Miniature column type lithium ion battery sealing structure, battery and manufacturing method thereof

A lithium-ion battery and sealing structure technology, applied in sealing materials, secondary batteries, structural parts, etc., can solve the problems of limited volume of micro-column batteries, shortened battery life, electrolyte leakage, etc., to reduce electrolyte leakage risk, increased volume, good sealing performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

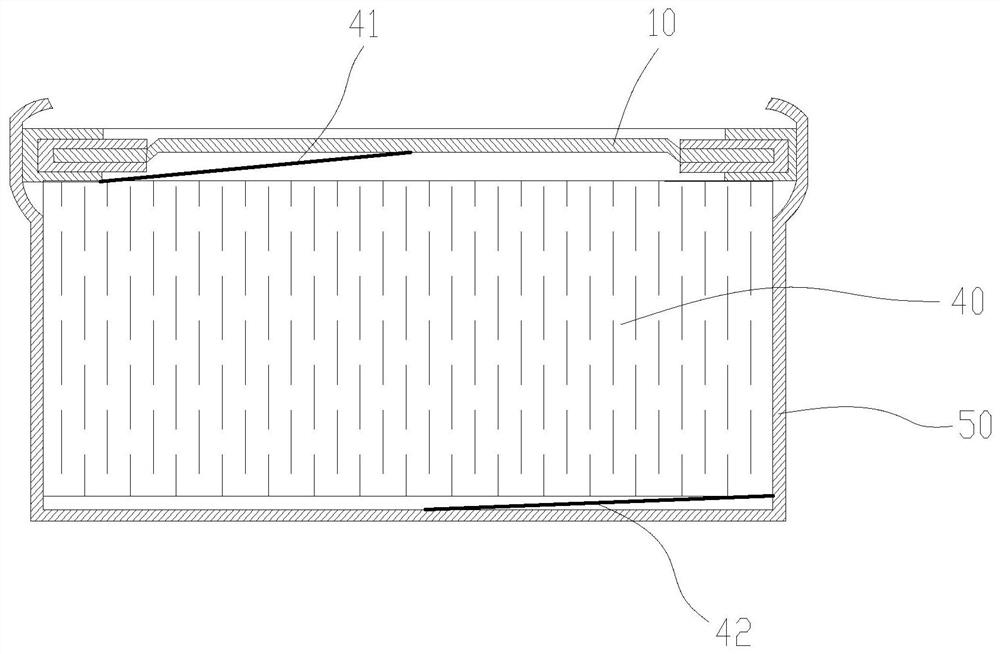

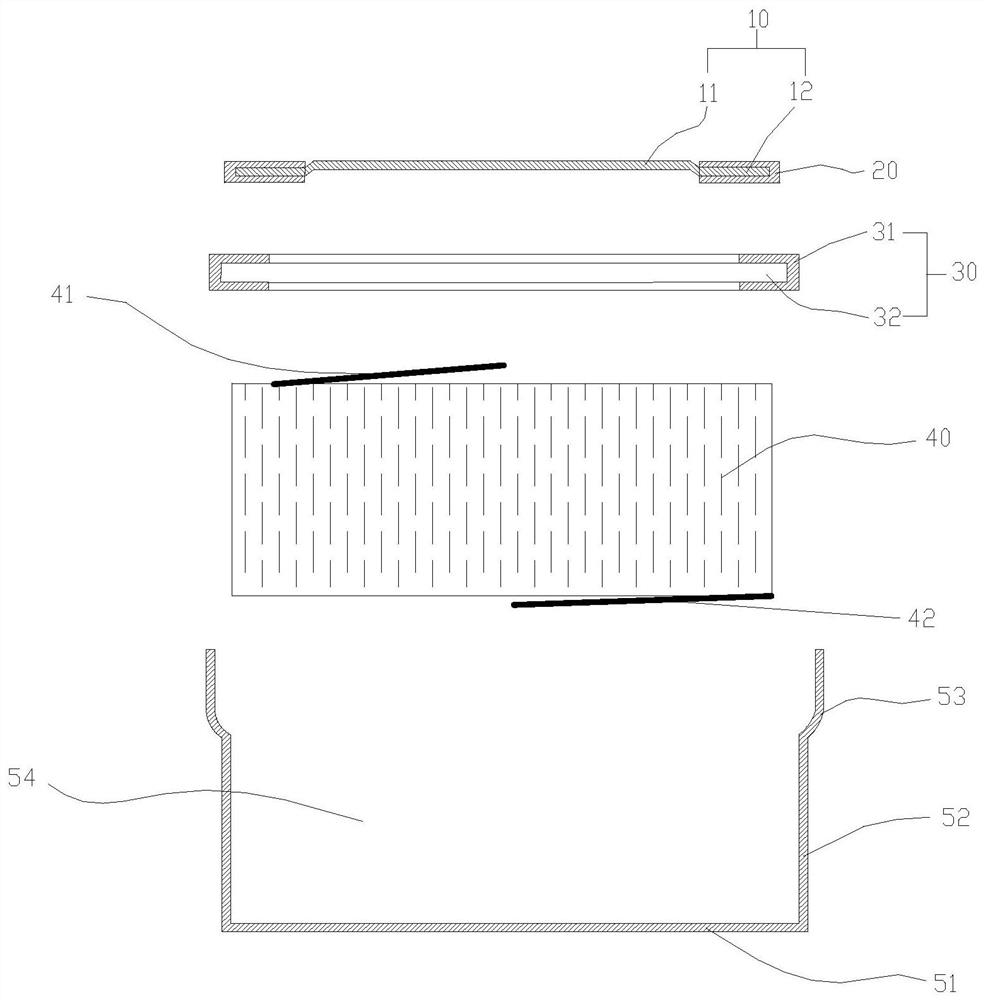

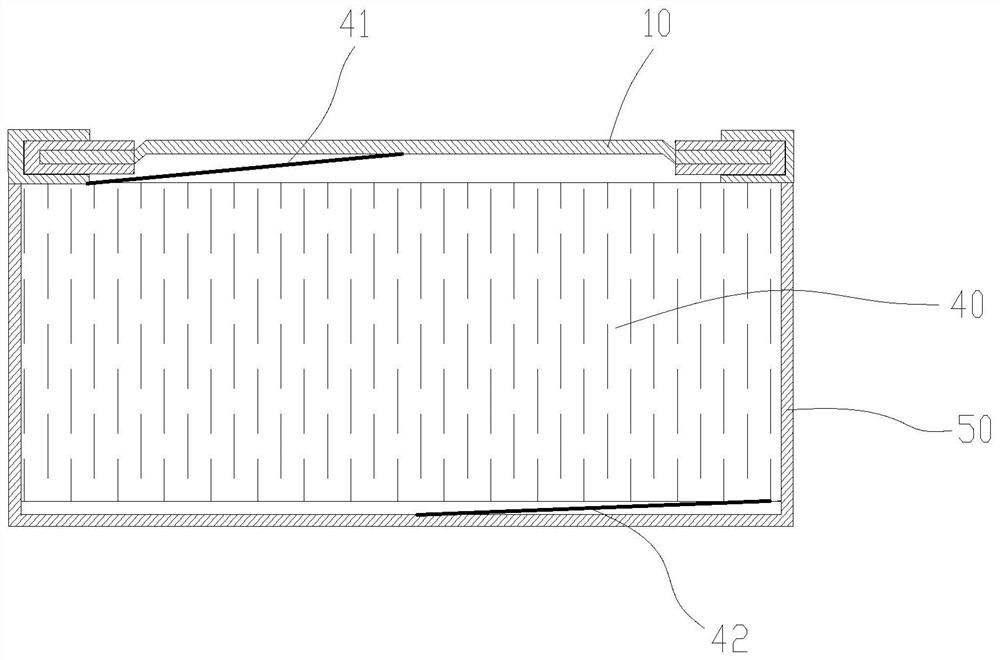

[0039] refer to figure 1 , figure 2, a micro-column lithium-ion battery sealing structure, a housing 50 with a bottom surface 51 and a side wall 52 extending around the edge of the bottom surface 51, and an upper cover 10 connected to the top surface of the housing 50; specifically, the housing 50 is Cylindrical structure, the upper cover 10 is a flat sheet structure, the shell 50 and the upper cover 10 are made of metal material with a thickness of 0.1-0.35mm, avoiding the double shell structure, so that the inner diameter of the shell 50 can be maximized, thereby The maximum capacity of the battery cavity 54 is guaranteed; in the present embodiment, the thickness of the housing 50 and the upper cover 10 is made of stainless steel with a thickness of 0.2mm; the top surface of the housing 50 is open, and the upper cover 10 and the side wall 52 of the housing 50 The sealing ring 30 is sealed and connected to form a hollow and sealed battery cavity 54. Specifically, the materi...

Embodiment 2

[0046] Embodiment 2: a kind of miniature cylindrical lithium ion battery, comprises the sealing structure of the miniature cylindrical lithium ion battery in embodiment 1, also comprises the electrode assembly 40, electrolytic solution that is located at the inside of battery chamber 54; On the electrode assembly 40 opposite The two sides are respectively connected to the inner wall of the bottom surface 51 of the housing 50 and the inner wall of the upper cover 10 through the positive conductor 42 and the negative conductor 41. In this embodiment, the positive conductor 42 can also be welded to the inner surface of the side wall 52 of the housing 50 , to realize battery charging or output electric energy externally.

[0047] In another embodiment, such as Figure 5 As shown, the negative electrode conductor 41 is connected to the inner wall of the upper cover 10, and the positive electrode conductor 42 is connected to the side wall of the housing or the edge of one end of the...

Embodiment 3

[0048] Embodiment 3: a kind of method of manufacturing mini-pillar type lithium-ion battery, this method is used for manufacturing the micro-pillar type lithium-ion battery in embodiment 2, comprises the steps:

[0049] S1. A sealing insulating layer 20 is provided around the periphery of the upper cover 10 by injecting glue or wrapping;

[0050] Specifically, the sealing and insulating layer 20 is provided on the periphery of the upper cover 10 by means of glue injection or edge wrapping, and the material of the sealing and insulating layer 20 includes one of polypropylene, propylene-ethylene copolymer, polyether ether ketone, and polyvinylidene fluoride. or more.

[0051] S2. Provide a sealing ring 30 with an "L"-shaped cross-section. The inner diameter of the sealing ring 30 is greater than or equal to the outer diameter of the upper cover 10 after the sealing insulating layer 20 is set; the upper cover 10 is placed in the sealing ring 30, and the "L" The upper end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com