A Piezoelectric Synchronously Tuned ECDL Laser Based on Sector Ring Structure

A synchronous tuning and fan-ring technology, applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as complexity, not compact structure, unstable output wavelength of lasers, and broadening of line width, so as to optimize vibration resistance and improve reliability performance, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The technical solution of the present invention will be clearly and completely described through examples below.

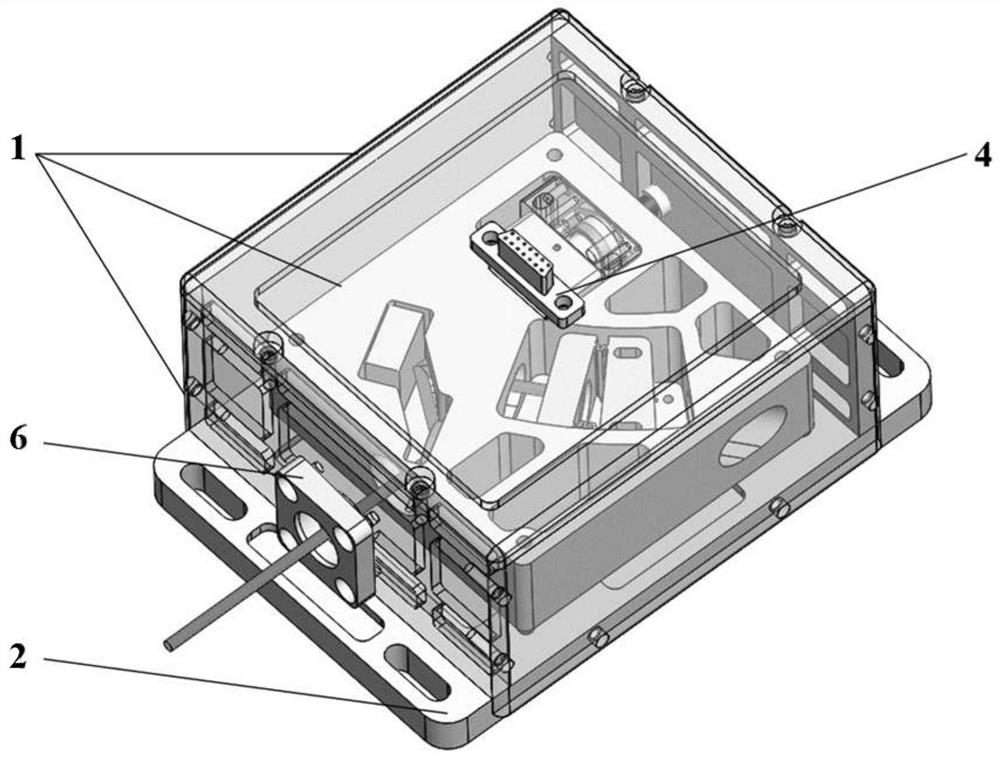

[0029] figure 1 A schematic diagram of the overall appearance of the ECDL laser described in the present invention is shown.

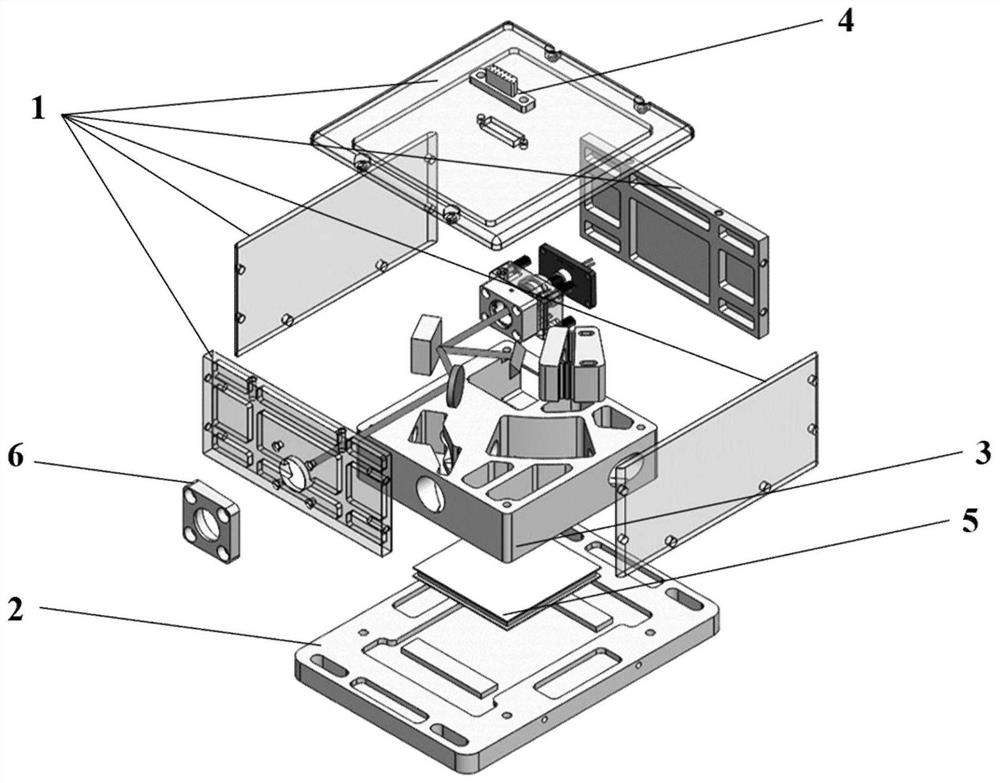

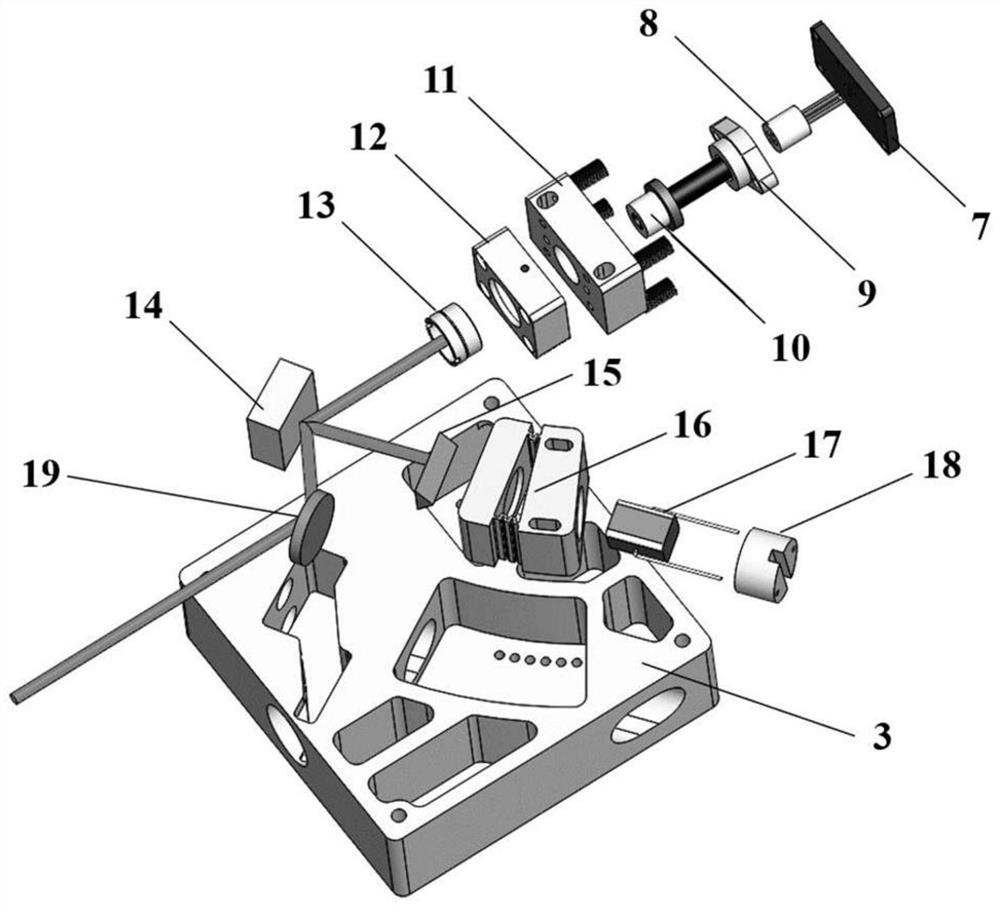

[0030] figure 2 The exploded disassembly diagram of the ECDL laser according to the present invention is shown: including the laser shell 1, the laser outer bottom plate 2, the fan ring guide rail bottom plate 3, the controller interface 4, the temperature control ceramic 5, the output window 6, thermistor, and the current interface Board 7, laser diode pin socket 8, laser diode pressure ring 9, laser diode 10, laser diode holder 11, collimator lens holder 12, collimator lens 13, reflective grating 14, right-angle prism 15, fan ring tuning bracket 16. Piezoelectric ceramics 17, piezoelectric ceramic mounting sleeves 18, high reflection mirrors 19;

[0031] The laser housing 1 includes a front plate, a rear plate, two side plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com