Enhanced ecological foam light soil material and preparation method thereof

A foam lightweight soil, enhanced technology, applied in the direction of botanical equipment and methods, planting substrates, ceramic products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

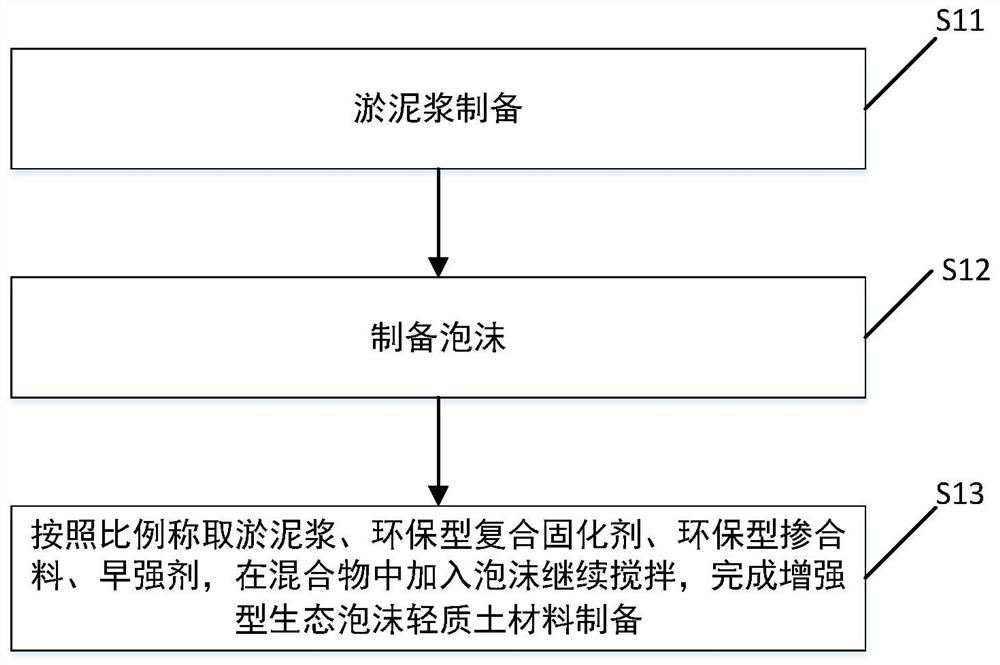

Method used

Image

Examples

Embodiment 1

[0039] The reinforced ecological foam lightweight soil material is configured, and the prepared foam lightweight soil material is shown in Table 1, and is composed of the following components by mass percentage:

[0040] Table 1:

[0041] sludge Foam Environmentally friendly composite curing agent Environmentally friendly additives early strength agent 70 2.5 11.5 15.8 0.2

[0042] It should be noted that the effect of adding a curing agent here is: after adding a curing agent to the sludge, its physical properties will change, and the addition of the curing agent will consume part of the water and organic matter to generate new substances, thereby changing the moisture content of the sludge, liquid plastic It can improve the unconfined compressive strength of the soil, increase its hardness and waterproof effect.

[0043] Solid waste solidification meets the requirements of national standards. After certain treatment, the cured product is waterp...

Embodiment 2

[0049] The enhanced ecological foam lightweight soil material is configured, and the prepared foam lightweight soil material is shown in Table 2, and consists of the following components by mass percentage:

[0050] Table 2:

[0051] sludge Foam Environmentally friendly composite curing agent Environmentally friendly additives early strength agent 75 3 13 8.75 0.25

[0052]It should be noted that the effect of adding a curing agent here is: after adding a curing agent to the sludge, its physical properties will change, and the addition of the curing agent will consume part of the water and organic matter to generate new substances, thereby changing the moisture content of the sludge, liquid plastic It can improve the unconfined compressive strength of the soil, increase its hardness and waterproof effect.

[0053] Solid waste solidification meets the requirements of national standards. After certain treatment, the cured product is waterproof and ...

Embodiment 3

[0059] The enhanced ecological foam lightweight soil material is configured, and the prepared foam lightweight soil material is shown in Table 3, and consists of the following components by mass percentage:

[0060] table 3:

[0061] sludge Foam Environmentally friendly composite curing agent Environmentally friendly additives early strength agent 80 2 11 6.8 0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com