High-flexibility and low-shrinkage fiber reinforced cement-based composite material

A fiber-reinforced cement and composite material technology, applied in the field of building materials, can solve problems such as increased risk of cracking, poor synergistic workability, large drying shrinkage of substrates, etc., and achieves high toughness, small crack width, and low drying shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

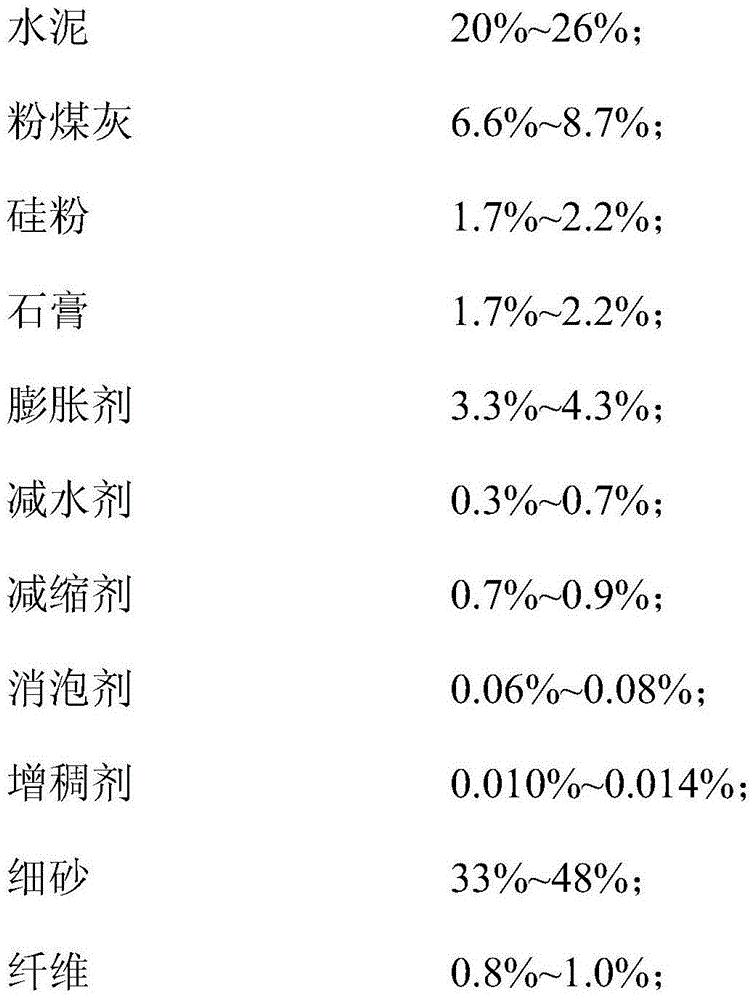

[0040] A fiber-reinforced cement-based composite material with high toughness and low dry shrinkage, which is composed of cement, fly ash, silica fume, gypsum, expansion agent, water reducer, shrinkage reducer, defoamer, thickener, fine sand, fiber and It is mixed with water, of which cement, fly ash, silica fume, gypsum, expansion agent, water reducing agent, shrinkage reducing agent, defoamer, thickener, fine sand and fiber account for 80.5% of the total mass percentage, and water accounts for The mass percentage is 19.5%.

[0041] The cement is rapid-hardening sulfoaluminate cement with a strength grade of 42.5; the fly ash is a low-calcium fly ash of the first grade; the silica fume is micro-silica fume produced by Gansu Sanyuan Silicon Material Co., Ltd.; the gypsum is high-strength building gypsum powder; The expansion agent is a commercially available ZY composite concrete expansion agent; the water reducer is a polycarboxylate high-efficiency water reducer; the shrinka...

Embodiment 2

[0048]A fiber-reinforced cement-based composite material with high toughness and low dry shrinkage, which is composed of cement, fly ash, silica fume, gypsum, expansion agent, water reducer, shrinkage reducer, defoamer, thickener, fine sand, fiber and It is mixed with water, of which cement, fly ash, silica fume, gypsum, expansion agent, water reducing agent, shrinkage reducing agent, defoamer, thickener, fine sand and fiber account for 79% by mass, and water accounts for 79% by mass The percentage is 21%.

[0049] The cement is rapid-hardening sulfoaluminate cement with a strength grade of 42.5; the fly ash is a low-calcium fly ash of the first grade; the silica fume is micro-silica fume produced by Gansu Sanyuan Silicon Material Co., Ltd.; the gypsum is high-strength building gypsum powder; The expansion agent is a commercially available ZY composite concrete expansion agent; the water reducer is a naphthalene-sulfamate composite high-efficiency water reducer; the shrinkage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com