Water-based matte oil-resistant synthetic leather and preparation method thereof

A technology for preventing oil pollution and synthetic leather, applied in the field of synthetic leather, can solve the problems of being unfriendly to the environment, endangering human health, not having oil pollution resistance, etc., and achieving a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The water-based matte oil-stain-resistant synthetic leather provided by the present embodiment includes a base cloth layer, a solvent-free adhesive layer, a dry-process PU surface layer and an oil-stain-resistant surface treatment layer arranged in sequence, wherein,

[0033] In this example, the base fabric layer uses 0.85 double black gray imitation cotton wool.

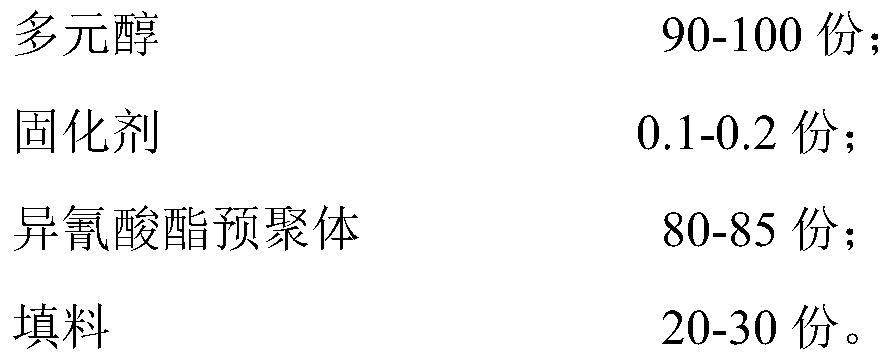

[0034] In this example, the raw material composition of the solvent-free adhesive layer is: 100 parts of BASF's 2500C-A polyol, 30 parts of calcium carbonate, 0.2 parts of BASF's 95C-CC curing agent and 85 parts of BASF's 2500C-B isocyanate prepolymer.

[0035] In this example, the raw material composition of the dry PU surface layer is: 100 parts of water-based polyurethane fabric from Zhejiang Huafeng Synthetic Resin Co., Ltd., 0.15 parts of thickener, 1.5 parts of wetting and leveling agent and 13 parts of color paste.

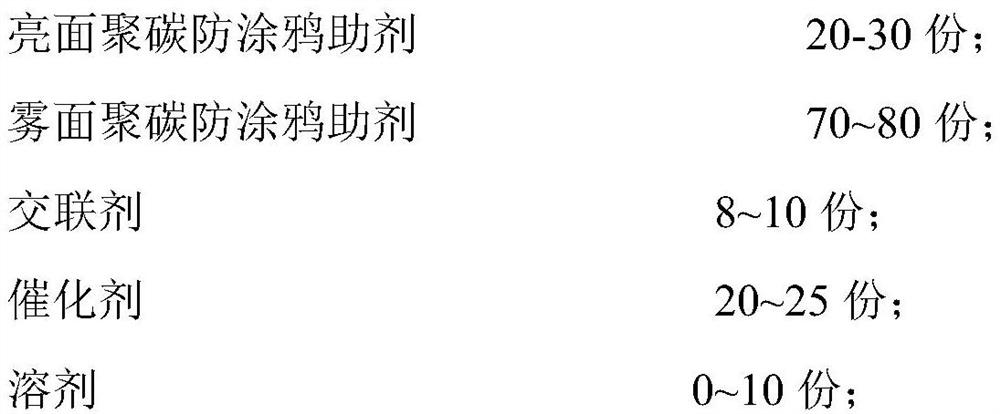

[0036] In this example, the raw material formula of the anti-oil stain surface treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com