Manufacturing method of floating type tidal current power generation equipment installation structure

A tidal current power generation and equipment installation technology, which is applied in mechanical equipment, engine manufacturing, ocean energy power generation, etc., can solve the problems of large floating warehouse structure, large limitations, high cost, etc., to prolong the erosion time, facilitate installation and fixation, and increase stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

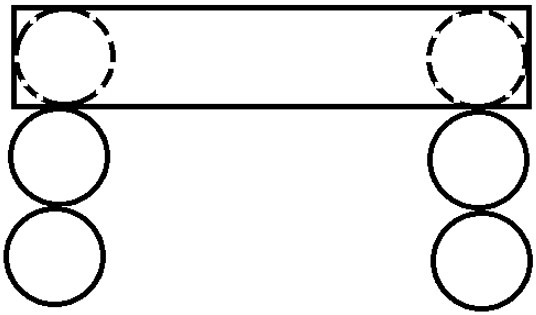

[0015] A manufacturing method for the installation structure of floating tidal current power generation equipment. According to the total weight of the power generation equipment required to be placed, a floating installation structure frame is constructed through buoyancy calculation. The installation structure frame is composed of several buoyancy tubes connected. The hollow tube of the corresponding size corresponding to the requirements is expanded and filled with light corrosion-resistant foam material, and the two ends of the hollow tube are sealed to form a buoyancy tube.

[0016] The fabrication of the floating installation structure frame is carried out in a dry water dock connected to sea water. After the fabrication is completed, the gate is opened to release water into the dry water dock. After the floating installation structure frame floats, it is towed to the designated place for anchoring. Due to the large size of the floating installation structure frame, many ...

Embodiment 2

[0019] As a specific structural design of Example 1, the hollow tube is a steel tube. The steel pipe is chosen as the material of the hollow pipe, because it has a certain strength, so that the frame has a certain ability to resist the waves in the sea.

[0020] Preferably, ribs and steel mesh are welded on the outer surface of the steel pipe, and the frame is sprayed with marine concrete to form a platform frame. The laid ribs and steel mesh are sprayed with marine concrete to protect the outer surface of the steel pipe and make the platform frame meet the installation requirements. The thickness of the sprayed grout is determined by the specific buoyancy design; the design of the ribs and steel mesh is also Another advantage is that if the cement is directly poured, it will be insufficiently emphasized due to the thin thickness, resulting in bursting; if the thickness is thick, the strength is enough, but the platform cannot float in sea water.

[0021] As a preference, pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com