Preparation method and application of composite flocculant

A composite flocculant and organic flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve problems such as poor oil removal effect, improve flocculation performance and increase positive charge Density, the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

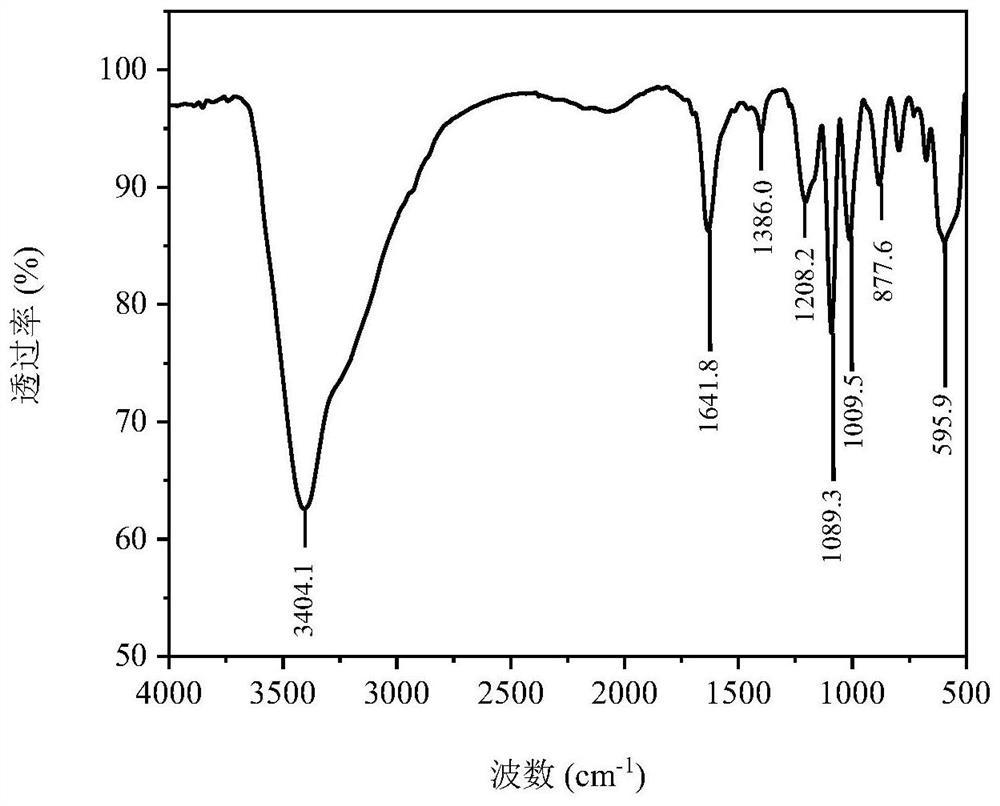

[0033] According to one embodiment of the present invention, a kind of preparation method of composite flocculant is provided, comprising:

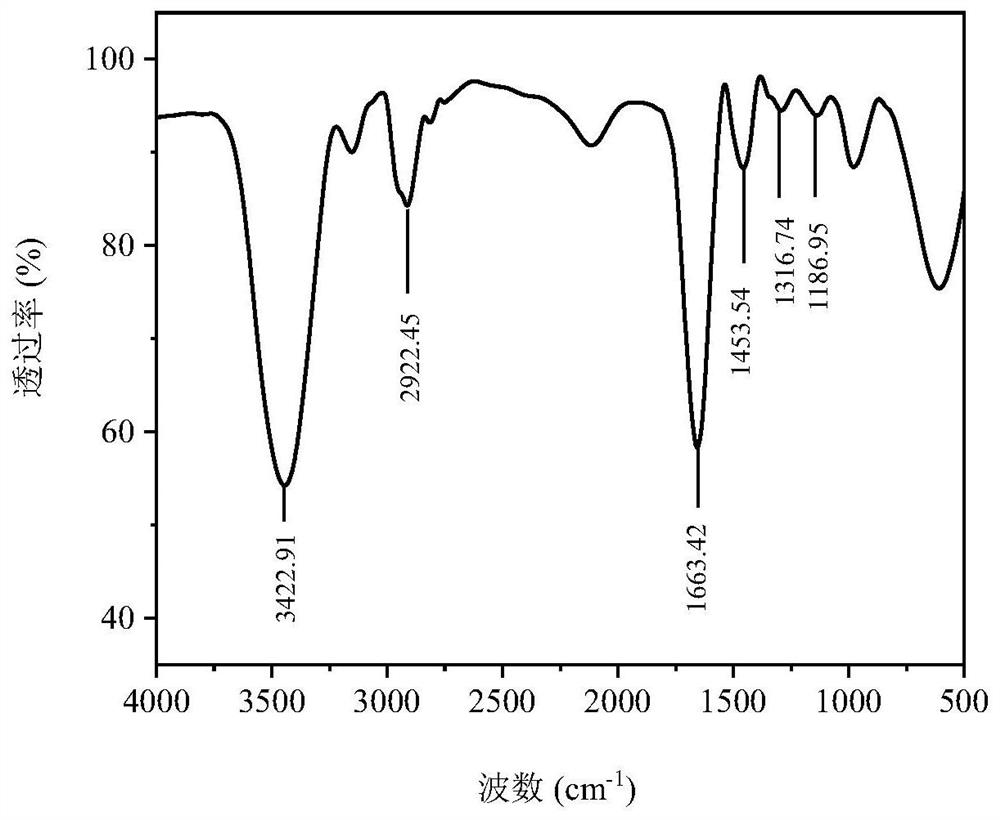

[0034] Polymerized ferric sulfate and organic flocculant are homogeneously compounded to obtain a composite flocculant; among them, polyferric sulfate is obtained by hydrothermal synthesis of ferrous sulfate, and the organic flocculant is made of acrylamide, dimethyl diallyl chloride A polymer formed by the polymerization of ammonium chloride and stearyl methacrylate.

[0035] Further, the preparation method of polymerized ferric sulfate comprises: adding an oxidizing agent to an acidic solution containing ferrous sulfate for oxidation reaction, then adding a strong base to adjust the pH of the reaction system to 6.8-7.2, then performing a stirring reaction, and then transferring the reaction solution to Carry out hydrothermal reaction in a hydrothermal reactor to obtain polyferric sulfate.

[0036] Further, the preparation method of the...

Embodiment 1

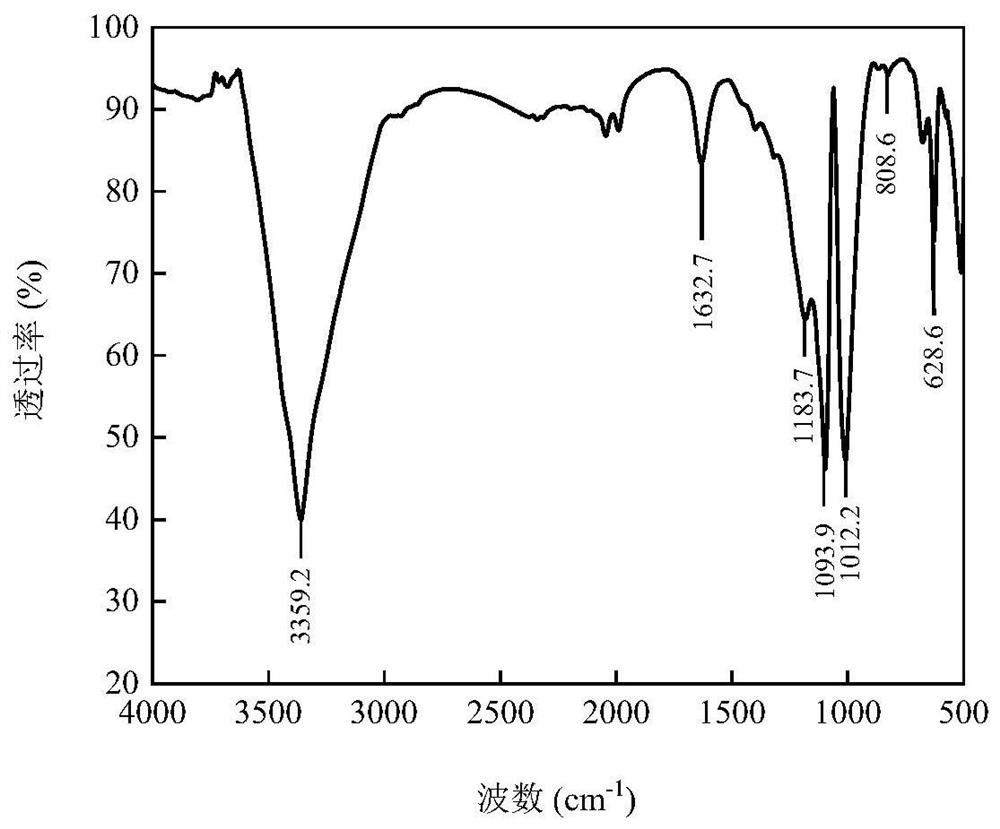

[0043] 1) Preparation of Nano Polymerized Ferric Sulfate (PFS):

[0044] First weigh 27.8 grams of FeSO 4 ·7H 2 O solid particles and dissolved in 300mL of glycerol solution with a mass fraction of 50% (glycerol and water are mixed at a ratio of 1:1), and acidified by adding 10-12mL of concentrated sulfuric acid to control Fe 2+ : SO 4 2- The molar ratio is 1.1 to 1.2, so that the pH value of the solution reaches 1.5, and then the mass fraction is 30% H 2 o 2 , the dosage is 51mL (adding excess H 2 o 2 , to ensure that Fe in solution 2+ is completely oxidized), adding H 2 o 2 Afterwards, the solution was rapidly oxidized to reddish-brown, and then continued to slowly add 0.1mol / L sodium hydroxide solution dropwise under stirring conditions to adjust the pH value of the solution to 7.0, and continued to stir and react in a magnetic stirrer at a constant temperature of 60°C for 120 minutes. , put the reaction solution into a hydrothermal reaction kettle, and conduct a ...

Embodiment 2

[0050] 1) Preparation of Nano Polymerized Ferric Sulfate (PFS):

[0051] First weigh 27.8 grams of FeSO 4 ·7H 2 O solid particles and dissolved in 300mL of glycerol solution with a mass fraction of 50% (glycerol and water are mixed at a ratio of 1:1), and acidified by adding 10-12mL of concentrated sulfuric acid to control Fe 2+ : SO 4 2- The molar ratio is 1.1 to 1.2, so that the pH value of the solution reaches 1.3, and then 30% H by mass fraction is added dropwise in a water bath at a constant temperature of 50°C 2 o 2 , the dosage is 51mL (adding excess H 2 o 2 , to ensure that Fe in solution 2+ is completely oxidized), adding H 2 o 2 Afterwards, the solution was rapidly oxidized to reddish-brown, and then continued to slowly add 0.1mol / L sodium hydroxide solution dropwise under stirring conditions, adjusting the pH value of the solution to 6.8, and continued to stir and react in a magnetic stirrer at a constant temperature of 55°C for 130 minutes. , put the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com