments and methods, etc., can solve the problems of low requirements for 3D printing equipment, low melt strength, and difficult molding, etc., and achieve a simple and easy preparation method Good printing performance and low printing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one: be used for the preparation method of 3D printing PCL material, operate and produce according to the following steps:

[0032] Step 1: First add 80g of polycaprolactone, 20g of starch, 44681g of chain extender, 5g of lubricant calcium stearate, 0.5g of antibacterial agent, 5g of silicon dioxide, and 5g of polyethylene glycol into the sealed bag, and manually Shake the material well, weigh the material according to the formula ratio, and at the same time, the formula seriously affects the melting point of PCL to determine the 3D printing performance of the finished PCL. Bake for several hours to increase the viscosity of PCL and make it easier to mix evenly;

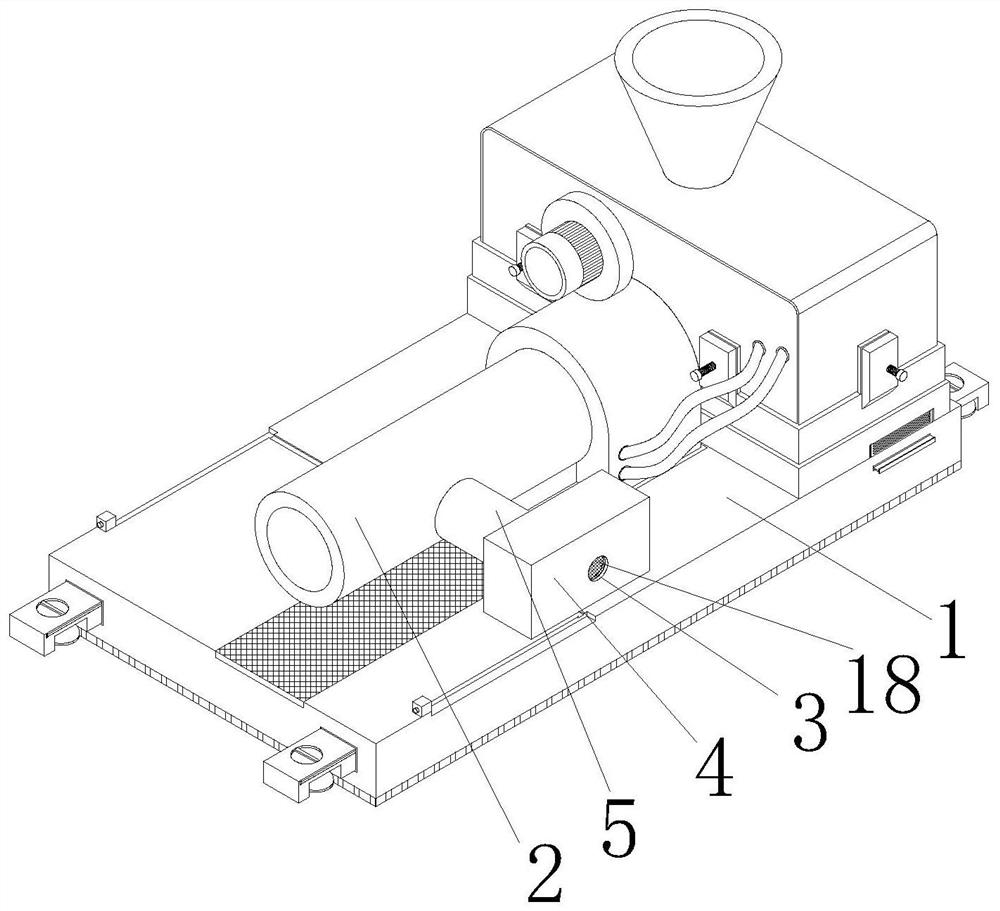

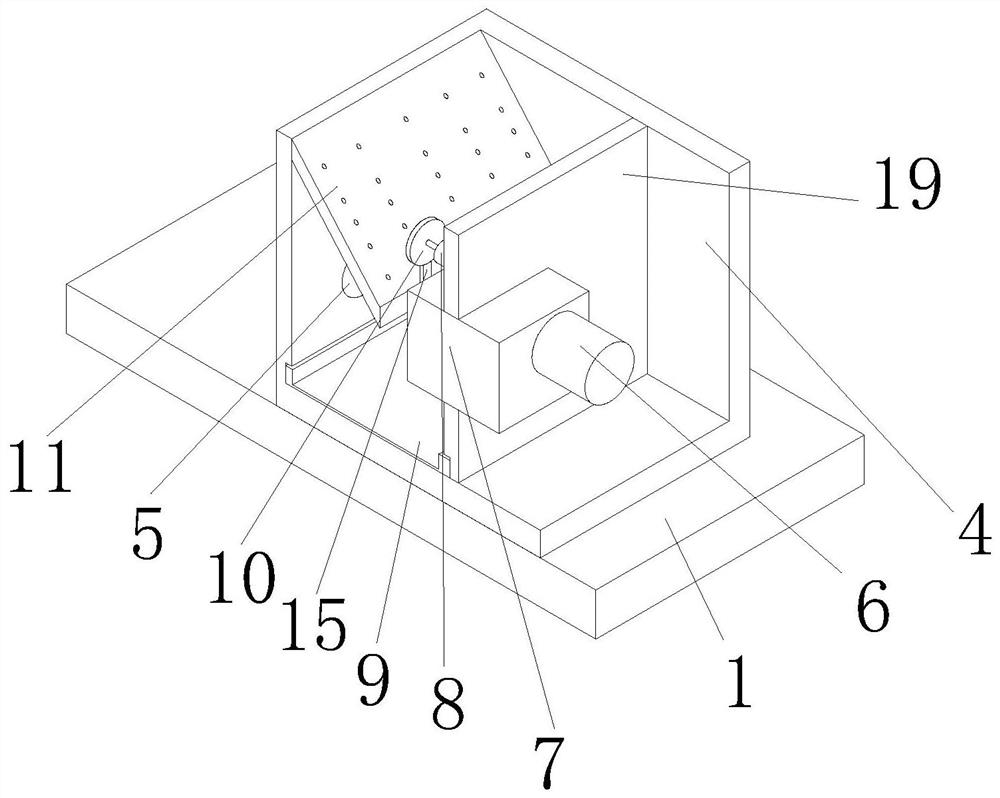

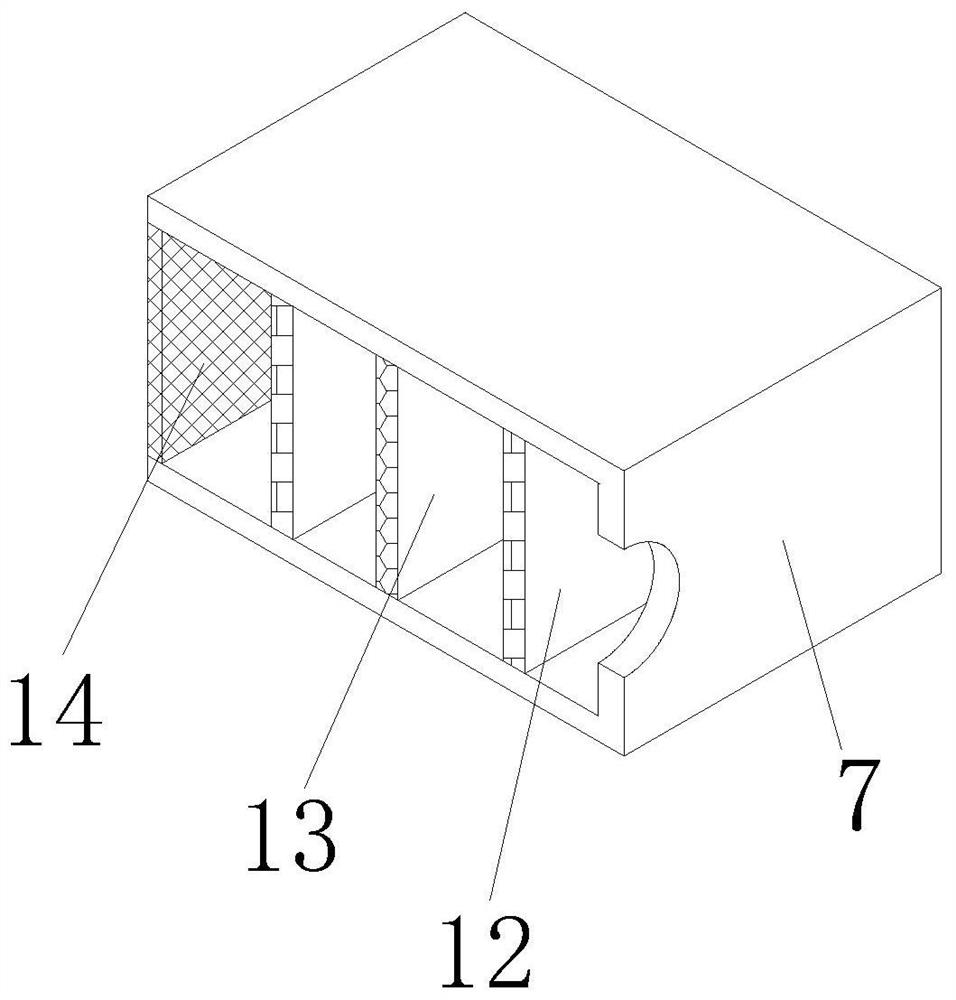

[0033]The second step: add a part of the blended materials to the twin-screw extruder for car washing, clean the twin-screw extruder, add the remaining materials for twin-screw blending, and extrude the wire rod extruded by the twin-screw extruder Granulate through a granulator, extrusion temperatu...

Embodiment 2

[0037] Embodiment two: be used for the preparation method of 3D printing PCL material, operate and produce according to the following steps:

[0038] Step 1: First add 95g of polycaprolactone, 5g of starch, 44681g of chain extender, 5g of lubricant calcium stearate, 0.5g of antibacterial agent, 3g of silicon dioxide, and 15g of polyethylene glycol into the sealed bag, and manually Shake the material well, and weigh the material according to the formula ratio. The formula seriously affects the melting point of PCL to determine the 3D printing performance of the finished PCL. At the same time, put the material in a sealed bag at room temperature, shake it well, and put it in the oven Several hours make the viscosity of PCL rise so that it is easier to mix evenly;

[0039] The second step: add a part of the blended materials to the twin-screw extruder for car washing, clean the twin-screw extruder, add the remaining materials for twin-screw blending, and extrude the wire rod extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com