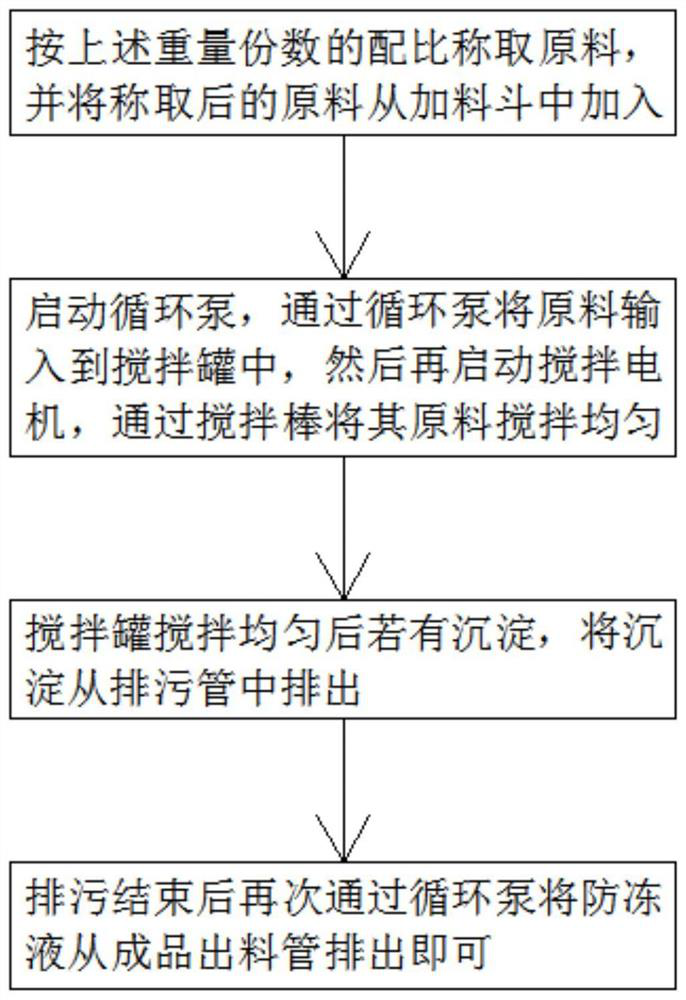

Antifreeze fluid for bulk granular cargo transportation and its preparation process

A technology of cargo transportation and preparation process, applied in other chemical processes, chemical instruments and methods, heat exchange materials, etc., can solve problems such as difficulty in unloading at unloading stations, affecting the normal turnover of railway vehicles, and prone to freezing. Significant moisturizing effect, low price and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

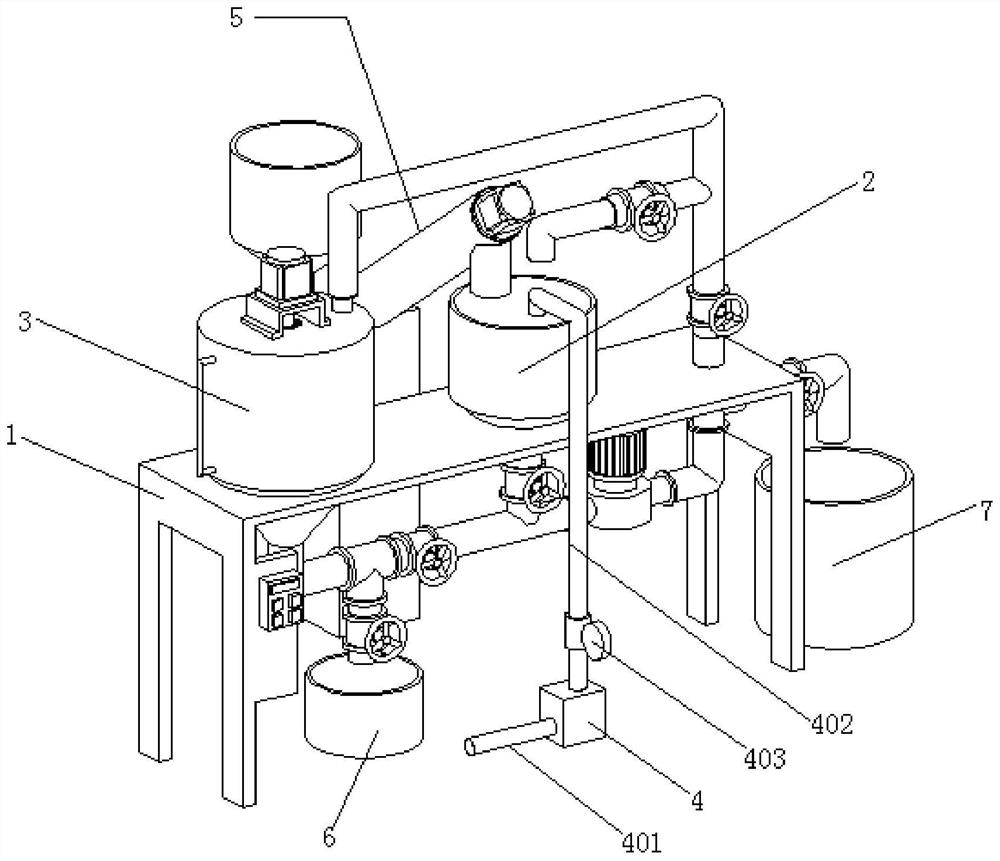

[0066] This embodiment 1 discloses a preparation device for antifreeze used in the transportation of bulk granular goods and the preparation process, refer to the attached figure 2 And attached image 3 , its main structure includes a whole frame 1, a hopper 2 and a mixing tank 3. Specifically refer to the attached Figure 8 , its overall frame 1 includes an upper horizontal plate 101 and two left and right support plates 102, the support plate 102 is connected with a mounting plate 103, the mounting plate 103 is provided with a control panel 100, and the upper surface of the upper horizontal plate 101 is provided with a first installation The round hole 1011 and the second installation round hole 1012 , the feeding hopper 2 is fixedly installed in the first installation hole 1011 , and the mixing tank 3 is fixedly installed in the second installation round hole 1012 .

[0067] Reference attached Figure 5 , attached Figure 6 And attached Figure 7 , a bearing 301 is pr...

Embodiment 2

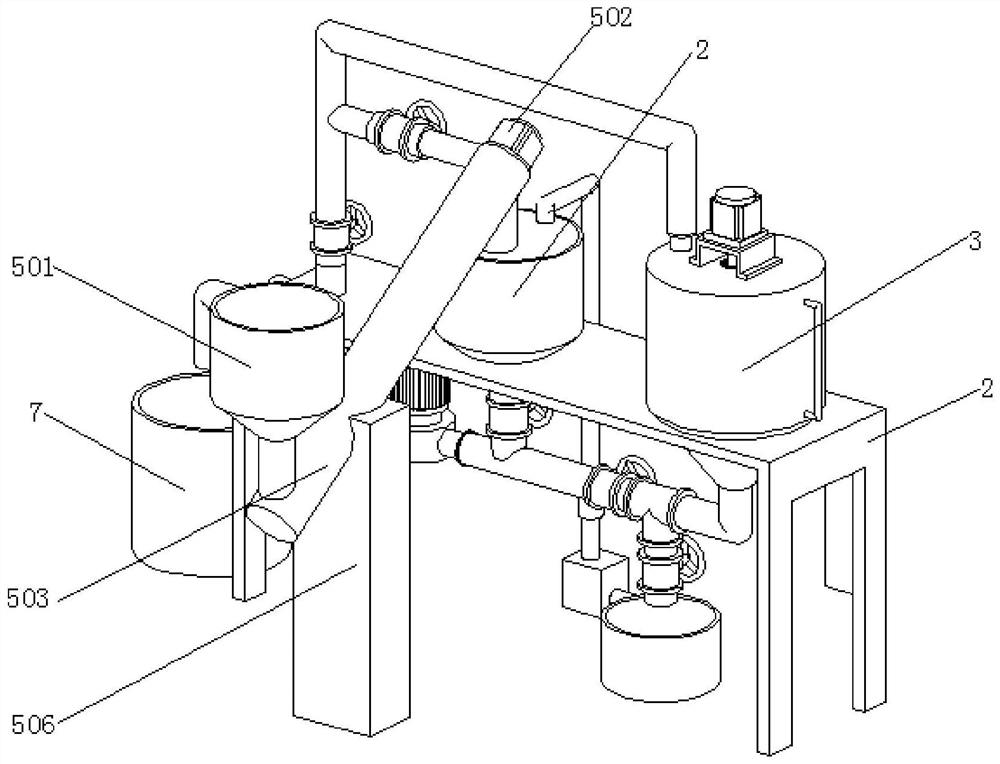

[0073] Example 2 discloses an improved preparation device for antifreeze and preparation process for bulk granular cargo transportation based on Example 1. Its similarities with Example 1 will not be described again. The difference is that :

[0074] The first valve 314, the second valve 316, the third valve 318, the fourth valve 323, the fifth valve 325 and the sixth valve 327 in this embodiment 2 are all electromagnetic valves, and the first valve 314, the second valve 316 , the third valve 318 , the fourth valve 323 , the fifth valve 325 and the sixth valve 327 are electrically connected to the control panel 100 .

[0075] In addition, a liquid level gauge 300 is also provided on the outer surface of the stirring tank 3 .

[0076] At the same time, a dirty liquid receiving bucket 6 is also arranged directly below the sewage pipe 313 .

[0077] Finally, a finished product receiving bucket 7 is also arranged directly below the finished product discharge pipe 322 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com