NiFe-LDH cement-based composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material, cement-based technology, applied in the field of environmental protection, can solve problems such as electromagnetic wave pollution, achieve good structural strength, excellent electromagnetic wave absorption performance, and improve the effect of electromagnetic wave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

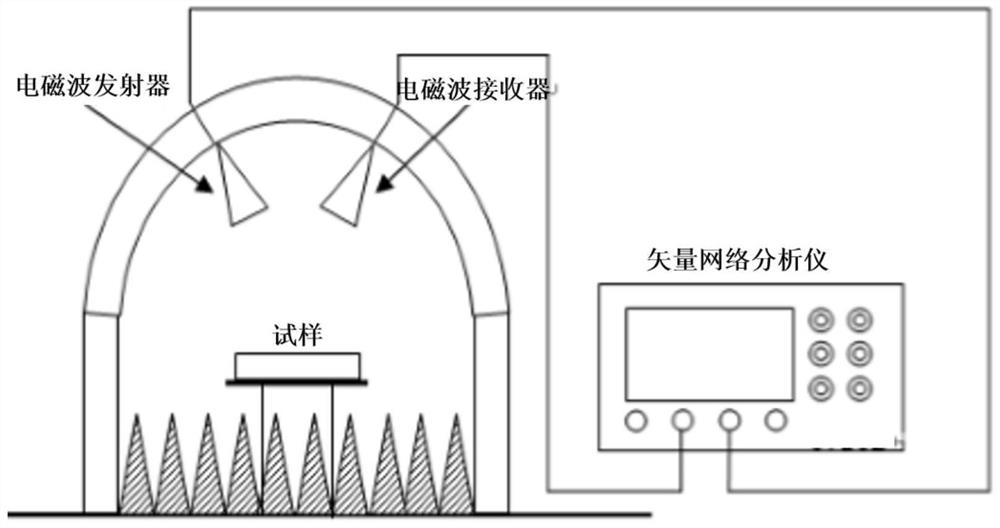

Image

Examples

Embodiment 1

[0032] Cement: P·O 42.5 R ordinary Portland cement, produced by Onoda Cement Plant, 28-day compressive strength 54.3MPa, 28-day flexural strength 8.9MPa, 300 parts.

[0033] NiFe-LDH: nickel-iron layered double hydroxide, pore size 16-23nm, specific surface area 17.85m 2 / g, 3 parts.

[0034] Water reducer: polycarboxylate high-efficiency water reducer, 3 parts.

[0035] Mixing water: Dalian tap water, 100 parts.

[0036] The preparation steps are as follows:

[0037] Accurately weigh the water reducer and add it to the quantitative mixing water, stir for 3 minutes to make the water reducer evenly distributed in the solution, and obtain a mixed aqueous solution. Accurately weighed nickel-iron layered double hydroxide (NiFe-LDH) was added to the aqueous mixing solution, and placed in a 300W ultrasonic environment for ultrasonic treatment for 180s to obtain a uniformly dispersed aqueous mixing solution of NiFe-LDH.

[0038] Accurately weigh the cement according to the propor...

Embodiment 2

[0040] Cement: P·O 42.5 R ordinary Portland cement, produced by Onoda Cement Plant, 28-day compressive strength 54.3MPa, 28-day flexural strength 8.9MPa, 350 parts.

[0041] NiFe-LDH: nickel-iron layered double hydroxide, pore size 16-23nm, specific surface area 17.85m 2 / g, 3.5 parts.

[0042] Water reducer: polycarboxylate high-efficiency water reducer, 3.5 parts.

[0043]Mixing water: Dalian tap water, 120 parts.

[0044] The preparation steps are as follows:

[0045] Accurately weigh the water reducer and add it to the quantitative mixing water, stir for 3 minutes to make the water reducer evenly distributed in the solution, and obtain a mixed aqueous solution. Accurately weighed nickel-iron layered double hydroxide (NiFe-LDH) was added to the aqueous mixing solution, placed in a 300W ultrasonic environment for ultrasonic treatment for 180s, and a uniformly dispersed aqueous mixing solution of NiFe-LDH was obtained.

[0046] Accurately weigh the cement according to the...

Embodiment 3

[0048] Cement: P·O 42.5 R ordinary Portland cement, produced by Onoda Cement Plant, 28-day compressive strength 54.3MPa, 28-day flexural strength 8.9MPa, 400 parts.

[0049] NiFe-LDH: nickel-iron layered double hydroxide, pore size 16-23nm, specific surface area 17.85m 2 / g, 4 parts.

[0050] Water reducer: polycarboxylate high-efficiency water reducer, 4 parts.

[0051] Mixing water: Dalian tap water, 140 parts.

[0052] The preparation steps are as follows:

[0053] Accurately weigh the water reducer and add it to the quantitative mixing water, stir for 3 minutes to make the water reducer evenly distributed in the solution, and obtain a mixed aqueous solution. Accurately weighed nickel-iron layered double hydroxide (NiFe-LDH) was added to the aqueous mixing solution, placed in a 300W ultrasonic environment for ultrasonic treatment for 180s, and a uniformly dispersed aqueous mixing solution of NiFe-LDH was obtained.

[0054] Accurately weigh the cement according to the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com