Thermal power plant boiler soot blower odd-even operation control system and method

A soot blowing technology for thermal power plants and boilers, which is applied to combustion methods, lighting and heating equipment, and removal of solid residues. It can solve the problems of increasing the labor intensity of operating personnel and reducing the automation level of unit operation, so as to improve flexibility and Convenience, reduced labor intensity, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

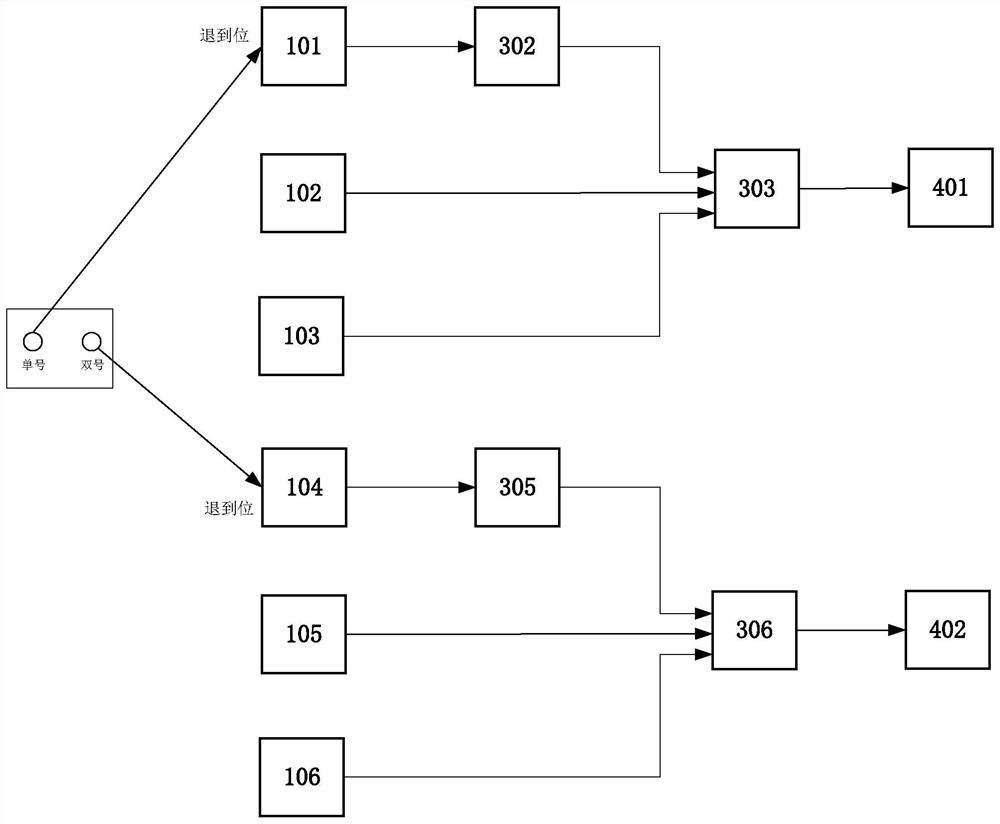

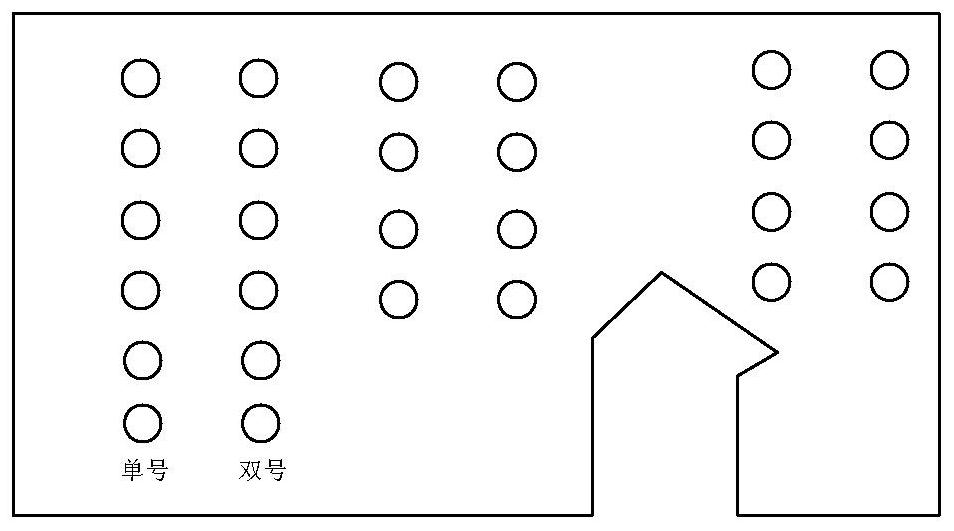

[0030] A 660MW unit in a power plant has a total of 31 long sootblowers on the left and right sides of the furnace, numbered L1-L31, and four floors, with 24 short sootblowers on each floor, numbered A1-A24, B1-B24 , C1-C24, D1-D24. After modifying and perfecting the original soot blowing control logic, the operator only needs to select single number soot blowing, double number soot blowing or all soot blowing before the start of soot blowing program control to realize single number, double number or all soot blowing Soot blower, simple and convenient operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com