Olefin polymerization catalyst component, olefin polymerization catalyst and application

A technology for olefin polymerization and catalysts, which is applied in olefin polymerization catalyst components and olefin polymerization catalysts and application fields, can solve the problems of poor copolymerization performance and low activity, and achieve the effects of improving copolymerization performance, increasing polymerization activity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

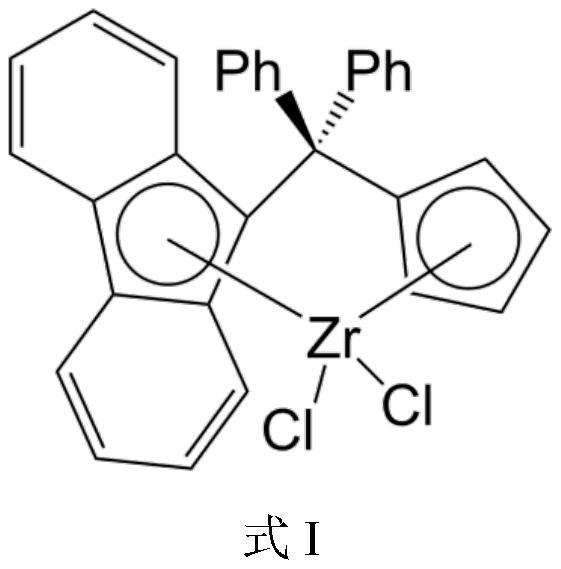

[0052] The preparation of the catalyst component was carried out in an inert gas-protected glove box at room temperature, and 20 μmol of dibenzylidene (cyclopentadienyl) (9-fluorenyl) zirconium dichloride powder was weighed and placed in a glass bottle , 0.3 mL of a hexane solution of triisobutylaluminum with a concentration of 0.4 mol / L was added dropwise, and then 11 mL of toluene was added, and stirred for about 5 min to obtain an orange-red catalyst component solution.

[0053] The reactor is a 500mL reactor with a stirrer. Before the reaction, carry out conventional dehydration and deoxidation treatment, and pass through polymer grade ethylene for replacement 3 times. First add 300mL of refined hexane to the reaction kettle, then add 8mL of a hexane solution of triisobutylaluminum with a concentration of 0.4mol / L, 11mL of refined hexene, 8mL of the above-mentioned catalyst component solution, and 8mL of a concentration of 2mmol / L toluene solution of trityl tetrakis (pen...

Embodiment 2

[0055] Weigh 23 μmol of dibenzylidene (cyclopentadienyl) (9-fluorenyl) zirconium dichloride powder and place it in a glass bottle, add 12 mL of toluene, and then dropwise add 2.3 mL of Tris The hexane solution of isobutylaluminum was stirred for about 5 minutes to obtain an orange-red catalyst component solution.

[0056] Other polymerization conditions were the same as in Example 1, 8.5 mL of the catalyst solution was added, the reactor temperature was 80° C., and the reaction time was 10 min. Obtained polymer 11.7g, melt flow rate is 127g / 10min, density is 0.881g / cm 3 , the hexene content is 25%, and the polymerization activity is 5.14×10 5 g·g -1 (Zr) h -1 .

Embodiment 3

[0058] Other conditions are the same as in Example 2, except that the catalyst component solution is 6.2 mL during olefin polymerization, and the hexane solution of triisobutylaluminum and the toluene solution of trityl tetrakis (pentafluorophenyl) borate are added in different amounts. is 5mL. The reaction time was 18min, and 8.7g of polymer was obtained, the melt flow rate was 0.7g / 10min, and the density was 0.9g / cm 3 , the hexene content is 14%, and the polymerization activity is 3.19×10 5 g·g -1 (Zr) h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com