Preparation method of process feed liquid formaldehyde-removing resin

A technology for removing aldehyde resin and material liquid, applied in the field of resin, can solve the problems of high cost of sewage treatment and damaged performance, and achieve the effect of good aldehyde removal ability and economic effect, good preservation degree and good economic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

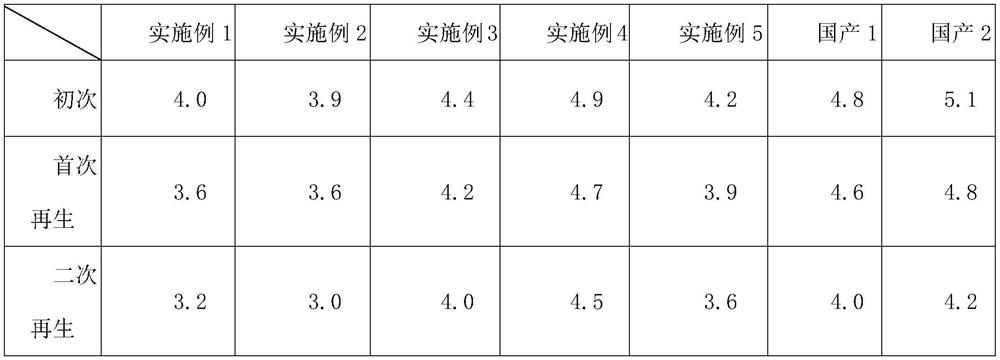

Examples

Embodiment 1

[0020] S1. Prepare 20 parts of pentaerythritol, 4 parts of ricinoleic acid, 6 parts of isopropyl ester, 10 parts of ethanol, 10 parts of maleic anhydride, 2 parts of gelatin, 25 parts of xylene, 1 can of nitrogen and 1 part of anti-aging agent;

[0021] S2, reacting ricinoleic acid, maleic anhydride, phthalic anhydride, gelatin and pentaerythritol, feed nitrogen into it during the reaction, the reaction temperature is controlled at 150 degrees, and the reaction time is controlled at 5 hours to obtain crude alkyd resin;

[0022] S3, dissolving and mixing the crude alkyd resin and xylene, and filtering after mixing and dissolving to obtain a resin solution;

[0023] S4, mixing the resin solution with isopropanol and ethanol, and slowly adding n-butyl acetate and anti-aging agent, the reaction temperature is controlled at 50 degrees, and the reaction time is controlled at 3 hours to obtain a crude product;

[0024] S5. Dilute the crude product with xylene, and control the reactio...

Embodiment 2

[0026] S1. Prepare 20 parts of pentaerythritol, 4 parts of ricinoleic acid, 6 parts of isopropyl ester, 10 parts of ethanol, 10 parts of maleic anhydride, 2 parts of gelatin, 25 parts of xylene, 1 can of nitrogen and 1 part of anti-aging agent;

[0027] S2, reacting ricinoleic acid, maleic anhydride, phthalic anhydride, gelatin and pentaerythritol, feed nitrogen into it during the reaction, the reaction temperature is controlled at 150 degrees, and the reaction time is controlled at 5 hours to obtain crude alkyd resin;

[0028] S3, dissolving and mixing the crude alkyd resin and xylene, and filtering after mixing and dissolving to obtain a resin solution;

[0029] S4, mixing the resin solution with isopropanol and ethanol, and slowly adding n-butyl acetate and anti-aging agent, the reaction temperature is controlled at 250 degrees, and the reaction time is controlled at 3 hours to obtain a crude product;

[0030] S5. Dilute the crude product with xylene, and control the reacti...

Embodiment 3

[0032] S1. Prepare 20 parts of pentaerythritol, 4 parts of ricinoleic acid, 6 parts of isopropyl ester, 10 parts of ethanol, 10 parts of maleic anhydride, 2 parts of gelatin, 25 parts of xylene, 1 can of nitrogen and 1 part of anti-aging agent;

[0033] S2, reacting ricinoleic acid, maleic anhydride, phthalic anhydride, gelatin and pentaerythritol, feed nitrogen into it during the reaction, the reaction temperature is controlled at 250 degrees, and the reaction time is controlled at 5 hours to obtain crude alkyd resin;

[0034] S3, dissolving and mixing the crude alkyd resin and xylene, and filtering after mixing and dissolving to obtain a resin solution;

[0035] S4, mixing the resin solution with isopropanol and ethanol, and slowly adding n-butyl acetate and anti-aging agent, the reaction temperature is controlled at 50 degrees, and the reaction time is controlled at 3 hours to obtain a crude product;

[0036] S5. Dilute the crude product with xylene, and control the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com