Low-temperature impact-resistant enhanced AXS/PBAT alloy and preparation method and application thereof

An alloy, low temperature technology, applied in the field of polymer material modification, can solve the problems of poor low temperature impact resistance, and achieve the effect of improving low temperature impact resistance and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~22

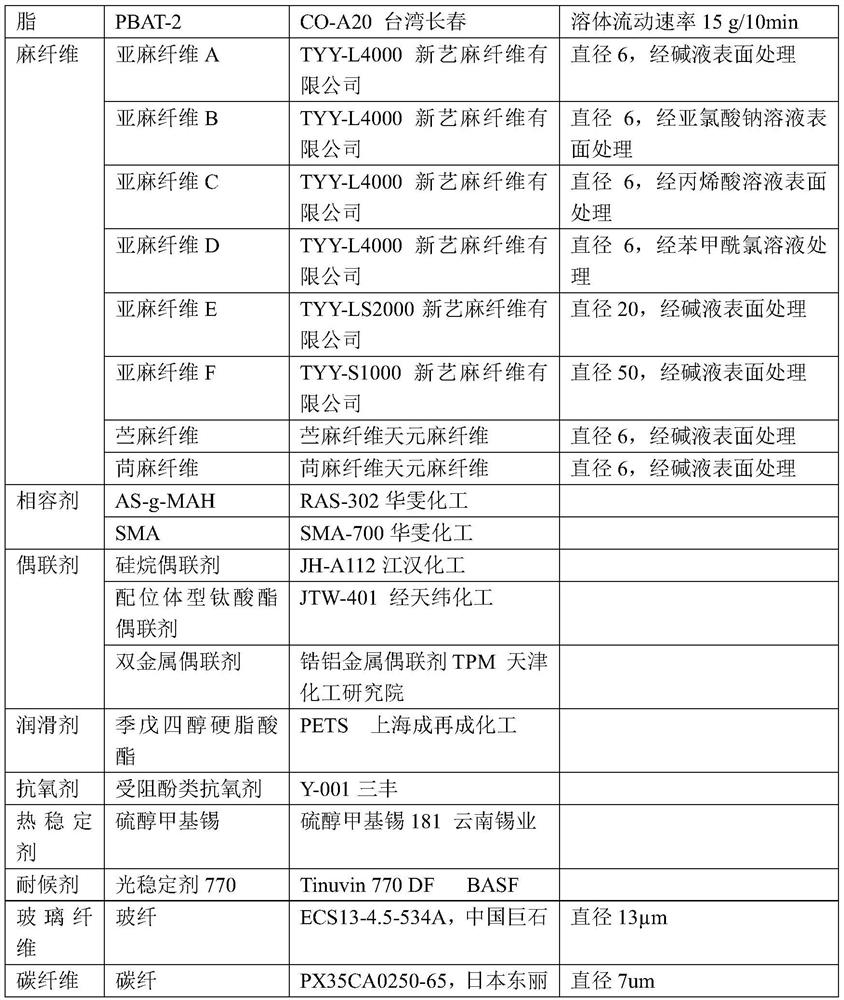

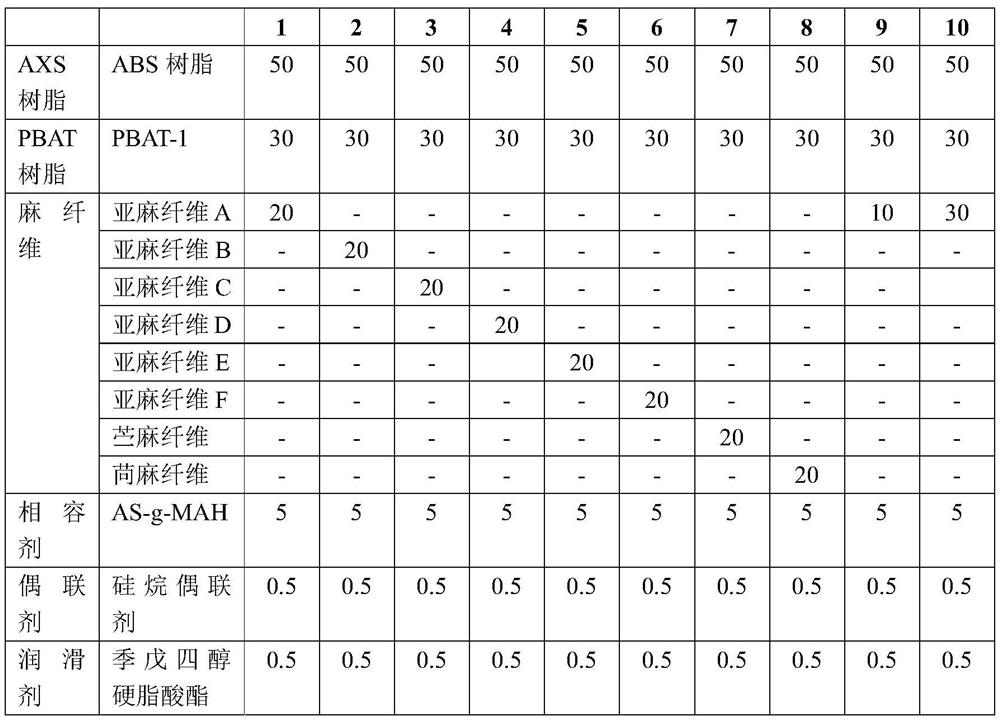

[0057] The content of each component in the AXS / PBAT alloys of Examples 1-22 is shown in Table 1.

[0058] Its preparation method is:

[0059] According to Table 1, AXS resin, PBAT resin, compatibilizer, coupling agent, lubricant, and other auxiliary agents are mixed and added to the main feeding port of the twin-screw extruder, and the hemp fiber is added to the main feed port of the twin-screw extruder. The side feeding port is melted and granulated to obtain a reinforced AXS / PBAT alloy with low temperature impact resistance.

[0060] The feeding speed of the twin-screw extruder is 200-350rpm; the temperature of each section of the twin-screw extruder from the feeding port to the machine head is 120-160°C in the first zone, 170-210°C in the second zone, and 170-210°C in the third zone. 170-210°C, 170-210°C in the fourth zone, 170-210°C in the fifth zone, 190-230°C die temperature, 100-500r / min main machine speed, vacuum degree ≤0.1MPa.

[0061] The component content (weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com