Float glass production line sealing box

A float glass, sealed box technology, applied in the direction of containers, packaging items, special packaging items, etc., can solve the problems of easy stacking, flat glass products collision and fragmentation, easy horizontal sliding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

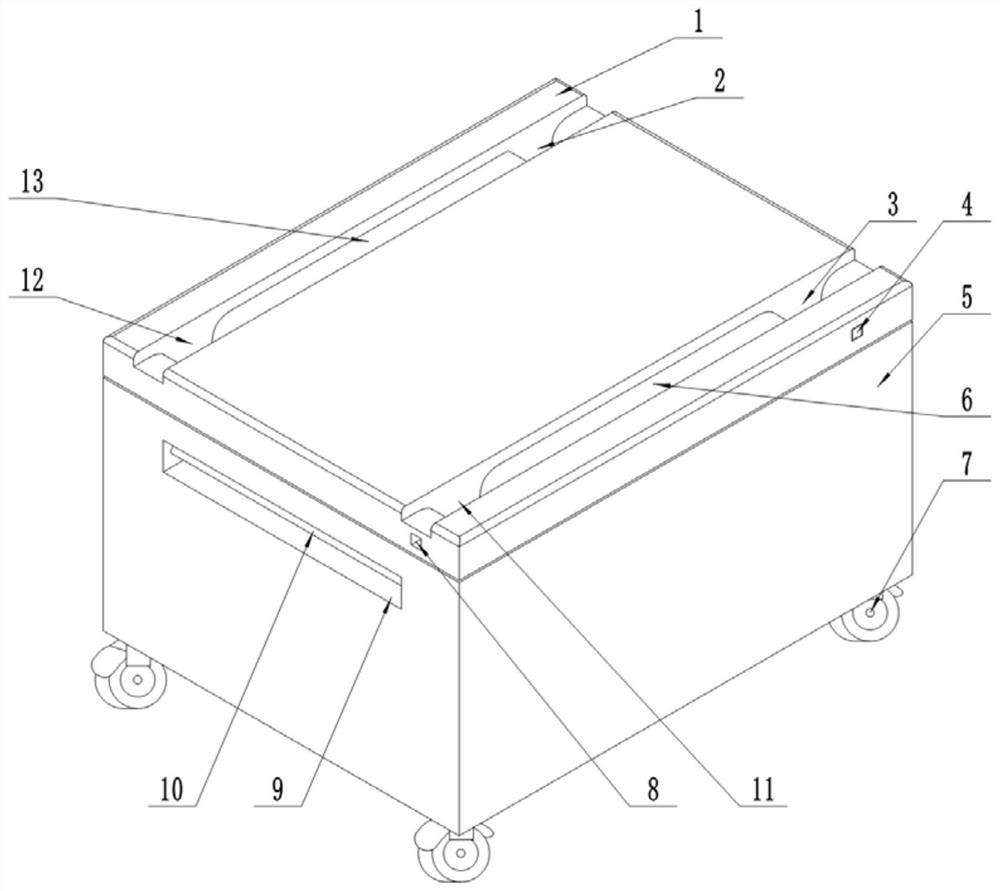

[0032] A kind of sealing box of float glass production line, basically as figure 1 , figure 2 Shown: including the sealed box body, foam board and other materials used to buffer and protect the glass are arranged on the inner side wall of the sealed box body, and the internal structure of the sealed box body can adopt the existing glass sealed box structure, so this The embodiment does not repeat too much. The four corners of the bottom surface of the sealed box body are fixed with four universal wheels 7. In this embodiment, the universal wheels 7 are common universal wheels 7, and the casters of the universal wheels 7 are made of soft material, which is convenient for short distances. Shock absorption for transport.

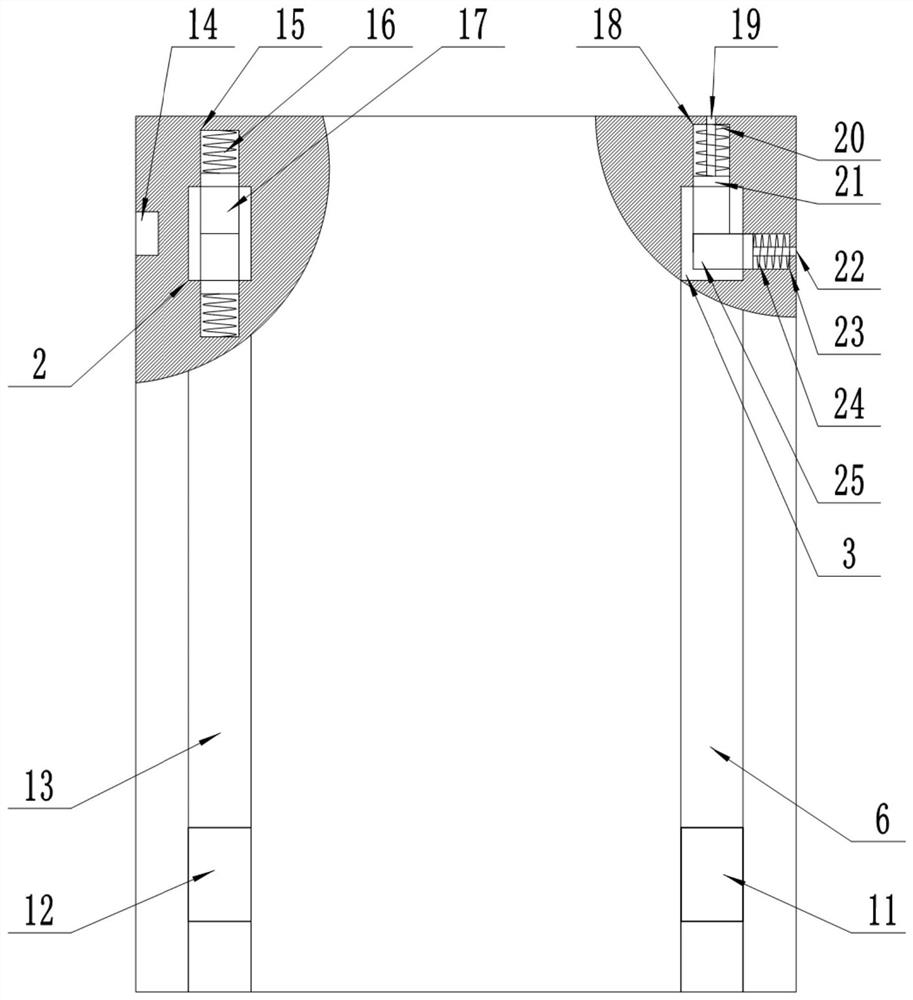

[0033] The sealed box body includes a box body 5 and a box cover 1 that is rotatably connected to the box body 5. The four corners of the box cover 1 are provided with four placement grooves for placing universal wheels 7, and the placement grooves include t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com