Method for improving discoloration and gelation of solid electrolyte, preparation method of solid electrolyte, and solid electrolyte

A solid electrolyte and gel technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of prolonging the overall production time, complicated process, and long processing time, and achieve the solution of decreased ion conductivity, simple and effective process, The effect of consistency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

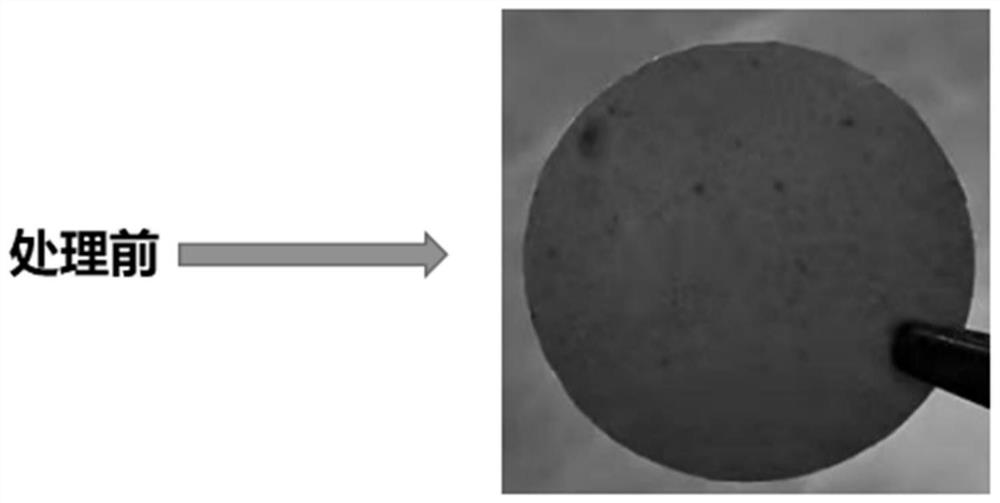

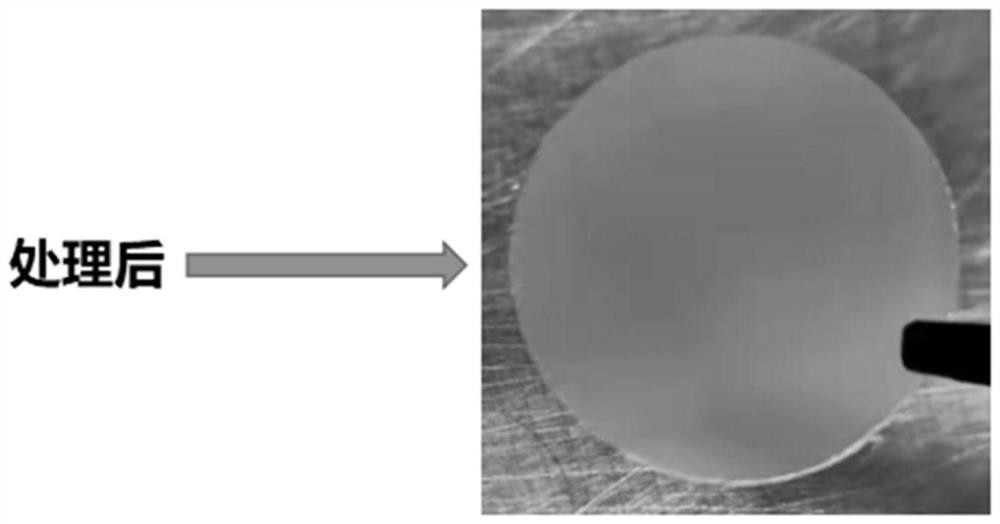

[0057] This embodiment provides a method for improving the discoloration and gelation of solid electrolyte solid electrolyte, and the method includes:

[0058] 1. Take 500μL, 1mol / L of hydrochloric acid and add it to 50mL of alcohol, dilute it into 0.01mol / L acid solution, and then add 5g LLZTO to the solution. The quality of the acidic substance in the acid solution is the residual alkali on the surface of the inorganic solid electrolyte. 1.03 times the mass of , and sonicated for 10 min. After sonication, the alcohol and oxide electrolytes were separated using suction filtration. Then, the treated LLZTO was obtained by drying at 100 °C for 12 h.

[0059] 2. Add 0.1 g of the treated LLZTO powder to 8 mL of NMP (N-methylpyrrolidone) and sonicate for 10 min to ensure that the LLZTO powder is uniformly dispersed in NMP.

[0060] 3. Add 0.33g LiTSI and 1g PVDF to the above LLZTO / NMP dispersion, and stir magnetically for 12h to ensure that the above materials form a uniform glue...

Embodiment 2

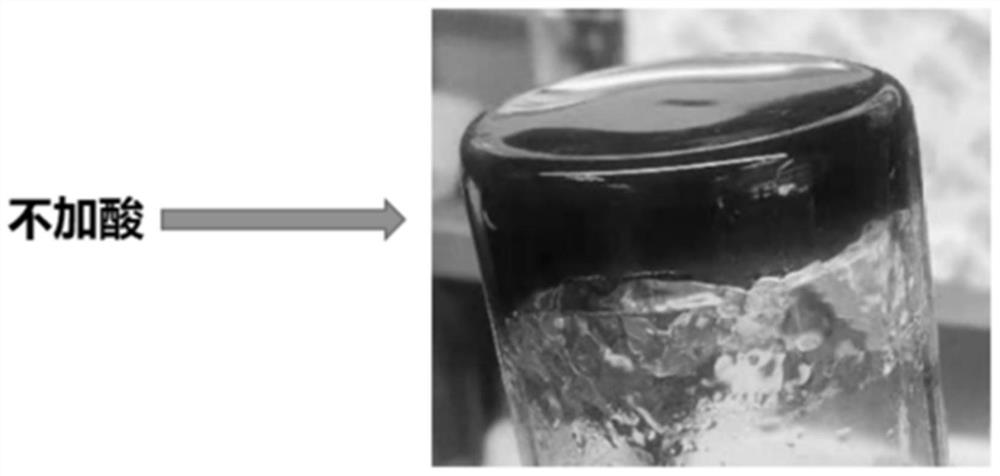

[0066] This embodiment provides a method for improving the discoloration and gelation of solid electrolyte solid electrolyte, and the method includes:

[0067] 1. Take 5 μL of hydrochloric acid (1 mol / L), add 0.1 g of LLZTO to 8 mL of NMP solvent, the mass of the acidic substance is 1.04 times the mass of the residual alkali on the surface of the inorganic solid electrolyte, ultrasonically disperse it for 10 minutes, and simultaneously remove the residual alkali by an acid-base reaction.

[0068] 2. Add 0.33g LiTFSI and 1g PVDF to the above LLZTO / NMP dispersion, and stir magnetically for 12h to ensure that the above materials form a uniform glue.

[0069] 3. Use a doctor blade to coat the above glue solution on the surface of the glass plate with a thickness of 400 μm. After the blade coating is completed, the glass plate is placed in a vacuum drying oven, dried at 60° C. for 12 h, and the NMP solvent is removed to obtain an organic / inorganic composite electrolyte.

[0070] T...

Embodiment 3

[0074] The difference from Example 1 is that the volume of alcohol used in Step 1 is 20 mL, and under this condition, the concentration of the acid solution is 0.025 mol / L, and the difference between the quality of the acidic substance in the acid solution and the residual alkali on the surface of the inorganic solid electrolyte is 0.025 mol / L. The ratio is the same as in Example 1.

[0075] table 3

[0076]

[0077] Note: The numbers in the table represent parallel experiments under the conditions of Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com