Drag-reducing and wear-resisting drill string protector

A technology for protectors and drill strings, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., and can solve the impact of drill string and casing safety and borehole life, the reduction of crush strength, internal pressure resistance, and drill string Excessive friction and wear with the casing, etc., to achieve the effects of flexible and convenient loading and unloading, reduced frictional resistance, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

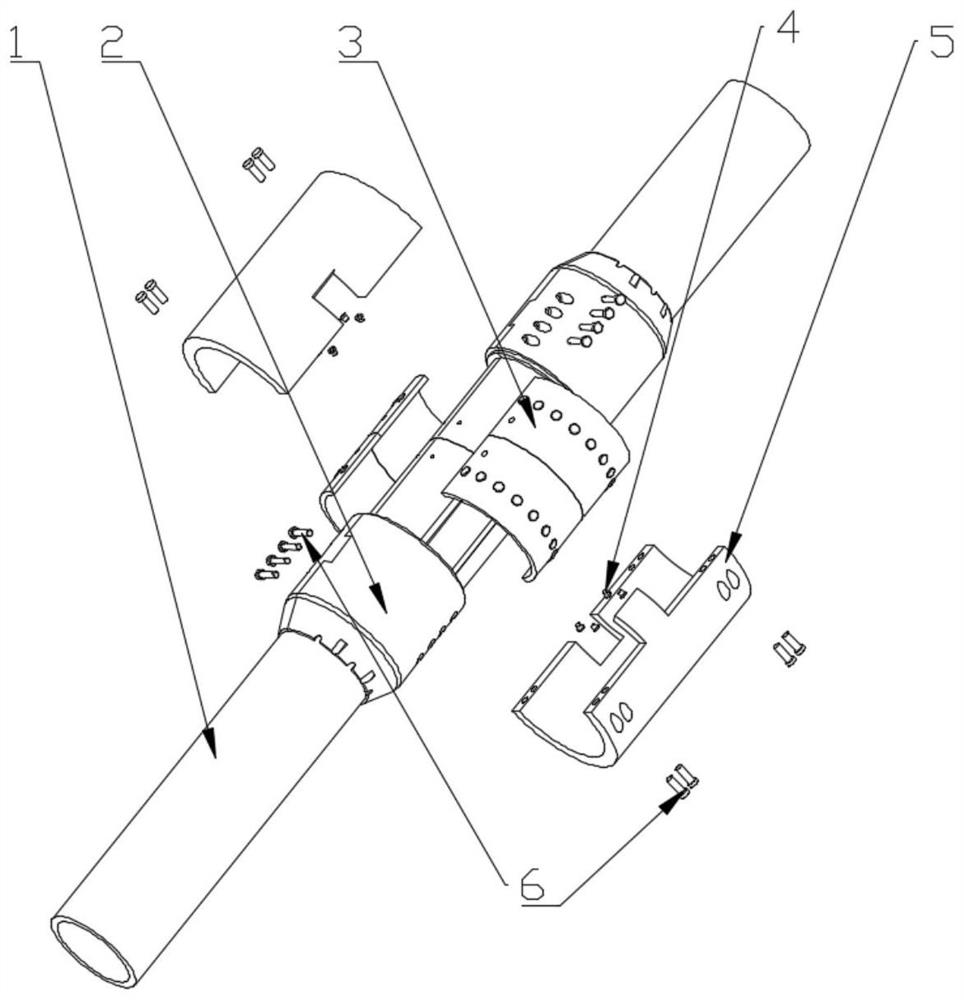

[0013] figure 1 A schematic diagram of installation of a drag-reducing and anti-wear drill string protector according to an embodiment of the present invention is schematically shown. The drag-reducing and anti-wear drill string protector according to the invention is especially suitable for extended-reach wells and horizontal wells.

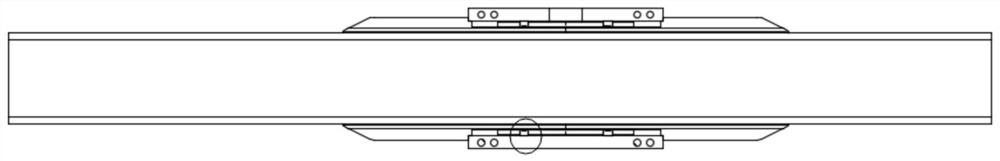

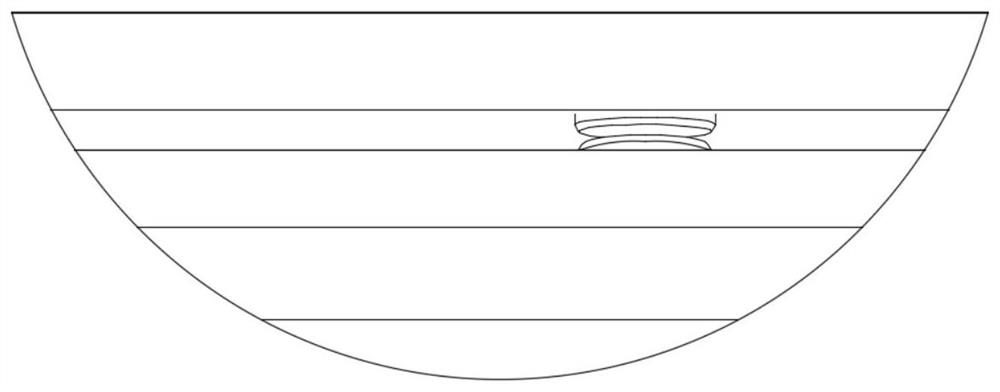

[0014] see figure 1 , the drag-reducing and anti-wear drill string protector of this example is characterized in that: the drag-reducing and anti-wear drill string protector is sequentially composed of a shaft sleeve (2), a sliding sleeve (3), and a clamping bolt (4 ), wear sleeves (5) and locking bolts (6), the drag reducing and anti-wear drill string protector contains bushings (2), consisting of 2 semicircular bushings with complementary interlocking profiles, sliding The sleeve (3) contains at least 2 circumferential arc-shaped fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com