Unsealing method of metal ceramic packaged crystal oscillator with chip injection molding packaging

A crystal oscillator and cermet technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low unpacking efficiency and inability to ensure the integrity of the internal structure, achieve high unpacking efficiency, and avoid acid corrosion time. Long-lasting, damage-preventing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

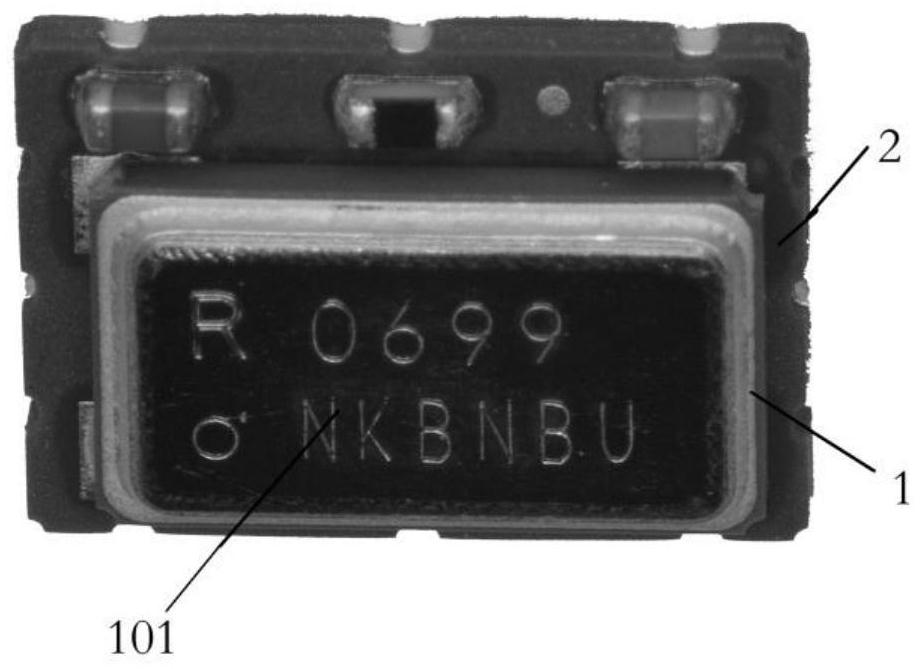

[0060] As an embodiment of the present invention, taking the 51099-20MHz crystal oscillator of RAKON Company as an example, the unsealing method of the cermet encapsulated crystal oscillator of the chip injection molding package includes the following steps:

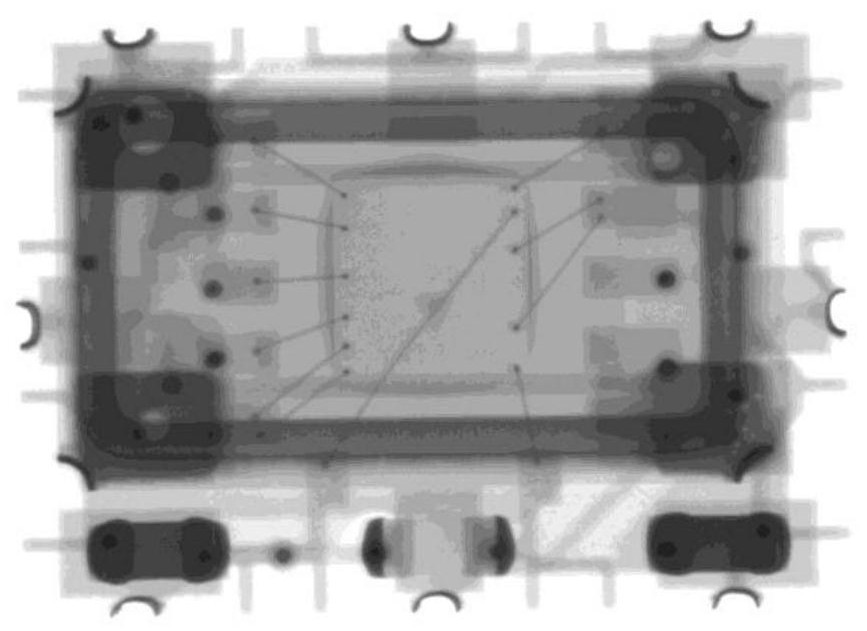

[0061] Step 1. Carry out X-ray inspection on the internal structure of the crystal oscillator to obtain the internal chip installation position of the crystal oscillator, the chip bonding method, the solder joint position of the chip cavity 1, and the chip installation position.

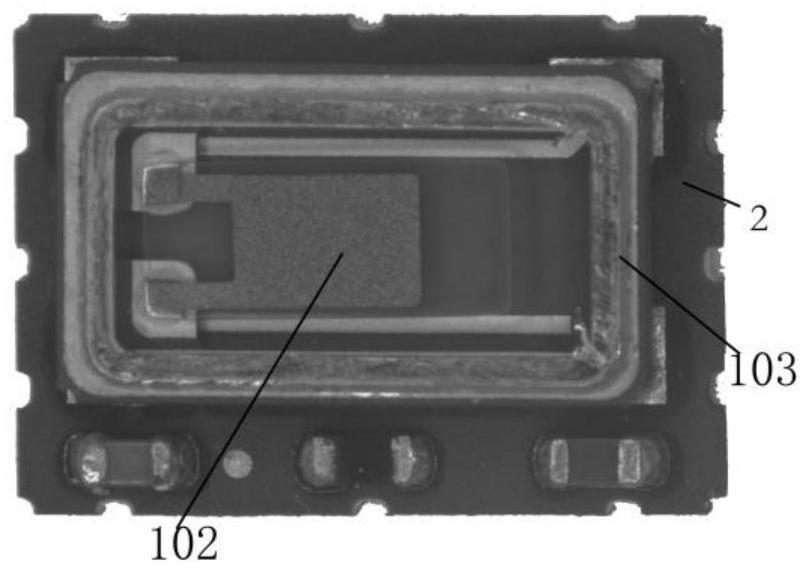

[0062] Step 2. According to the internal information of the crystal oscillator, use the mechanical unsealing method to unseal the wafer cavity 1: use flat pliers to fix the sample, and use a small hand-held grinder to grind the metal cover 101 to a sufficiently thin welding seam , aim the blade at the weld seam after grinding, apply pressure to the blade to insert the blade edge into the weld seam until the cover plate falls off, exposing the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com