Flow field measuring device and flow field measuring system

A measuring device and measuring system technology, which is applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc., can solve the problems of high maintenance cost and difficult wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In order to reduce the difficulty of wiring in an actual industrial production site and reduce maintenance costs, an embodiment of the present application provides a flow field measurement system and a flow field measurement device used in the system.

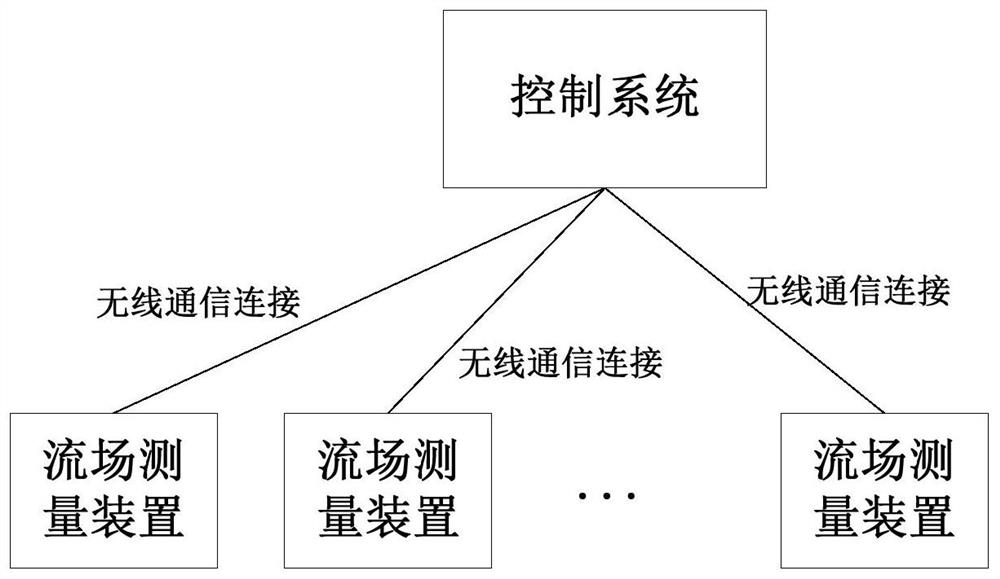

[0040] See figure 1 As shown, the flow field measurement system provided by the embodiment of the present application includes:

[0041] A plurality of flow field measuring devices are respectively arranged in each equipment to be tested.

[0042] The control system is wirelessly connected with each flow field measurement device to receive the flow field measurement information detected by each flow field measurement device.

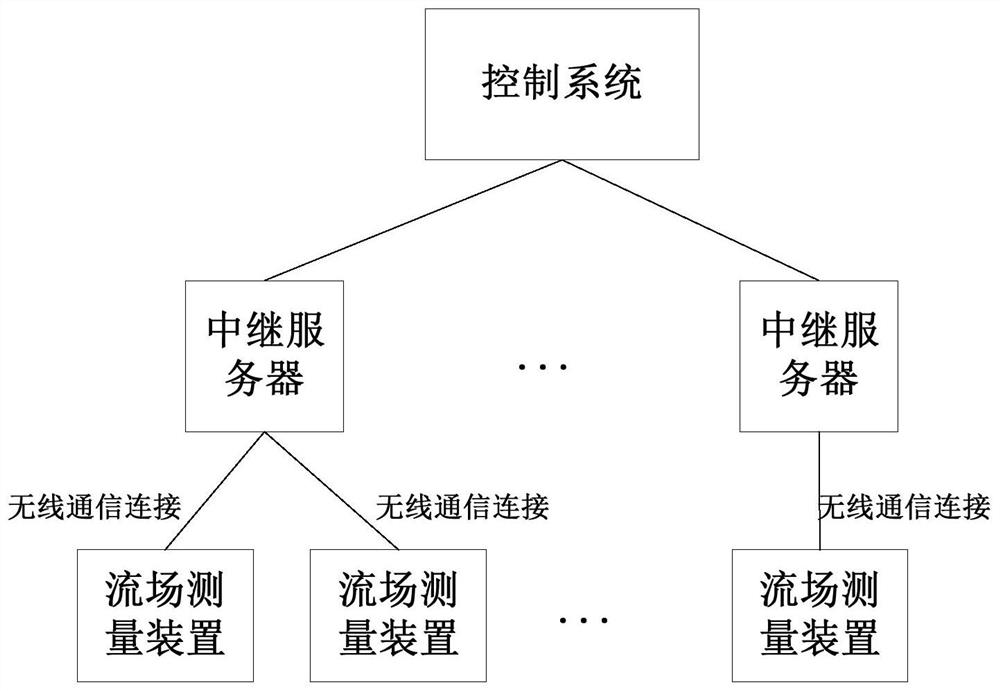

[0043] It should be noted that in practical applications, industrial production sites are often very large, and the distances between different devices under test are often not very close. Therefore, if the flow field measurement device is directly connected to the control system, depending on th...

Embodiment 2

[0087] On the basis of the first embodiment, the embodiment of the present application is described by taking a specific flow field measuring device and system structure applied in a thermal power plant as an example.

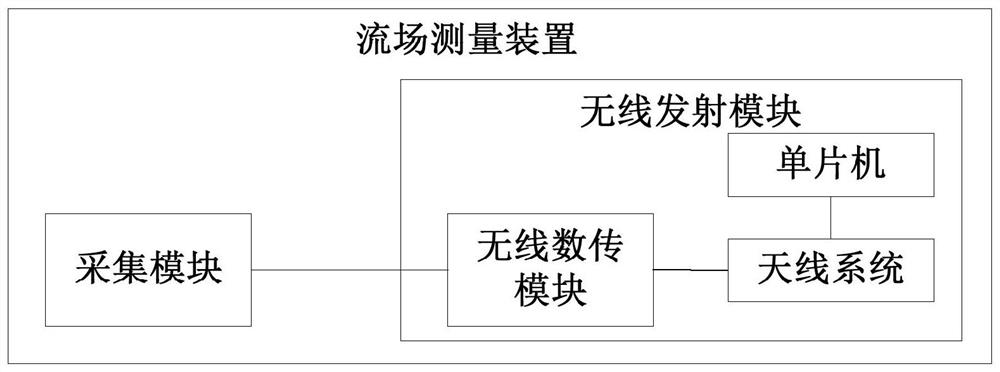

[0088] see Figure 8 as shown, Figure 8 It is a schematic structural diagram of a flow field measuring device provided in an embodiment of the present application, which includes: a sensing module (1), a data processing module (2) and a wireless transmitting module (3).

[0089] The casings of the three modules are made of corrosion-resistant stainless steel to adapt to the actual flue gas environment with high temperature, high dust and high corrosiveness; the casings of the three modules are fixedly connected by threads. The three modules are connected through plug-in terminals to realize mutual information exchange and power supply. Among them, the maximum diameter d of the flow field measurement device composed of three modules is less than or equal to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com