Urban road surface flaw detection detector and terminal thereof

A detector and urban technology, applied in the field of detection instruments, can solve problems such as data band error, sensor and deflection basin out of contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

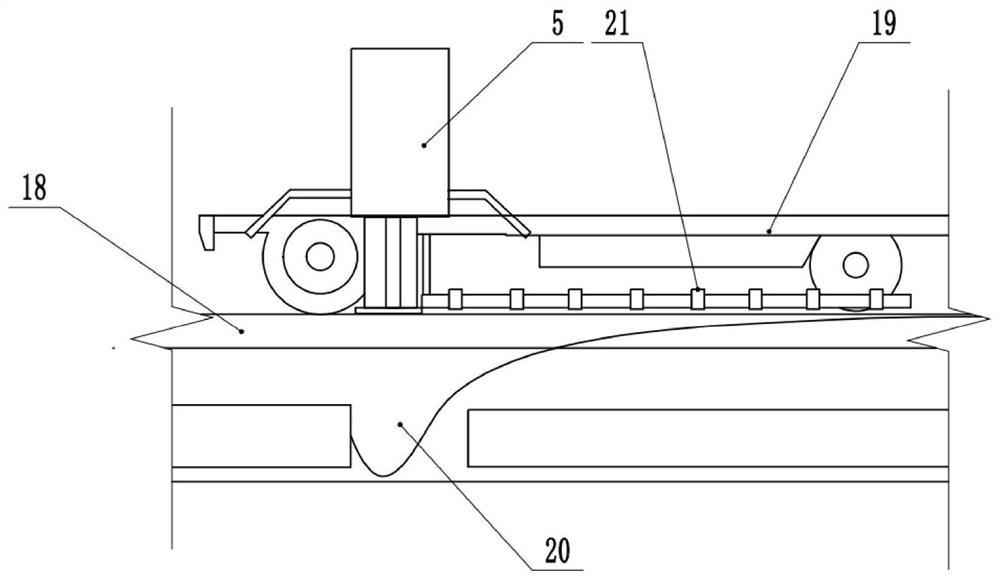

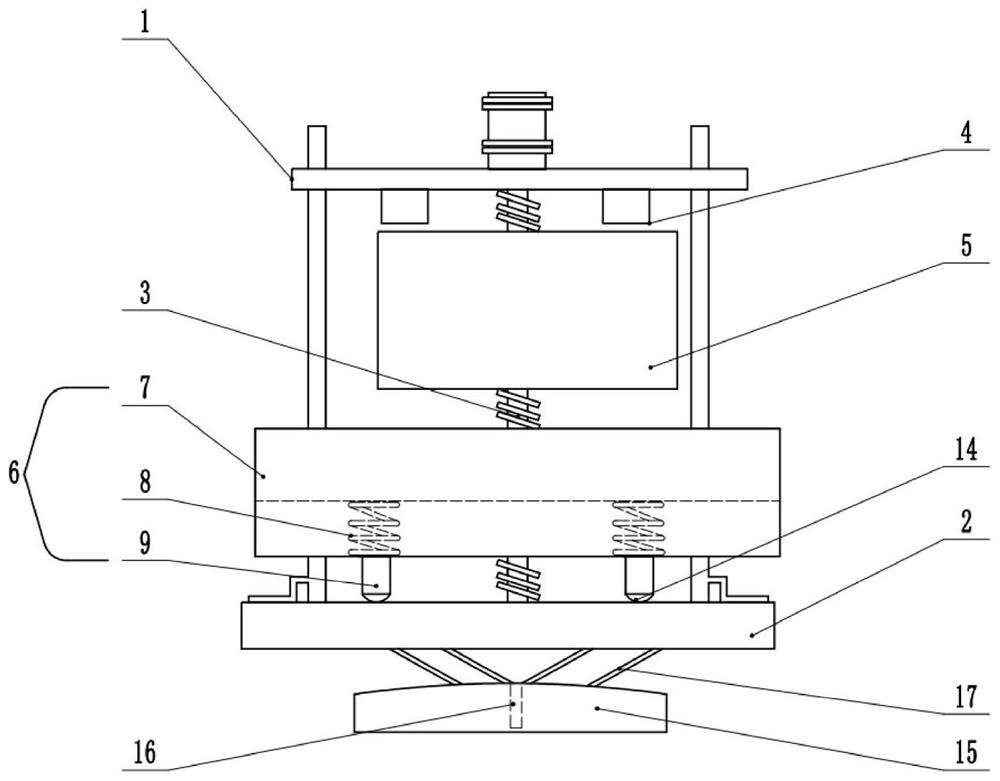

[0035] The embodiment is basically as attached figure 1 And attached figure 2 , as shown: a city road surface flaw detection detector is connected to the tractor 19 of the driving ground 18, including a load-stabilizing platform 1 located above and a bearing platform 2 located below, and a vertical The stroke rod 3 in the direction, the stable load platform 1 has an electromagnet 4 to control the lifting and falling of the gravity hammer 5, the stroke rod 3 wraps the gravity hammer 5, and the surface of the bearing platform 2 is provided with a buffer assembly 6.

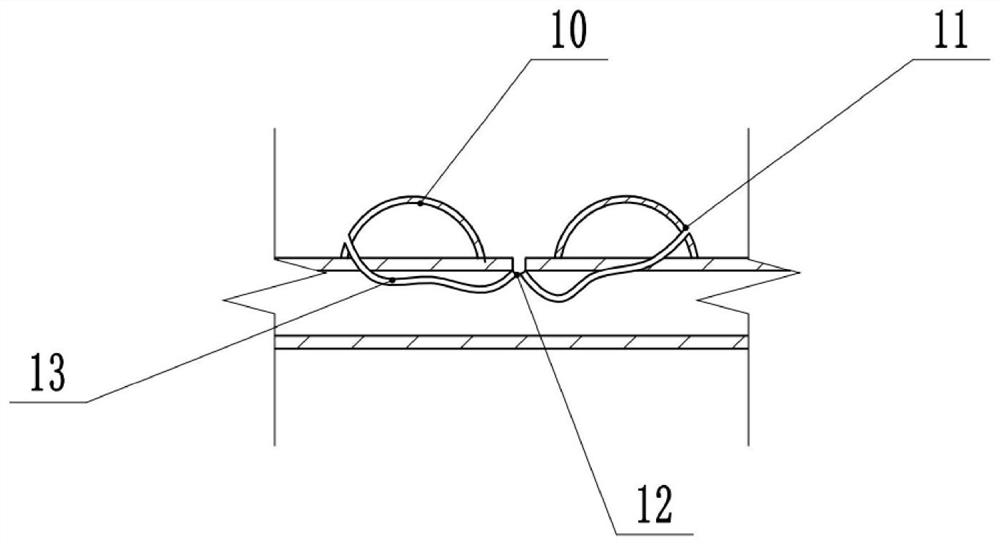

[0036] Please refer to image 3 and Figure 4 , the buffer assembly 6 is divided into rubber layer 7, extension spring layer 8 and point contact layer 9 from top to bottom, extension spring layer 8 has several groups of opposite extension springs, and rubber layer 7 has cylindrical protrusions 10. The protrusions 10 form a rectangular matrix along the center of the rubber layer 7. The protrusions 10 are located ...

Embodiment 2

[0043] The difference between this embodiment and the above-mentioned embodiments is that this embodiment discloses an urban road surface flaw detection detection terminal including a deformation sensor 21, a data processor, a memory, and an output device. The number of deformation sensors 21 is 8, and the deformation sensor The device 21 is connected with a measuring beam, and the deformation sensor 21 is distributed in-line around the first sensor 16, and the data memory is connected in parallel with the memory, the deformation sensor 21, the center sensor and the output device, and the output device includes a display and a printer, and the travel lever 3 Adopt hydraulic rod.

[0044] The specific implementation process is as follows: adjust the mass and height of the gravity hammer 5, and control the weight to be loaded to the fourth-level load, then arrange the measuring points on the road surface, lower the side beams when the measuring points are arranged, so as to distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com