Sulfonyl biochar flame-retardant wood-plastic plate and production method thereof

A technology of biochar and wood-plastic panels, applied in the field of wood-plastic panels, can solve problems such as casualties, short service life, and obstruction of fire rescue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A sulfonic acid-based biochar flame-retardant wood-plastic board, comprising the following components by weight ratio: 20 parts of bamboo fiber powder processed into a dry state, 90 parts of heavy calcium carbonate, 70 parts of polyvinyl chloride resin powder, 9 parts of PBS resin, 8 parts of hollow ceramic microspheres, 8 parts of ethylene-vinyl acetate copolymer, 5.5 parts of sulfonated carbon, 4 parts of heat stabilizer, 5 parts of foam regulator, 0.6 parts of foaming agent, 0.5 parts of stearic acid parts, PE wax 0.5 parts.

[0027] production method:

[0028] (1) Bamboo wood fiber powder, heavy calcium carbonate, polyvinyl chloride resin powder, PBS resin, hollow ceramic microspheres, ethylene vinyl acetate copolymer, sulfonated carbon, heat stabilizer, foam regulator, foaming agent , stearic acid, and PE wax are mixed and stirred evenly and plasticized according to the above-mentioned proportions by weight to obtain a blend. Among them, the large-volume cold pot...

Embodiment 2

[0033] A sulfonic acid-based biochar flame-retardant wood-plastic board, comprising the following components by weight ratio: 30 parts of bamboo fiber powder processed into a dry state, 110 parts of heavy calcium carbonate, 90 parts of polyvinyl chloride resin powder, 15 parts of PBS resin, 12 parts of hollow ceramic microspheres, 12 parts of ethylene-vinyl acetate copolymer, 7.5 parts of sulfonated carbon, 5 parts of heat stabilizer, 6 parts of foam regulator, 1.2 parts of foaming agent, 1 part of stearic acid 1 part, PE wax 1 part.

[0034] production method:

[0035] (1) Bamboo wood fiber powder, heavy calcium carbonate, polyvinyl chloride resin powder, PBS resin, hollow ceramic microspheres, ethylene vinyl acetate copolymer, sulfonated carbon, heat stabilizer, foam regulator, foaming agent , stearic acid, and PE wax are mixed and stirred evenly and plasticized according to the above-mentioned proportions by weight to obtain a blend.

[0036] (2) Add the blend obtained in...

Embodiment 3

[0040] A sulfonic acid-based biochar flame-retardant wood-plastic board, comprising the following components by weight ratio: 25 parts of bamboo fiber powder processed into a dry state, 100 parts of heavy calcium carbonate, 80 parts of polyvinyl chloride resin powder, 12 parts of PBS resin, 10 parts of hollow ceramic microspheres, 10 parts of ethylene-vinyl acetate copolymer, 6.5 parts of sulfonated carbon, 4.5 parts of heat stabilizer, 5.5 parts of foam regulator, 0.9 parts of foaming agent, 0.8 parts of stearic acid parts, PE wax 0.8 parts.

[0041] production method:

[0042] (1) Bamboo wood fiber powder, heavy calcium carbonate, polyvinyl chloride resin powder, PBS resin, hollow ceramic microspheres, ethylene vinyl acetate copolymer, sulfonated carbon, heat stabilizer, foam regulator, foaming agent , stearic acid, and PE wax are mixed and stirred evenly and plasticized according to the above-mentioned proportions by weight to obtain a blend.

[0043] (2) Add the blend ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

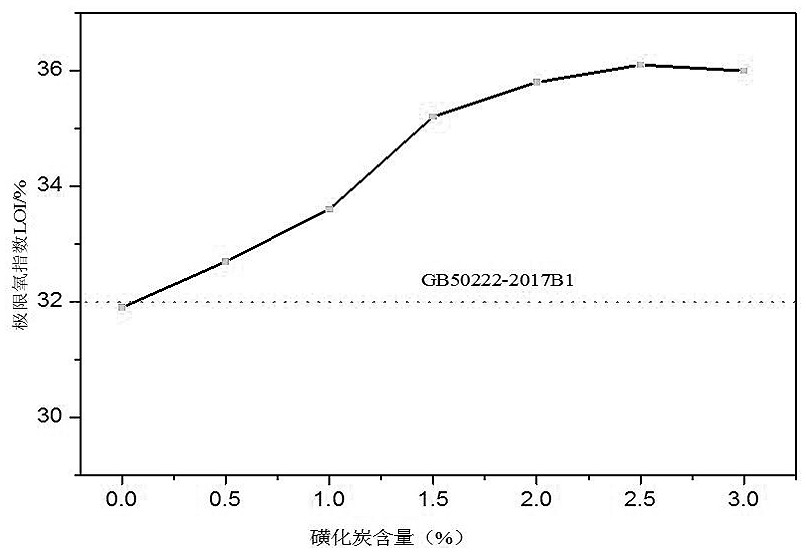

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com