Multi-stage multiphase mixture pump visualization device and method with an undisturbed inlet

A non-disturbance, inlet technology, applied in the components of pumping devices for elastic fluids, radial flow pumps, pumps for special fluids, etc., can solve the problem of lack of qualitative and quantitative transient effects, and achieve easy and frequent disassembly and assembly. Replaceable, reproducible, reduces flow resistance and turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

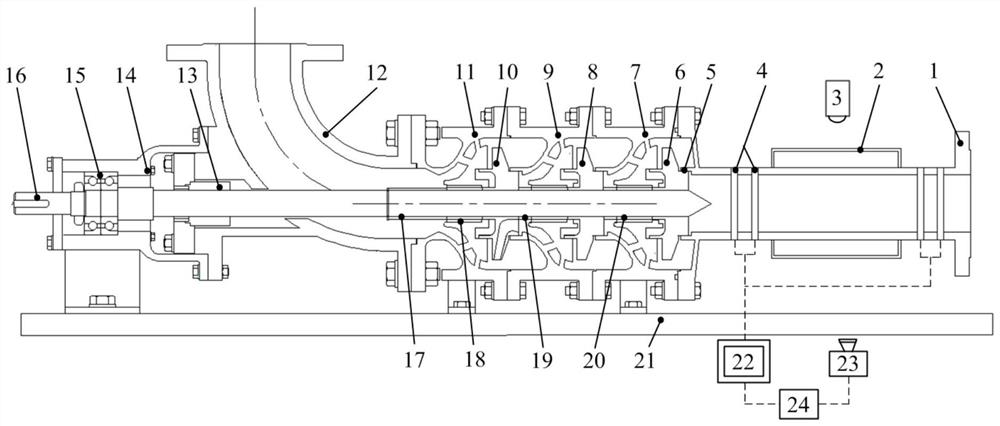

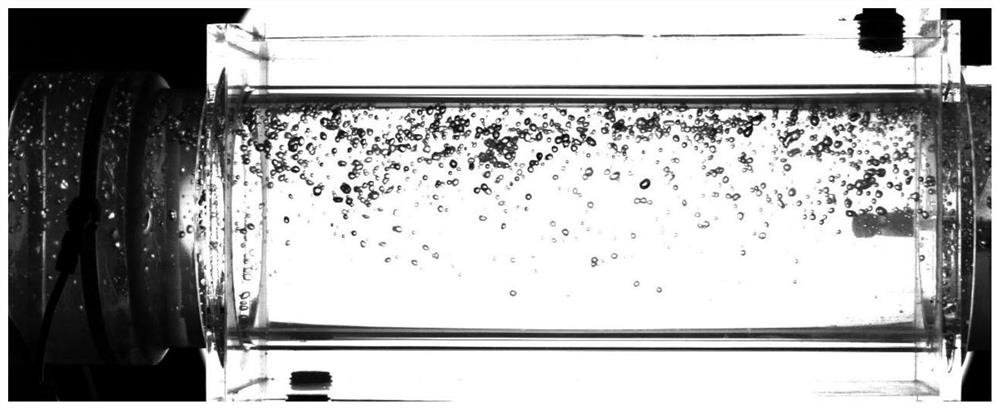

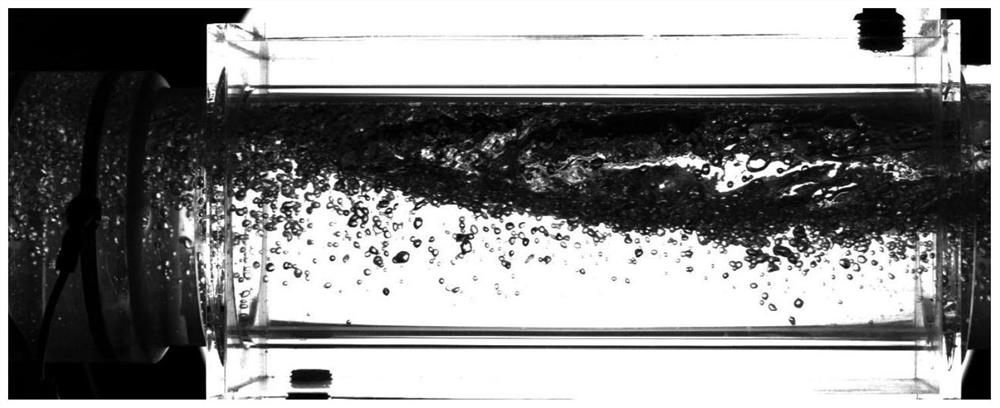

[0029] Example 1: Visual capture of inlet bubbly flow and slug flow interface

[0030] This embodiment will describe the visual capture method of phase interface characteristics of different inlet gas-liquid flow patterns, and describe the method in detail. The specific implementation is as follows:

Embodiment 2

[0033] Example 2: Dynamic change of liquid holdup at the inlet of bubbly flow and slug flow

[0034] In the above example, the method for obtaining the gas-liquid phase distribution parameters of different flow patterns is given and the distribution of the phase interface is described. In this example, the inlet phase parameters of the multi-stage multi-phase mixed pump under different flow patterns are obtained by using a conductivity probe. Transient change characteristics, the specific implementation is as follows:

[0035] Example conditions: the water flow rate at the inlet of the multi-stage multi-phase mixed pump is 25m 3 / h, the volumetric gas fractions are 5.1% and 20.6%, respectively, the rotational speed is 3500rpm, and the visualized inlet pressure is 0.25MPa. First, connect two pairs of double-ring probes arranged on both sides of the optical path compensation water jacket to the processing and acquisition module, and connect the synchronizer. The inlet and outle...

Embodiment 3

[0037] Example 3: Pressure change along the flow direction of a multi-stage mixed transport pump under a bubble-like flow inlet

[0038] The proposed multi-stage multi-phase mixed pump is connected by interstage flanges, which is easy to disassemble, and it is also convenient to arrange pressure measuring points to obtain pressure characteristics at different positions along the flow direction. The conditions of the example above were adopted.

[0039] Example conditions: the water flow rate at the inlet of the multi-stage multi-phase mixed pump is 25m 3 / h, the volumetric gas fraction is 5.1%, the rotational speed is 3500rpm, and the visualized inlet pressure is 0.25MPa. The pressure measuring points are arranged between the stages of the multi-stage multi-phase mixed pump, and the measuring points are respectively: the inlet of the mixed pump, the inlet of the impeller, the outlet of the diffuser, the cavity and the outlet of the mixed pump, etc. Among them, the inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com