Preparation method of heterogeneous lignin/polylactic acid composite material

A composite material and lignin technology, which is applied in the field of preparation of heterogeneous lignin/polylactic acid composite materials, can solve problems such as the inability to strengthen and toughen polylactic acid materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

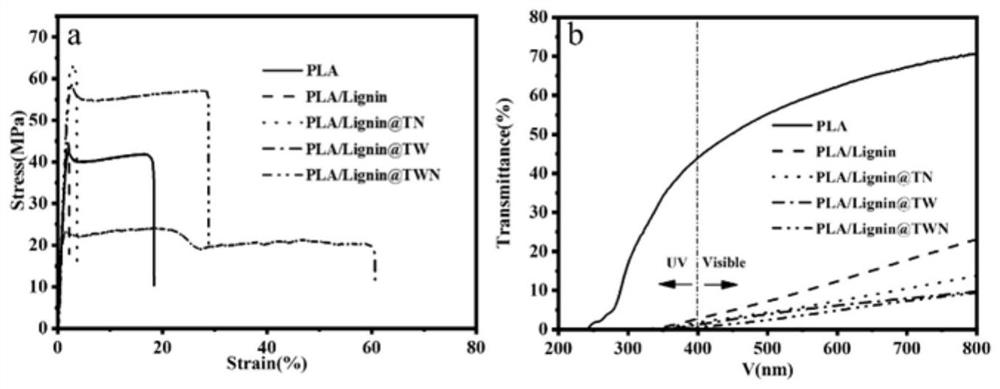

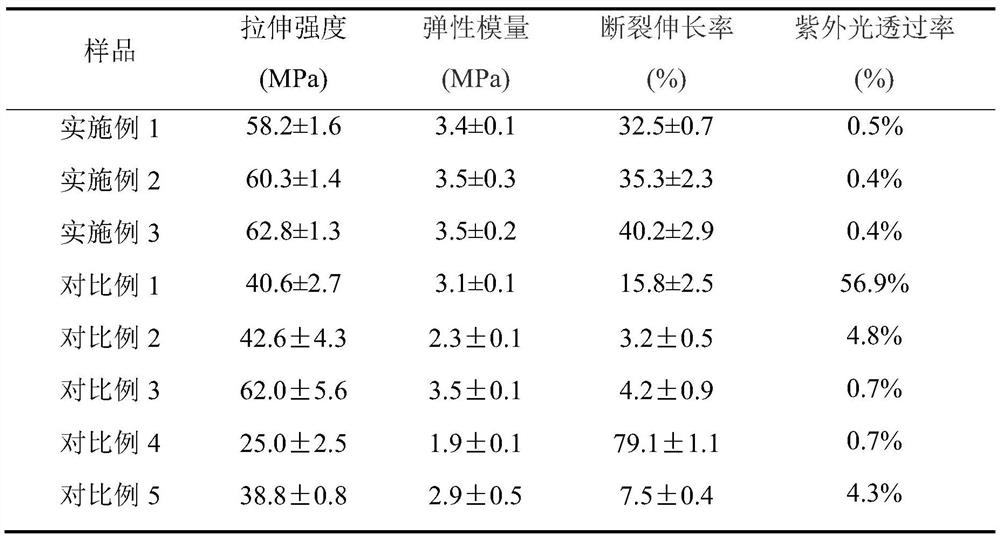

Examples

Embodiment 1

[0040] A preparation method for a heterogeneous lignin / polylactic acid film, comprising the following steps:

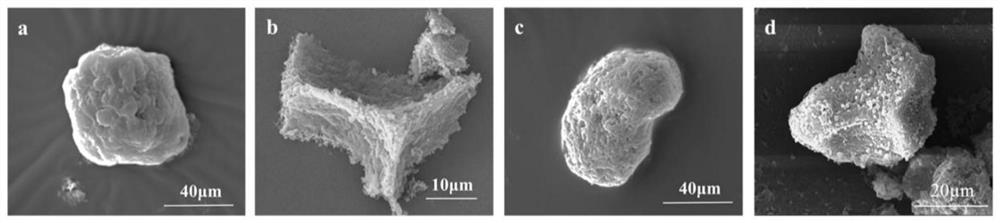

[0041] (1) Preparation of heterogeneous lignin

[0042] First, add 3g of Lignin powder and 10mL of deionized water into a beaker, after stirring, add 0.3g of Span 20, 0.3g of Tween 20, and use an ultrasonic instrument to perform ultrasonic treatment for 10 minutes to ensure that the solution is fully dissolved; then, the completely dissolved The solution was poured into a zirconia ball milling jar equipped with 16 large zirconia ball milling beads with a diameter of 10 mm and 100 small zirconia ball milling beads with a diameter of 6 mm. The speed of the planetary ball mill was set at 480 rpm, and the solution mixture was ball-milled for 24 h, and the milling was interrupted for 30 min every 2 h to prevent overheating. After the ball milling was completed, samples of heterogeneous lignin powder were collected, and the collected samples were freeze-dried for 48 hours ...

Embodiment 2

[0046] A preparation method for a heterogeneous lignin / polylactic acid film, comprising the following steps:

[0047] (1) Preparation of heterogeneous lignin

[0048]First, add 3g of Lignin powder and 10mL of deionized water into a beaker, after stirring, add 0.3g of Span 80, 0.3g of Tween 40, and use an ultrasonic instrument to perform ultrasonic treatment for 10min to ensure that the solution is fully dissolved; then, the completely dissolved The solution was poured into a zirconia ball milling jar equipped with 16 large zirconia ball milling beads with a diameter of 10 mm and 100 small zirconia ball milling beads with a diameter of 6 mm. The speed of the planetary ball mill was set at 480 rpm, and the solution mixture was ball-milled for 24 h, and the milling was interrupted for 30 min every 2 h to prevent overheating. After the ball milling was completed, samples were collected, and the collected samples were freeze-dried for 48 hours before use.

[0049] (2) Preparation...

Embodiment 3

[0052] A preparation method for a heterogeneous lignin / polylactic acid film, comprising the following steps:

[0053] (1) Preparation of heterogeneous lignin

[0054] First, 3g of Lignin powder and 10mL of deionized water were added to the beaker, after stirring, 0.3g of surfactant Tween 80 (TW), 0.3g of carbon nanotube dispersion (TN) were added, and ultrasonic treatment was performed for 10min using an ultrasonic instrument. Make sure that the solution is fully dissolved; then, pour the completely dissolved solution into a zirconia ball milling jar equipped with 16 large zirconia balls with a diameter of 10mm and 100 small zirconia balls with a diameter of 6mm. The speed of the planetary ball mill was set at 480 rpm, and the solution mixture was ball-milled for 24 h, and the milling was interrupted for 30 min every 2 h to prevent overheating. After the ball milling was completed, samples were collected, and the collected samples were freeze-dried for 48 hours before use. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com