Industrial wastewater advanced total nitrogen removal treatment process and denitrification device thereof

A technology for industrial wastewater and nitrogen treatment, applied in the direction of aerobic process treatment, special compound water treatment, biological water/sewage treatment, etc., can solve the problem that it is difficult to meet the advanced treatment requirements, the removal of total nitrogen is not considered, and the discharge standard cannot be met and other problems, to achieve the effect of improving the total nitrogen removal effect, high degree of automation, and reducing the addition of carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

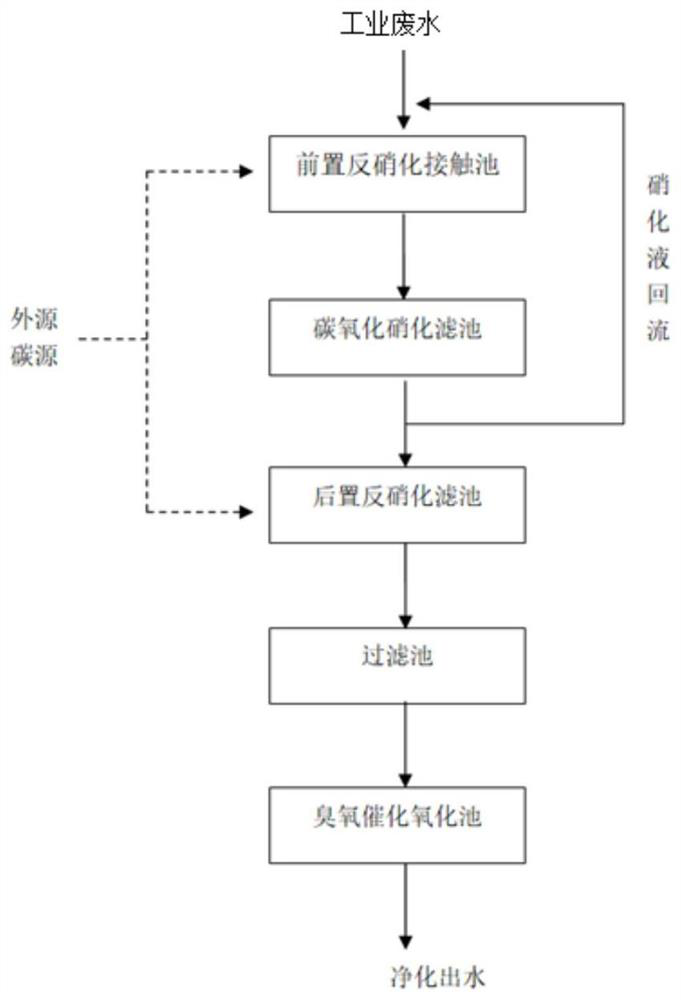

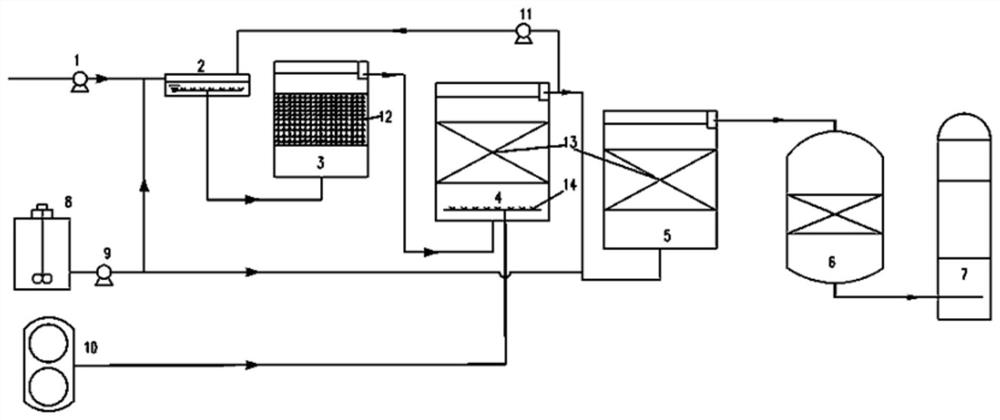

[0043] Embodiment 1: refer to figure 1 , the present invention provides a kind of deep total nitrogen removal treatment process of industrial wastewater, comprising the following steps:

[0044] 1) The industrial wastewater enters the pre-denitrification contact tank 3 after passing through the mixer 2. The top of the pre-denitrification contact tank 3 is provided with bamboo silk filler. The pool needs to distribute water evenly, and at the same time, a curtain-type biological composite filler is installed inside the pool.

[0045] In step 1), when the organic content of industrial wastewater and the concentration of nitrate nitrogen are high, the concentration of nitrate nitrogen is greater than 50mg / L, if the ratio of BOD5 (biochemical oxygen demand five days) to TN (total nitrogen content) is greater than 4 , it can be considered that the composition of incoming water is suitable for the growth of denitrifying bacteria. No carbon source is added to the pre-denitrification ...

Embodiment 2

[0057] Embodiment 2: refer to figure 1 , the present invention provides a kind of deep total nitrogen removal treatment process of industrial wastewater, comprising the following steps:

[0058] 1) Industrial wastewater enters the pre-denitrification contact tank after passing through the mixer. Bamboo silk filler is arranged on the top of the pre-denitrification contact tank, and the water needs to be evenly distributed in the pool. Removal of total nitrogen to obtain pre-reaction effluent. The adaptation environment of the pre-denitrification tank in step 1) is pH=7, total nitrogen is 124 mg / L, and the residence time is 5 hours.

[0059] In step 1), when the organic content of industrial wastewater and the concentration of nitrate nitrogen are high, the concentration of nitrate nitrogen is greater than 50 mg / L, and if the ratio of BOD5 to TN is greater than 4, it can be considered that the composition of incoming water is suitable for the growth of denitrifying bacteria , ...

Embodiment 3

[0070] Embodiment 3: refer to figure 1 , the present invention provides a kind of deep total nitrogen removal treatment process of industrial wastewater, comprising the following steps:

[0071] 1) The industrial wastewater enters the pre-denitrification contact pool after passing through the mixer. The pool needs to distribute water evenly. At the same time, a suspended biological composite filler is installed inside the pool. The industrial wastewater undergoes a preliminary total nitrogen removal reaction to obtain pre-reaction effluent. In step 1), the adaptation environment of the pre-denitrification tank is pH 9, the total nitrogen is 151 mg / L, and the residence time is 6 hours.

[0072] 2) The pre-reaction effluent in step 1) enters the carbon oxidation and nitrification filter tank, the tank is equipped with an aeration device, and the filter tank is provided with a biological ceramsite filler layer, and microbial flora is attached to the biological ceramsite filler la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com