Dispersion method of nano magnesium oxide, nano magnesium oxide expanding agent and application of nano magnesium oxide expanding agent in preparation of expanding cement base material

A technology of nano-magnesium oxide and expansive cement, which is applied in the dispersion of nano-magnesium oxide, the application in the preparation of expansive cement base material, and the field of nano-magnesium oxide expansion agent, which can solve the problem that the expansion performance of magnesia cannot be effectively exerted, and the expansion of cement-based materials Slow development, reduced mechanical properties and other problems, to achieve the effect of improving shrinkage cracking, uniform and stable dispersion, and compensating shrinkage deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

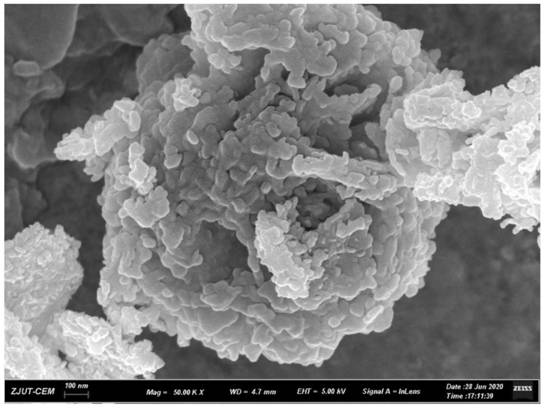

[0051] (1) Dispersion of nano-magnesia: take 3.2g dispersant polycarboxylate superplasticizer (purchased from Jilong Chemical Building Materials Co., Ltd.) in a beaker, add 400g distilled water in the beaker, then get 16.0g nano-magnesia and add it to the beaker; After stirring with a glass rod, the mixed solution was dispersed with a heat-collecting magnetic stirrer (the magnetic stirrer was purchased from Hunan Frontier Technology Co., Ltd., the model is photosynthetic DF-101S), the rotating speed was 600 rpm, the power was 40W, and the stirring time was 5min; Immediately after stirring and dispersing, carry out ultrasonic ice-bath dispersion (ultrasonic disperser is purchased from Hunan Frontier Technology Co., Ltd., FS-750T type), dispersing power is 50W, dispersing time is 5min, and the limit temperature is 35°C. The SEM image of nano-magnesium oxide expansion agent is prepared. Such as figure 1 As shown, the size of nano magnesium oxide is 50nm, and no aggregation occurs...

Embodiment 2

[0056] (1) Dispersion of nano-magnesia: get 4.0g dispersant polycarboxylate superplasticizer (purchased from Jilong Chemical Building Materials Co., Ltd.) in a beaker, add 600g distilled water in the beaker, then get 40g nano-magnesia and add in the beaker; After the glass rod was stirred, the mixed solution was dispersed by a heat-collecting magnetic stirrer (the magnetic stirrer was purchased from Hunan Frontier Technology Co., Ltd., the model is photosynthetic DF-101S), the rotating speed was 800 rpm, the power was 40W, and the stirring time was 10 min; Immediately after dispersion, ultrasonic ice bath dispersion was carried out (ultrasonic disperser was purchased from Hunan Frontier Technology Co., Ltd., FS-750T type), the dispersion power was 50W, the dispersion time was 10min, and the limit temperature was 40°C to prepare the nano-magnesia expansion agent;

[0057] (2) Preparation of expansive concrete: According to JGJ55-2011 "Ordinary Concrete Mixing Design Regulations"...

Embodiment 3

[0062] (1) Dispersion of nano-magnesia: take 2.0g dispersant polycarboxylate superplasticizer (purchased from Jilong Chemical Building Materials Co., Ltd.) in a beaker, add 350g distilled water in the beaker, then take 8.8g nano-magnesia and add it to the beaker; After stirring with a glass rod, the mixed solution was dispersed by a heat-collecting magnetic stirrer (the magnetic stirrer was purchased from Hunan Frontier Technology Co., Ltd., the model is photosynthetic DF-101S), the rotating speed was 900 rpm, the power was 40W, and the stirring time was 5min; Immediately after stirring and dispersing, carry out ultrasonic ice-bath dispersion (ultrasonic disperser is purchased from Hunan Frontier Technology Co., Ltd., FS-750T type), dispersing power is 60W, dispersing time is 8min, and the limit temperature is 40°C to prepare nano-magnesium oxide expansion agent;

[0063] (2) Preparation of expansive cement mortar: According to GB / T17671-1999 "Cement Mortar Strength Test Method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com