Cooling liquid distribution type scrap steel distribution port and manufacturing method thereof

A coolant and steel scrap technology, applied in the manufacture of converters, etc., can solve the problems of short life and poor performance, and achieve the effects of prolonging life, maintaining wear resistance and impact resistance, and high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

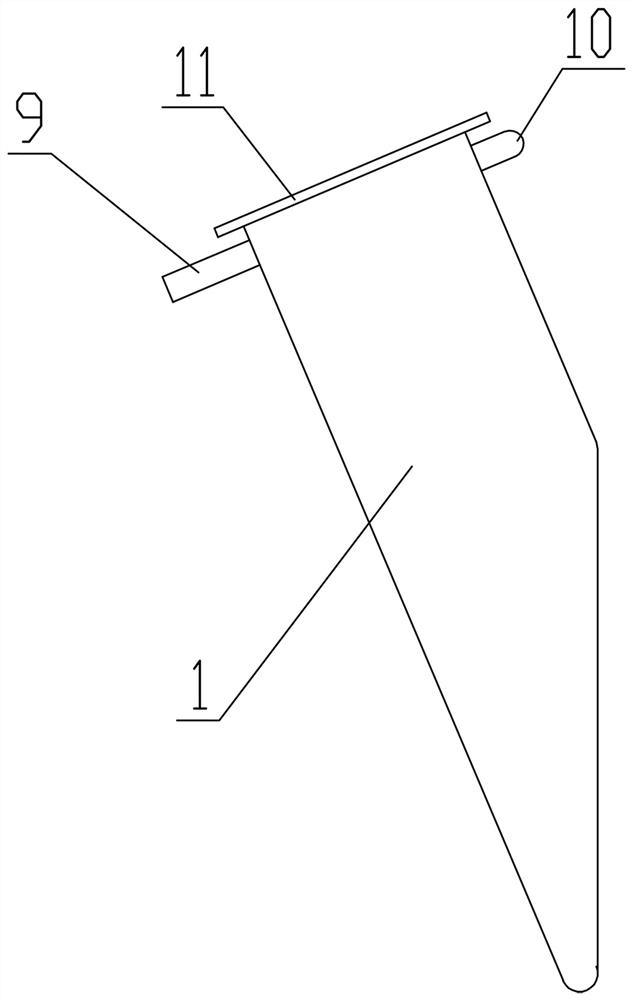

[0043] Example 1 Coolant distribution type scrap steel batching port

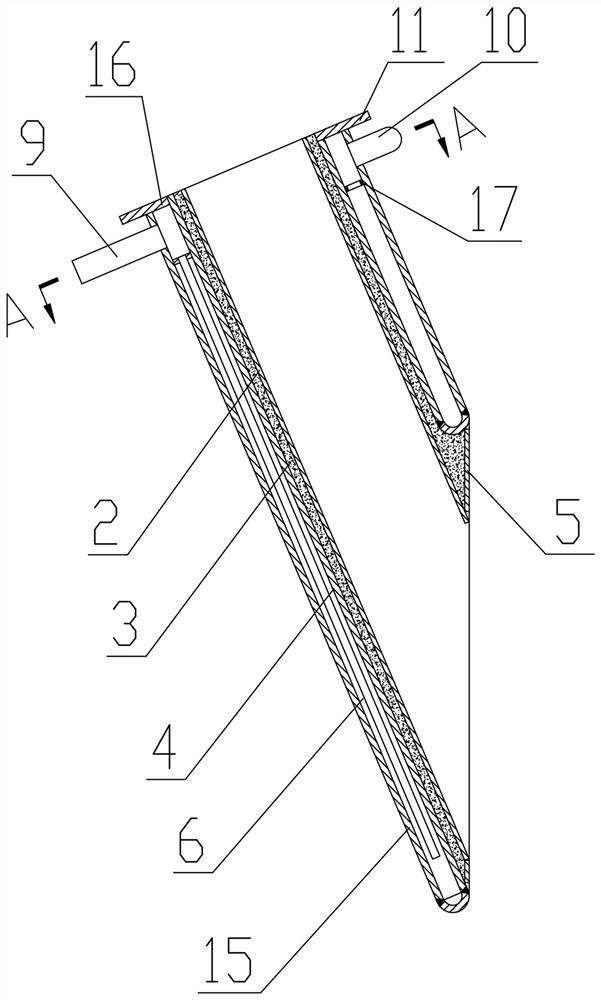

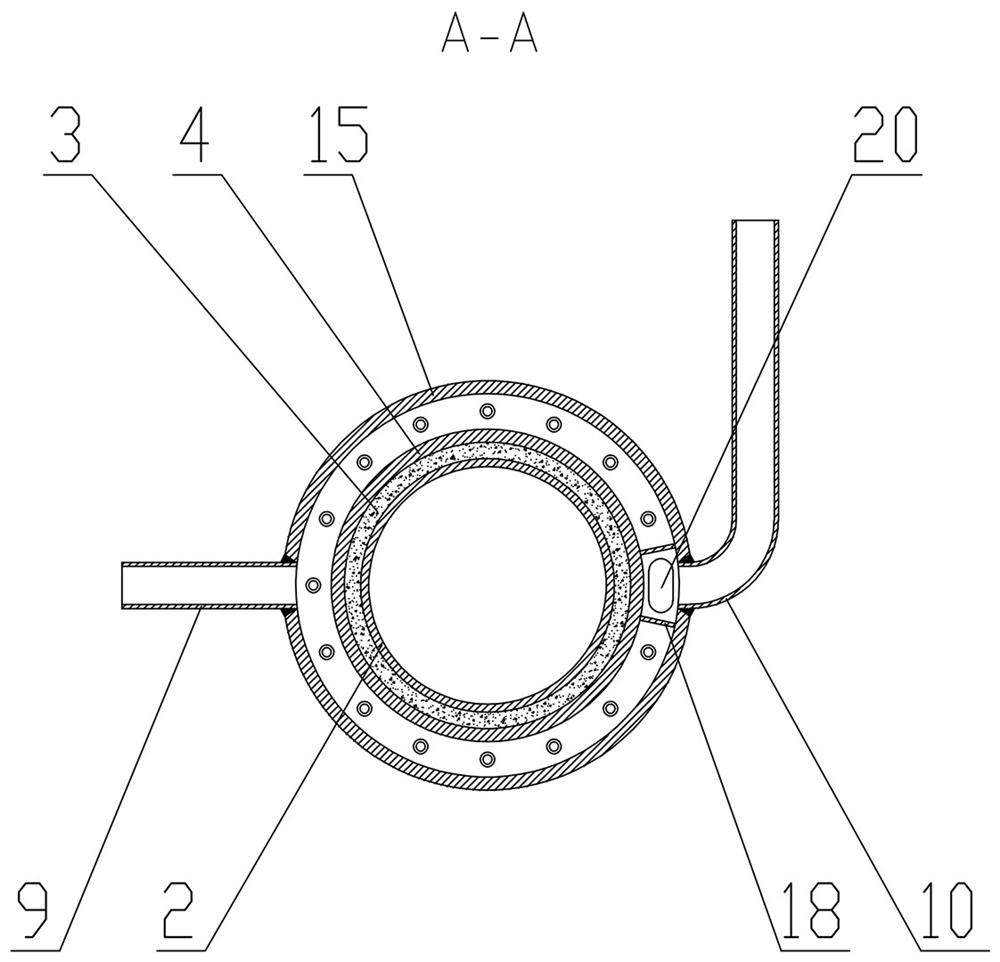

[0044] This example Figure 1 to Figure 6 As shown, it is a cooling liquid distribution type scrap steel batching port, which includes a cylinder body 1, which is an inclined hollow cylindrical structure with upper and lower openings fixed on the converter vaporization cooling flue. In this embodiment, the cross section of the cylinder body 1 is circular, and the cylinder body 1 is arranged on the side wall of the vaporization cooling flue and communicates with the vaporization cooling flue. Since the cylinder body 1 is the channel through which steel scrap enters the converter, there are high requirements for the wear resistance and impact resistance of the cylinder body 1 .

[0045] Since the cylinder 1 is a hollow structure, the cylinder 1 has a cylinder wall. In order to improve the wear resistance and impact resistance of the cylinder 1, the cylinder wall is set into a multi-layer structure: as figu...

Embodiment 2

[0054] Example 2 Manufacturing method of cooling liquid distribution type scrap steel batching port

[0055] This embodiment is a manufacturing method of a cooling liquid distribution type scrap steel batching port, which is used to make the cooling liquid distribution type scrap steel batching port in Example 1. The manufacturing method of the coolant distribution type scrap steel batching port in this embodiment comprises the following steps carried out in sequence:

[0056] Make the cooling circulation layer: get the low-temperature cooling layer 4 or the outer wall 15 of the cylinder, and set the first dividing plate 17 and the second dividing plate 18 in a welding manner on the outer wall of the low-temperature cooling layer 4 or the inner wall of the outer wall 15 of the cylinder. The circulation pipe 19 is set on the first dividing plate 17 by welding after punching, and the water return port 20 is formed by punching. According to the setting positions of the first divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com