Odor purification device

A technology for purifying device and odor, which can be used in combination devices, air quality improvement, chemical instruments and methods, etc., and can solve problems such as difficult governance, air quality impact, and artificial work affecting the surrounding environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

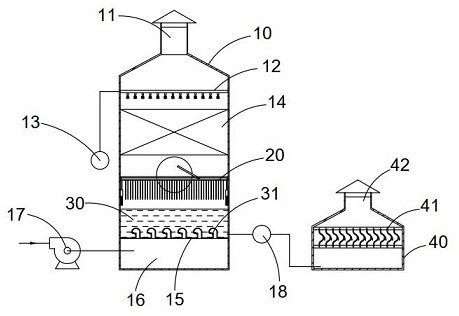

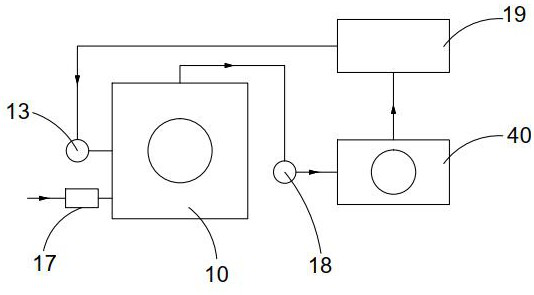

[0045] See attached Figure 1-9 Shown, a kind of odor purifying device comprises:

[0046] The first box body 10, the inner bottom of the first box body 10 is separated by the first partition plate 15 to form an air intake chamber 16, the first box body 10 is provided with a second pump body 17, and the second pump body 17 passes through the pipe body and The air intake chamber 16 is in communication, the upper part of the first partition 15 has an air intake pipe body 31 communicating with the bottom air intake chamber 16, and the upper part of the first box body 10 is connected with a first exhaust pipe 11,

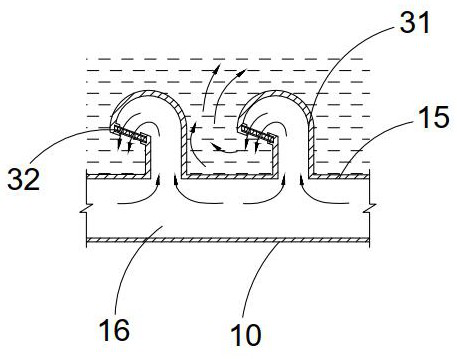

[0047] The bottom of the first box body 10 on the top of the first dividing plate 15 is placed with liquid to form the washing layer 30, and the liquid level of the washing layer 30 is higher than the intake pipe body 31,

[0048] Wherein, the air inlet pipe body 31 air outlet ends are bent and set, the air inlet pipe body 31 air outlet direction is set toward the firs...

Embodiment 2

[0069] The further optimization scheme of present embodiment on the basis of embodiment 1 is: see appendix Figure 10-12 As shown, the water discharged in the first tank 10 is sent to the waste water treatment tank 40 through the third pump body 18, the upper part of the waste water treatment tank 40 is provided with a second exhaust pipe 42, and the upper part of the waste water treatment tank 40 is provided with a slow flow Component 41, the slow-flow component 41 includes slow-flow fixing rods 411 arranged on two opposite inner walls of the waste water treatment tank 40, the positions of the two slow-flow fixing rods 411 are corresponding and both are horizontally arranged, and the two slow-flow fixing rods 411 are connected with The slow flow arc plate 412, the middle part of the slow flow arc plate 412 is a vertically arranged plate protruding to one side to form a convex arc surface. Arc-shaped slow-flow sub-plate 413 is arranged. Wastewater treatment tank 40 is filled ...

Embodiment 3

[0073] The further optimization scheme of present embodiment on the basis of embodiment 1 is: see appendix Figure 13 As shown, the air intake chamber 16 is provided with a filter screen 50 arranged horizontally, and the pipe body air inlet of the second pump body 17 is set at the filter screen 50, and the filter screen 50 is provided with a folded The curved guide plate 51 is bent, and the bent part of the upper end of the guide plate 51 is inclined upward to guide the airflow to flow upward. The guide plate 51 is arranged near the air inlet of the air intake chamber 16. The height of the air inlet of the pipe body of the second pump body 17 corresponds to the bending portion at the upper end of the deflector bend plate 51 . Through the filter screen 50 provided in the intake chamber 16, the airflow sent into the interior of the intake chamber 16 can be preliminarily filtered, and the fluff and other floating objects in the filtered airflow can be relatively reduced, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com