Temperature and calcium ion concentration two-parameter sensor and preparation method

A calcium ion, dual-parameter technology, used in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problem of inability to achieve temperature and calcium ion concentration sensing accuracy requirements, low applicability of optical fiber sensors, and complex preparation process and other problems, to achieve the effect of spectral subdivision, simple structure and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

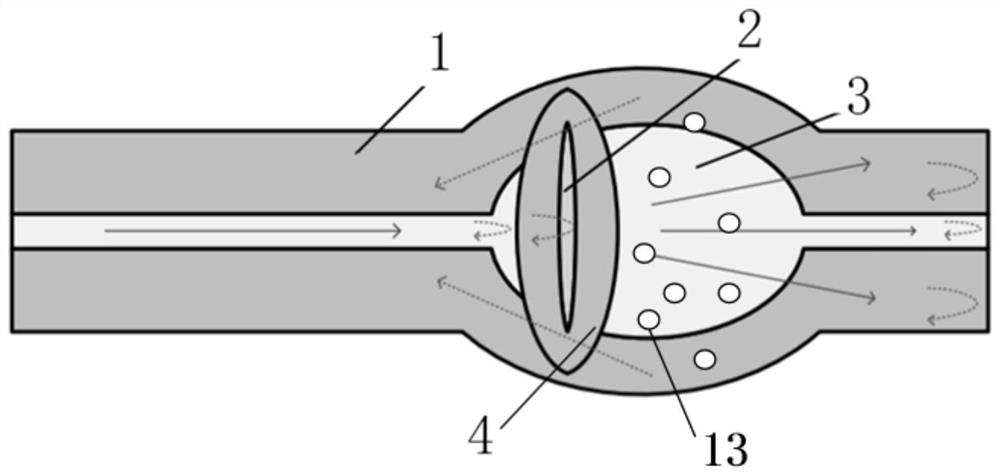

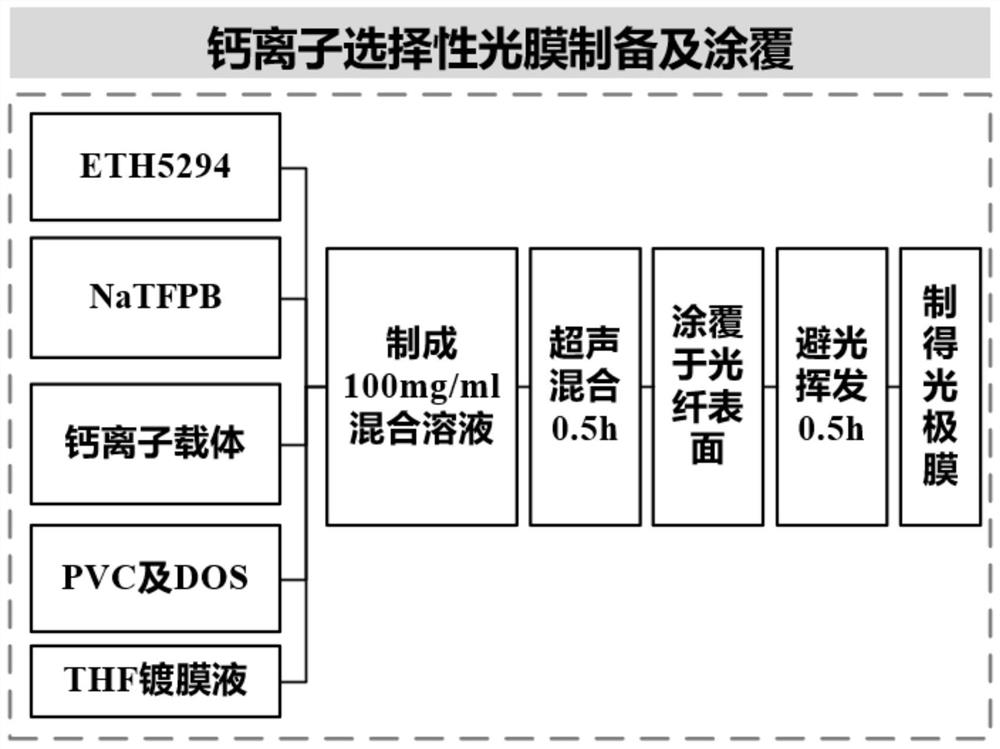

[0039] Such as Figure 1 to Figure 3 As shown, this embodiment provides a method for preparing a dual-parameter sensor of temperature and calcium ion concentration, which specifically includes the following steps: (a) preparing a thick cone interference structure 10 with an internal air fine cavity 13: step a1, combining two sections of single-mode The optical fiber is placed in the fusion splicer and welded by expanding the diameter of the light cone to form a thick cone; step a2, perform high-power instantaneous discharge on the thick cone, so that an air slit 2 is formed inside the thick cone; step a3, in the thick cone area Perform multiple discharges to form a thick cone structure containing the inner air fine cavity 13; (b) prepare the calcium ion selective photopolar film: step b1, the components of the calcium ion selective photode film of ETH5418 for the chromogenic ionophore The dosage is as follows, ETH5294 (5mmol / kg), NaTFPB (10mmol / kg), cation carrier (calcium ion...

Embodiment 1

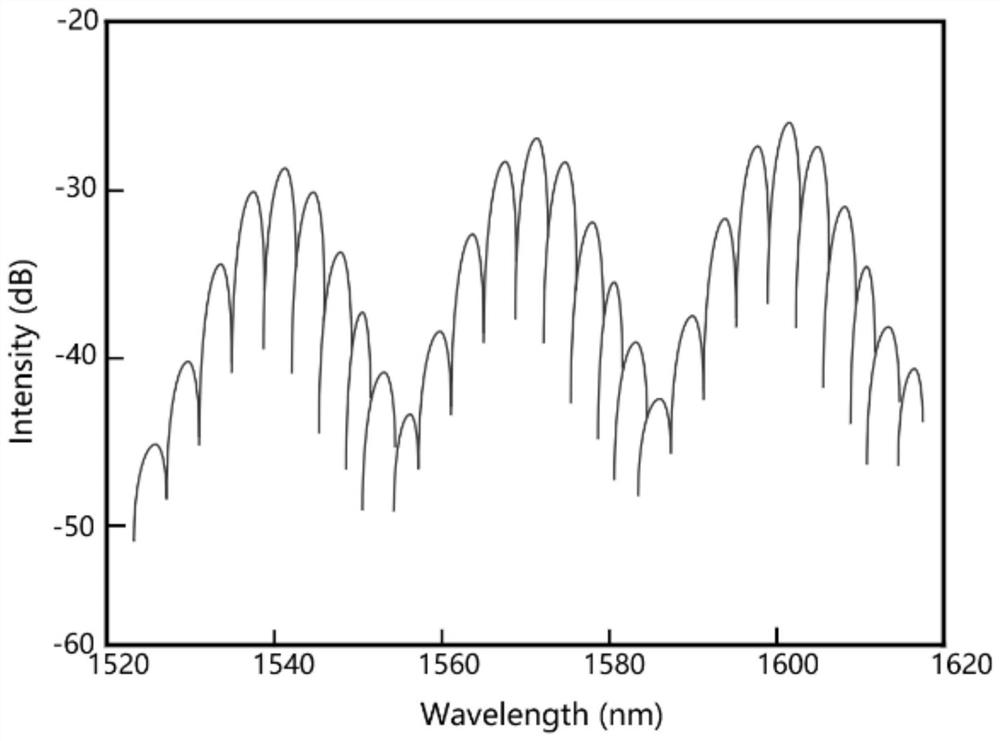

[0046] The optical fiber that the present invention adopts is the common single-mode optical fiber that model is SFM-28, cladding 1 diameter 125um, fiber core 3 diameter 9um, it is placed on the 80S high-precision single-core fusion splicer of Japanese Fujikura company on another SFM In the fusion splicer of -28 ordinary single-mode optical fibers, use the expanded diameter light cone fusion splicing mode to perform high-power instantaneous discharge to form an air slit 2 inside the thick cone, and perform multiple discharges in the thick cone area to form an internal The coarse cone structure of the air fine cavity forms an inner fine cavity with an axial cavity length of 6-7um and a radial length of the coarse cone cone area of 241um. That is to make the required thick cone interference structure 10 temperature calcium ion concentration dual parameter sensor structure. The spectrogram is the shape of a large envelope overlapping a small envelope, such as figure 2 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Cladding diameter | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com