Speed regulation method of energy recovery system of speed regulation type double four-quadrant frequency converter

A four-quadrant frequency converter and energy recovery technology, which is applied in the direction of non-variable pumps, machines/engines, steam engine devices, etc., can solve the problems of energy recovery efficiency and variable speed adjustment, so as to reduce energy consumption, improve efficiency, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

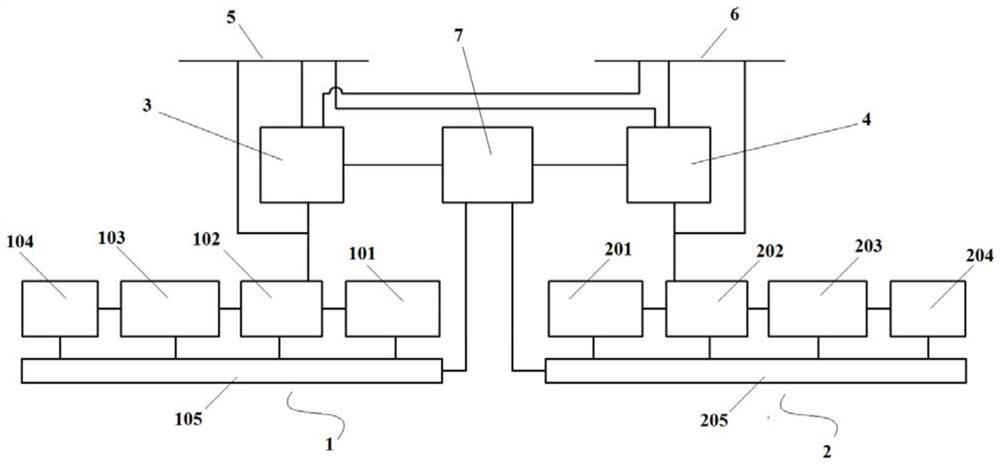

[0069] This embodiment provides an energy recovery system for a speed-regulating double four-quadrant inverter, such as image 3 As shown, including the first SHRT1 and the second SHRT2;

[0070] The first SHRT1 includes the first sintering blower 101, the first motor 102, the first transmission clutch 103 and the first steam turbine 104 which are connected coaxially in sequence, and also includes the first sintering blower 101, the first motor 102, the first transmission clutch 103 A first unit DCS controller 105 electrically connected to the first steam turbine 104;

[0071] The second SHRT2 includes the second sintering fan 201, the second motor 202, the second transmission clutch 203 and the second steam turbine 204 which are connected coaxially in sequence, and also includes the second sintering fan 201, the second motor 202, the second transmission clutch 203 A second unit DCS controller 205 electrically connected to the second steam turbine 204;

[0072] The first mot...

Embodiment 2

[0077] This embodiment provides a speed regulation method for an energy recovery system of a speed-adjustable double four-quadrant inverter. The speed regulation method uses the energy recovery system for a speed-adjustable double four-quadrant inverter in Embodiment 1. Specifically, the method includes the following steps:

[0078] Step 1, speed reduction control:

[0079] Step 30201, the DCS controller 105 of the first unit and the DCS controller 205 of the second unit give the PLC controller 7 of the frequency converter the target speed to be adjusted, and the PLC controller 7 of the frequency converter calculates the corresponding frequency according to the target speed;

[0080] Step 30202, send an instruction through the inverter PLC controller 7, and simultaneously reduce the speed of the first motor 102 and the second motor 202 through the regulation of the first four-quadrant inverter 3 and the second four-quadrant inverter 4;

[0081] Step 30203, during the decelera...

Embodiment 3

[0099] This embodiment provides a control method for an energy recovery system of a speed-regulating double four-quadrant inverter, which uses the energy recovery system of a speed-adjusting double four-quadrant inverter in Embodiment 1. Specifically, the method includes the following steps:

[0100] Step 1, start up to power frequency rated speed control:

[0101] Step 101, when starting, the DCS controller 105 of the first unit and the DCS controller 205 of the second unit issue a start command to the PLC controller 7 of the inverter, controlled by the PLC controller 7 of the inverter, and pass through the DCS controller 205 of the second unit For regulation and control, first close the damper of the second sintering fan 201 to an opening of 5% to 10%, and then start the first sintering fan 101;

[0102] Step 102, according to the speed-up rate set by the inverter PLC controller 7, the first motor 102 is raised to a power frequency of 50 Hz through the regulation of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com