LOHC fuel cell power generation system and method

A fuel cell and power generation system technology, applied in the field of hydrogen energy, can solve problems such as temperature mismatch, increase in heat transfer coefficient equipment size, narrow reaction temperature window, etc., to reduce dehydrogenation reaction consumption, improve energy utilization rate, and reduce disadvantages effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail through specific embodiments below in conjunction with schematic diagrams.

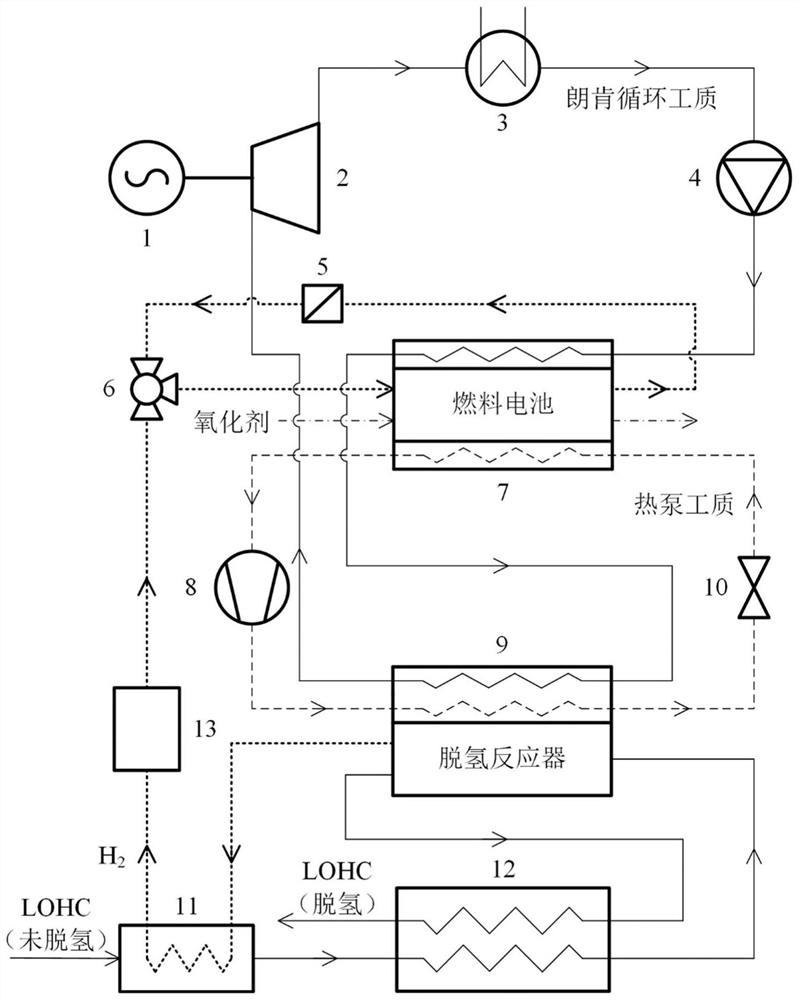

[0036] like figure 1 As shown, the present invention provides a LOHC fuel cell power generation system, which is composed of four subsystems: fuel cell, high temperature heat pump, LOHC dehydrogenation and Rankine cycle. Among them, the fuel cell subsystem, the H 2 The chemical energy is converted into electrical energy; the high-temperature heat pump subsystem converts the low-temperature thermal energy of the fuel cell into high-temperature thermal energy; the LOHC dehydrogenation subsystem utilizes high-temperature thermal energy to realize LOHC dehydrogenation; the Rankine cycle subsystem converts the residual thermal energy of the system into electrical energy.

[0037] The fuel cell subsystem consists of dehumidifier 5, mixer 6, fuel cell 7, H 2 The buffer tank 13 and related connecting pipelines, bypass loops, valves, temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com