Preparation method of graphite-oriented thermal interface material

A thermal interface material and orientation technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high porosity, large contact thermal resistance and total thermal resistance, and achieve low orientation, high density, The effect of low thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

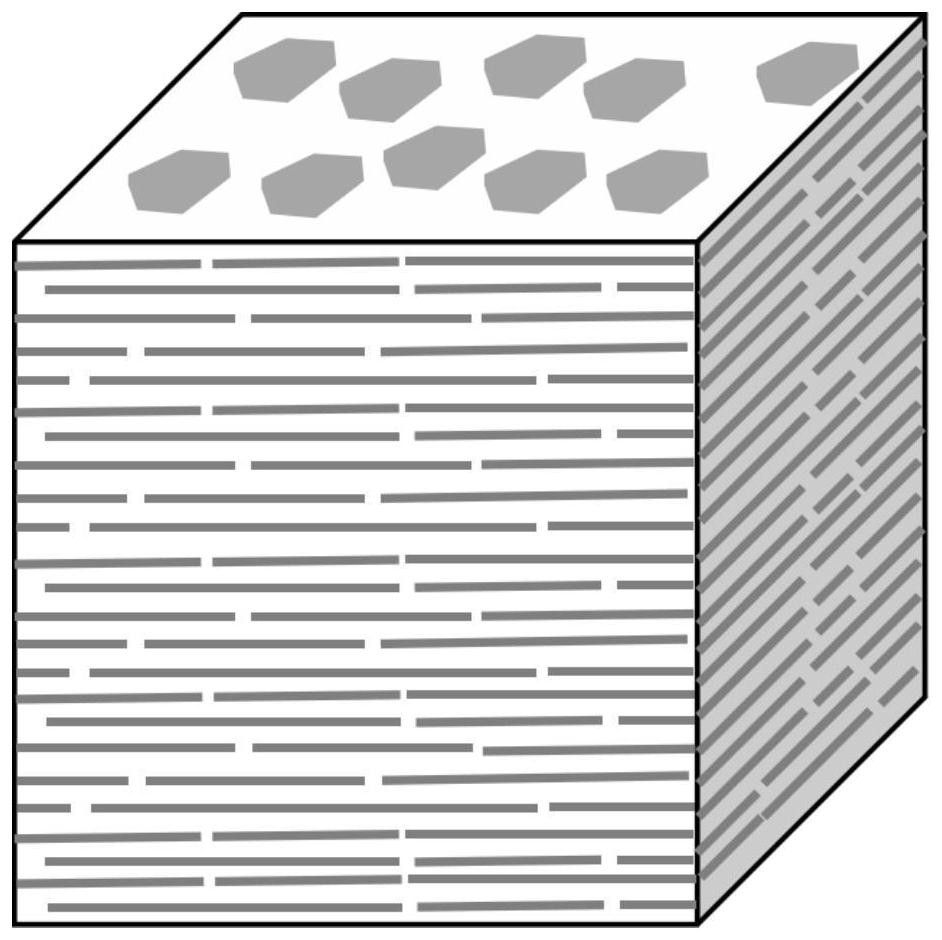

[0054] A method for preparing a graphite filler / polymer-based thermal interface material with oriented structural features: comprising the following steps:

[0055] According to the volume percentage, weigh the corresponding mass of graphite filler, microscopic thermal conductive filler and polymer matrix.

[0056] The graphite filler, the microscopic heat-conducting filler and the polymer matrix are uniformly mixed by means of mechanical mixing (such as planetary stirring, centrifugal stirring) to obtain a mixture. The rotational speed of the stirring rod of the planetary stirring is 100-250 rpm, the stirring time is 2-6 hours, the stirring temperature is -5-100°C, and the stirring environment is a vacuum environment.

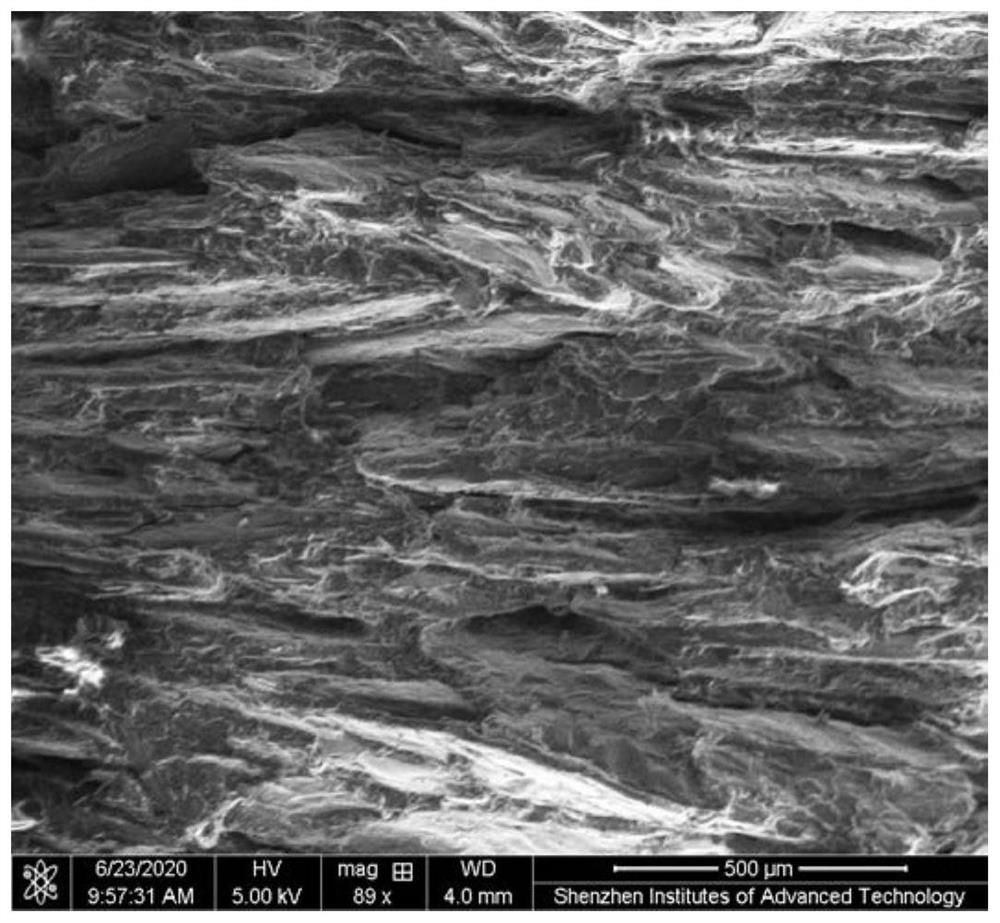

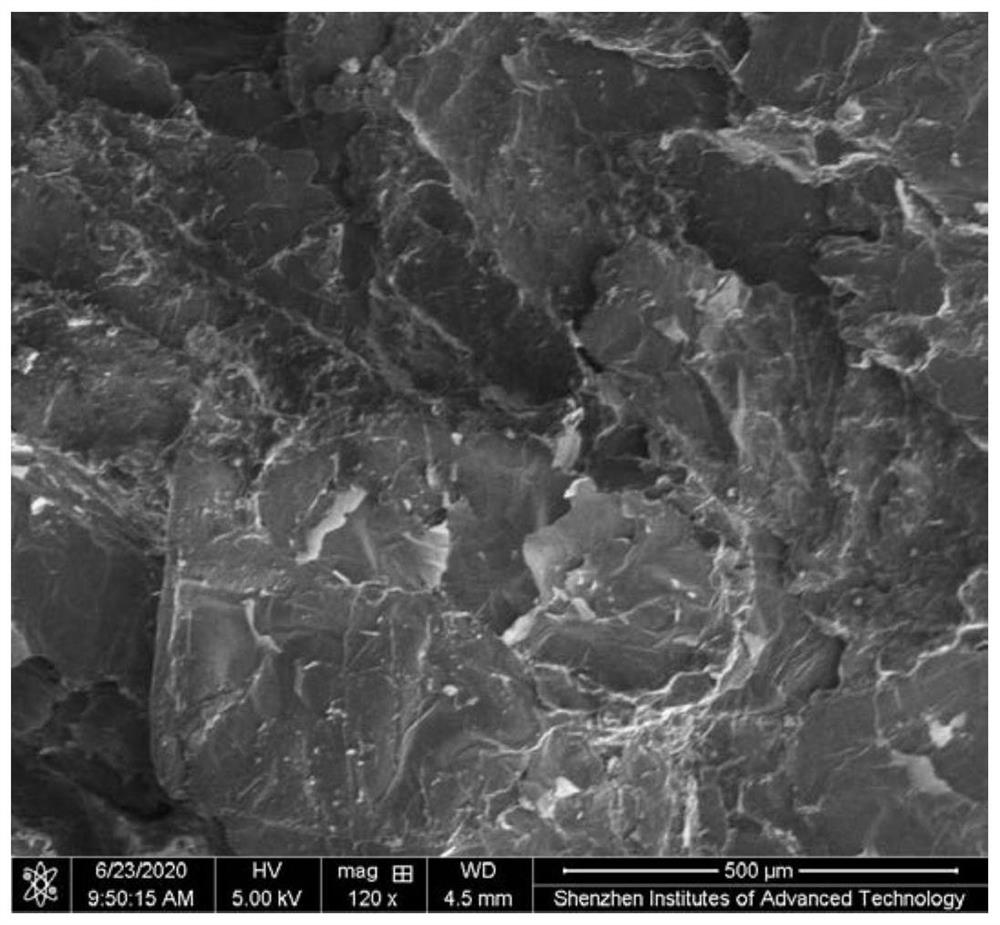

[0057] Orientation treatment (such as slit extrusion process) is adopted to realize the orientation of graphite microflakes in the mixture to obtain a lamellar mixture. The slot extrusion orientation process uses shear force to promote the orientation of grap...

Embodiment 1

[0065] First, flake graphite with an average particle size of 180 microns is used as the graphite filler, aluminum powder with an average particle size of 5 microns is used as the microscopic thermally conductive filler, and hydrogen-containing silicone oil and vinyl silicone oil with an average molecular weight of 1000 are used as the matrix. Through planetary stirring The method is mixed into a mixture with flake graphite volume percentage of 35% and aluminum powder volume percentage of 3%. The rotational speed of the stirring rod of the planetary stirring is 120 rpm, the stirring time is 3 hours, and the stirring temperature is 5°C. After the mixture was evenly stirred, a platinum catalyst was added, and the stirring was continued for 30 minutes. Through slit extrusion, the above mixture was subjected to extrusion orientation treatment, and the thickness of the slit was controlled to be 1 mm. Then the extruded mixture is sent to a refrigeration device with liquid nitrogen ...

Embodiment 2

[0069] First, flake graphite with an average particle size of 280 microns is used as the graphite filler, aluminum powder with an average particle size of 5 microns is used as the microscopic thermally conductive filler, and hydrogen-containing silicone oil and vinyl silicone oil with an average molecular weight of 1000 are used as the matrix. Through planetary stirring The way is mixed into flake graphite volume percentage is 45%, the volume percentage of aluminum powder is 3% mixture. The rotational speed of the stirring rod of the planetary stirring is 120 rpm, the stirring time is 3 hours, and the stirring temperature is 5°C. After the mixture was evenly stirred, a platinum catalyst was added, and the stirring was continued for 30 minutes. Through slit extrusion, the above mixture was subjected to extrusion orientation treatment, and the thickness of the slit was controlled to be 1.5 mm. Then the extruded mixture is sent to a refrigeration device with liquid nitrogen as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com