Air conditioner

A technology for air conditioners and air conditioner loads, applied in refrigerators, high-efficiency regulation technology, AC motor control, etc., and can solve problems such as taking into account the factors of refrigerant increase, large compressor vibration, and small current value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below according to the preferred embodiment shown in the accompanying drawings.

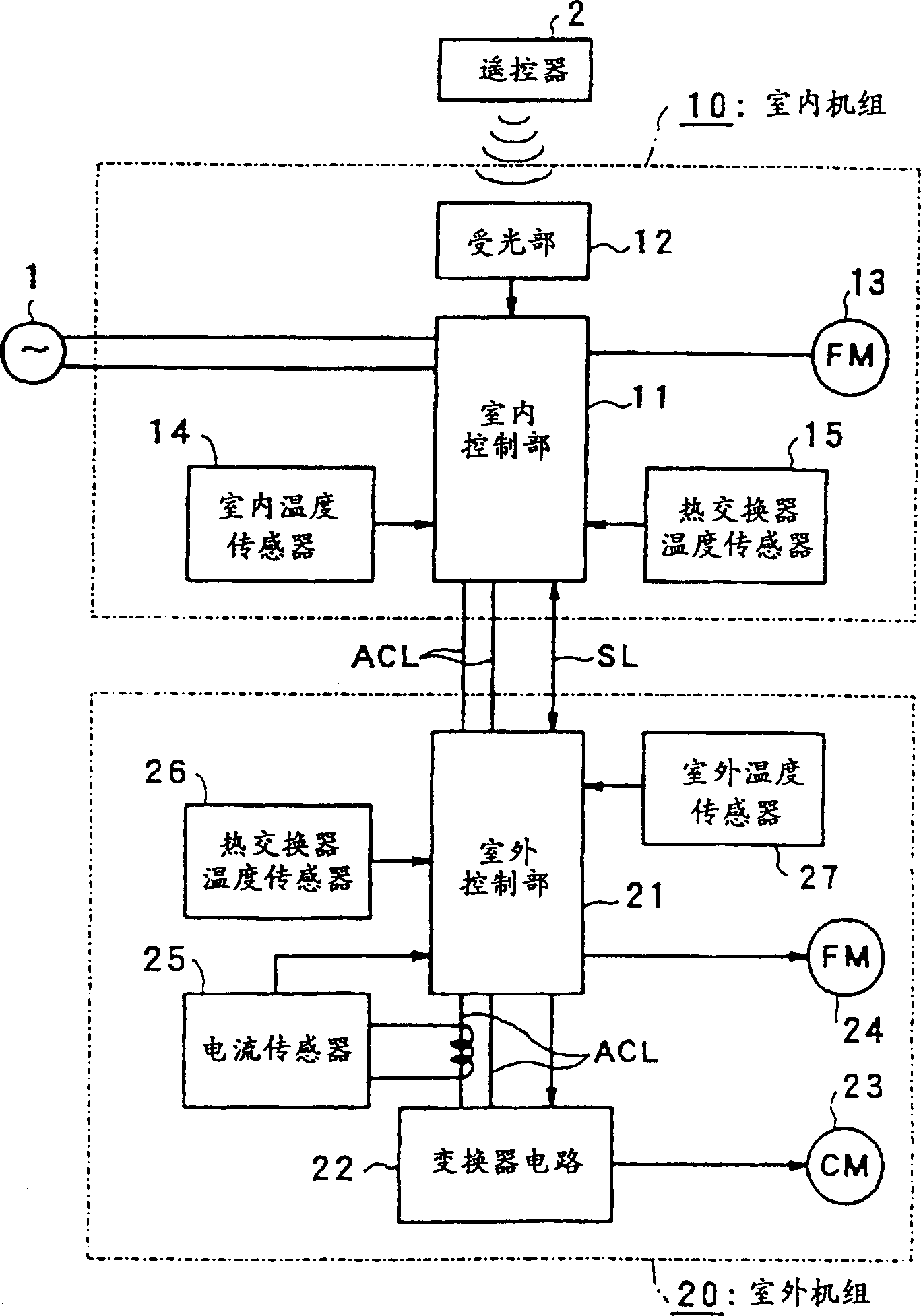

[0033] figure 1It is a block diagram showing the schematic configuration of the control system according to the first embodiment of the present invention. In this figure, 1 is a single-phase AC power supply, and 2 is a remote control device. The indoor unit 10 is connected to the single-phase AC power supply 1 , and an infrared control signal is sent from the remote control device 2 . The indoor unit 10 includes: an indoor control unit 11 including a microcomputer as a control means, receives the signal from the remote control device 2 and adds the signal to the light receiving unit 12 on the indoor control unit 11, and the indoor control unit 11 controls the speed. The controlled indoor fan motor 13 detects the indoor temperature and supplies it to the indoor temperature sensor 14 of the indoor control unit 11 , and detects the indoor h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com