Composite fiber modified asphalt mixture with excellent performance, and preparation method thereof

A technology of composite fiber and modified asphalt, which is applied in the field of road engineering and can solve problems such as limited road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

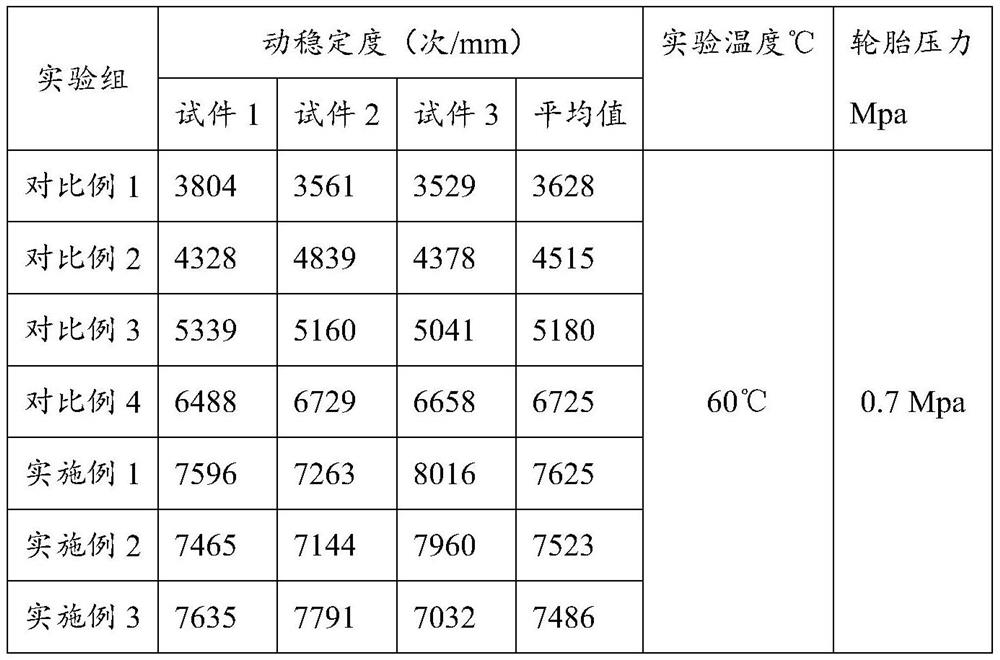

Examples

Embodiment 1

[0029] The composite fiber modified asphalt mixture with excellent performance is composed of the following raw materials in parts by weight:

[0030] 5 parts of SBS modified asphalt, 10 parts of mineral powder, 95 parts of aggregate, and 0.3 parts of composite fiber stabilizer;

[0031] Wherein, the composite fiber stabilizer includes lignin fibers, polyacrylonitrile fibers and sepiolite fibers in proportions by weight of 35:27:15;

[0032] Wherein, the aggregate comprises a weight ratio of 1:0.5 coarse aggregate and fine aggregate;

[0033] Its preparation method of composite fiber modified asphalt mixture with excellent performance comprises the following steps:

[0034] 1) Weigh each raw material according to the proportion by weight, then place the lignin fiber, polyacrylonitrile fiber and sepiolite fiber in the reaction kettle, and mechanically stir for 80 minutes to obtain the composite fiber stabilizer;

[0035] 2) Place the weighed SBS modified asphalt in an oven an...

Embodiment 2

[0039] The composite fiber modified asphalt mixture with excellent performance is composed of the following raw materials in parts by weight:

[0040]4.5 parts of SBS modified asphalt, 8 parts of mineral powder, 90 parts of aggregate, and 0.2 parts of composite fiber stabilizer;

[0041] Wherein, the composite fiber stabilizer includes lignin fibers, polyacrylonitrile fibers and sepiolite fibers in a weight ratio of 32:25:13;

[0042] Wherein, the aggregate comprises a proportion by weight of 1:0.4 coarse aggregate and fine aggregate;

[0043] Its preparation method of composite fiber modified asphalt mixture with excellent performance comprises the following steps:

[0044] 1) Weigh each raw material according to the proportion by weight, then place the lignin fiber, polyacrylonitrile fiber and sepiolite fiber in the reaction kettle, and mechanically stir for 60 minutes to obtain the composite fiber stabilizer;

[0045] 2) Place the weighed SBS modified asphalt in an oven a...

Embodiment 3

[0049] The composite fiber modified asphalt mixture with excellent performance is composed of the following raw materials in parts by weight:

[0050] 6 parts of SBS modified asphalt, 12 parts of mineral powder, 100 parts of aggregate, and 0.5 part of composite fiber stabilizer;

[0051] Wherein, the composite fiber stabilizer includes lignin fibers, polyacrylonitrile fibers and sepiolite fibers in proportions by weight of 38:29:17;

[0052] Wherein, the aggregate comprises a weight ratio of 1:0.6 coarse aggregate and fine aggregate;

[0053] Its preparation method of composite fiber modified asphalt mixture with excellent performance comprises the following steps:

[0054] 1) Weighing each raw material according to the proportion by weight, then putting the lignin fiber, polyacrylonitrile fiber and sepiolite fiber in the reaction kettle, and mechanically stirring for 100 minutes to obtain the composite fiber stabilizer;

[0055] 2) Place the weighed SBS modified asphalt in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com