Method for rapidly determining content of titanium in ferrotitanium

A technology for rapid determination of titanium content, applied in chemical analysis by titration, etc., can solve problems such as unsuitable for rapid analysis, difficult to master operation, and complicated methods, and achieves meeting the needs of on-site production, using less reagents, and analyzing time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

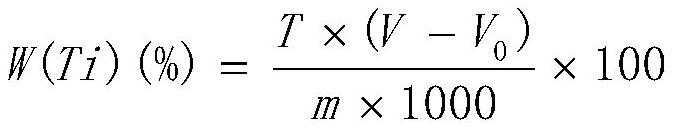

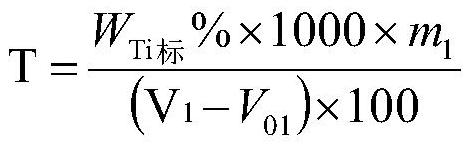

[0050] Embodiment 1: A kind of method of fast determination titanium content in ferro-titanium

[0051] Weigh 0.5000g of ferrotitanium standard sample (YSBC18604-08) into a 500mL Erlenmeyer flask, add (1+5) sulfuric acid 140mL, dissolve the sample at low temperature, add (1+1) hydrochloric acid 60mL, after the sample is dissolved, add Add about 0.5g of sodium bicarbonate to 1g of aluminum flake, immediately cover the mouth of the Erlenmeyer flask with a porcelain crucible lid, and heat to dissolve on a low-temperature electric furnace. After dissolving, boil for 5-6 minutes, remove and cool, remove the lid of the porcelain crucible, immediately add 20mL saturated ammonium sulfate solution, immediately titrate with ferric ammonium sulfate standard titration solution until the purple color disappears, add 50g / L ammonium thiocyanate Continue to titrate 5mL of the solution to red, and keep the red color for 2 minutes after fully shaking as the end point. The measurement result is...

Embodiment 2

[0053] Embodiment 2: a kind of method of fast determination titanium content in ferro-titanium

[0054] Weigh 0.5000g ferro-titanium standard sample (YSBC19605-04) into a 500mL Erlenmeyer flask, add (1+5) sulfuric acid 140mL, dissolve the sample at low temperature, add (1+1) hydrochloric acid 60mL, after the sample dissolves, add Add about 0.5g of sodium bicarbonate to 1g of aluminum flake, cover the porcelain crucible immediately, and heat to dissolve on a low-temperature electric furnace. After dissolving, boil for 5-6 minutes, remove and cool, remove the lid of the porcelain crucible, immediately add 20mL saturated ammonium sulfate solution, immediately titrate with ferric ammonium sulfate standard titration solution until the purple color disappears, add 50g / L ammonium thiocyanate Continue to titrate 5mL of the solution to red, and keep the red color for 2 minutes after fully shaking as the end point. The measurement result is 38.60%, the standard value is 38.81%, and the...

Embodiment 3

[0056] Embodiment 3: a kind of method of fast determination titanium content in ferro-titanium

[0057] Weigh 0.5000g ferro-titanium sample and place it in a 500mL Erlenmeyer flask, add (1+5) sulfuric acid 140mL, dissolve the sample at low temperature, add (1+1) hydrochloric acid 60mL, add 1g aluminum flakes after the sample is dissolved, add About 0.5g sodium bicarbonate, cover the porcelain crucible immediately, and dissolve it by heating on a low-temperature electric furnace. After dissolving, boil for 5-6 minutes, remove and cool, remove the lid of the porcelain crucible, immediately add 20mL saturated ammonium sulfate solution, immediately titrate with ferric ammonium sulfate standard titration solution until the purple color disappears, add 50g / L ammonium thiocyanate Continue to titrate 5mL of the solution to red, and keep the red color for 2 minutes after fully shaking as the end point. The measurement results of the two parallel samples were 22.50% and 22.46%, respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com